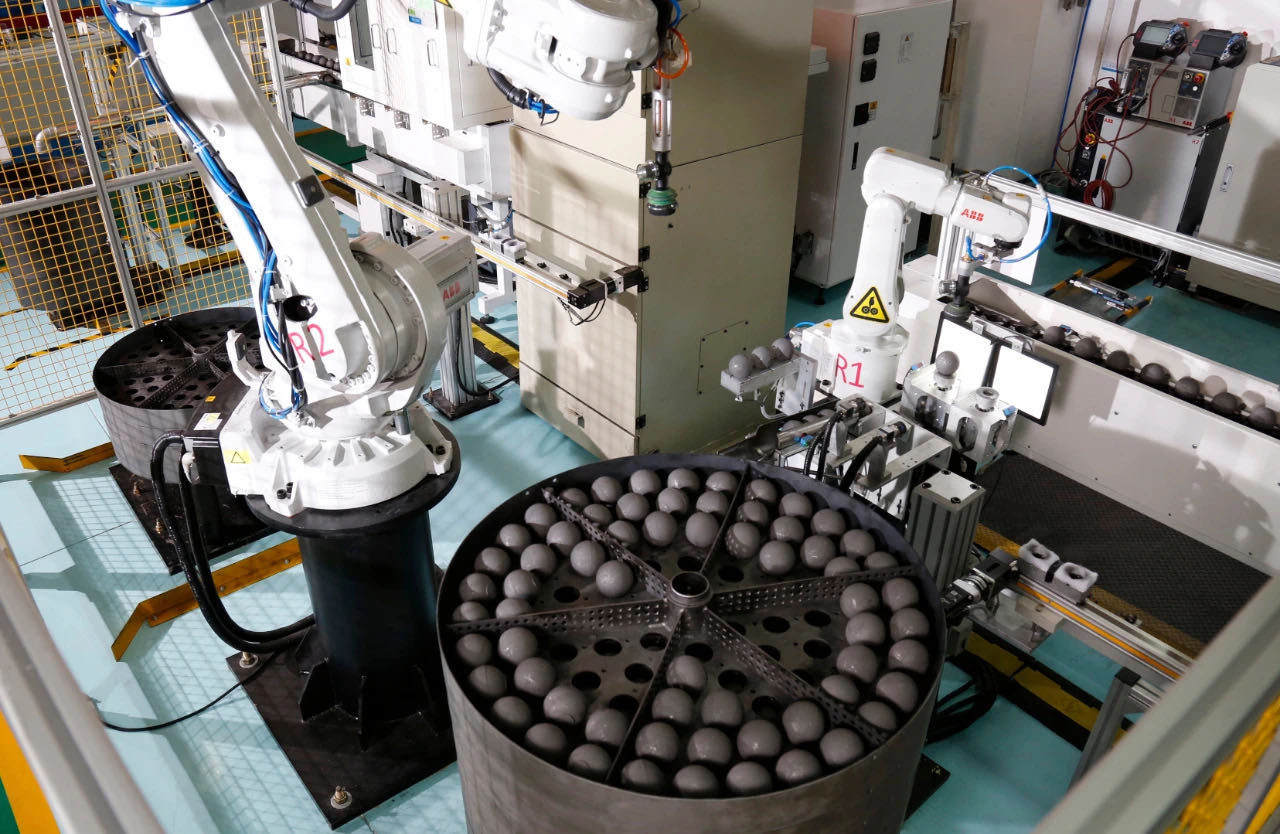

On January 9, the first batch of products of the world’s first industrialized high-temperature gas-cooled reactor nuclear fuel element production line with independent intellectual property rights in my country was shipped from China National Nuclear Corporation North Nuclear Fuel Element Co., Ltd. and sent to the high-temperature gas in Shidao Bay, Rongcheng, Shandong. The cold reactor nuclear power plant demonstration project provides fuel power for its subsequent grid-connected power generation.

The high-temperature gas-cooled reactor nuclear power plant demonstration project is one of the major national science and technology projects. The construction started in December 2012 and is constructed and operated by Huaneng Shandong Shidaowan Nuclear Power Co., Ltd. , The company’s tripartite shareholders include Huaneng Nuclear Power Development Co., Ltd., Nuclear Construction High Temperature Reactor Holding Co., Ltd. and Tsinghua Holdings Co., Ltd. under China National Nuclear Corporation. The demonstration project has completed the dual-reactor cold test and entered the dual-reactor hot test stage. The number of spherical fuel elements sent to the demonstration power station is 78,000, which is part of the first delivery of 870,000 spherical fuel elements. These spherical fuel elements are expected to formally enter the reactor in April this year.  Different from the current global mainstream pressurized water The high-temperature gas-cooled reactor is one of the candidate reactor types in the fourth-generation nuclear energy system recognized in the international nuclear energy field. The pebble-bed modular high-temperature gas-cooled reactor adopts all-ceramic-coated pelletized spherical fuel elements, helium gas as the coolant, and graphite as the moderator. It has good inherent safety and can ensure that the reactor core does not melt and undergo any accident. Mass release of radioactivity.

Different from the current global mainstream pressurized water The high-temperature gas-cooled reactor is one of the candidate reactor types in the fourth-generation nuclear energy system recognized in the international nuclear energy field. The pebble-bed modular high-temperature gas-cooled reactor adopts all-ceramic-coated pelletized spherical fuel elements, helium gas as the coolant, and graphite as the moderator. It has good inherent safety and can ensure that the reactor core does not melt and undergo any accident. Mass release of radioactivity.

Spherical fuel elements are an important basis for the inherent safety of high-temperature gas-cooled reactors, and their manufacturing technology is the main technical challenge for the development of high-temperature gas-cooled reactors. The supporting construction project of the national major scientific and technological project “Large-scale advanced pressurized water reactor and high-temperature gas-cooled reactor demonstration project”-China Nuclear North High-temperature gas-cooled reactor nuclear power fuel element production line is the world’s first and only industrial-scale spherical fuel element production line , my country has completely independent intellectual property rights. The production line is designed to produce 300,000 spherical fuel elements per year.  According to Baotou Daily, the production line was launched in 2004 Preparatory construction, construction officially started in March 2013, production was formally put into production in March 2016, product qualification appraisal was passed in August 2016, and the 200,000th spherical nuclear fuel element rolled off the assembly line on July 17, 2017, fully reaching the design capacity. From the initial production qualification rate of coated fuel pellets to only 30%, it has increased to 97.84% today; from the initial fuel pellet production 11More than 1,000 pieces, and later produced more than 17,000 pieces per month, and later the production capacity exceeded 35,000 pieces, and the pass rate increased from the initial 95.5% to the current 99.18%.

According to Baotou Daily, the production line was launched in 2004 Preparatory construction, construction officially started in March 2013, production was formally put into production in March 2016, product qualification appraisal was passed in August 2016, and the 200,000th spherical nuclear fuel element rolled off the assembly line on July 17, 2017, fully reaching the design capacity. From the initial production qualification rate of coated fuel pellets to only 30%, it has increased to 97.84% today; from the initial fuel pellet production 11More than 1,000 pieces, and later produced more than 17,000 pieces per month, and later the production capacity exceeded 35,000 pieces, and the pass rate increased from the initial 95.5% to the current 99.18%.

As my country’s first nuclear fuel element plant, China Nuclear North Nuclear Fuel Element Co., Ltd., which was built in 1958, is located in Baotou City, Inner Mongolia Autonomous Region. The successful research and development has made important contributions, and it is currently the most comprehensive nuclear fuel and nuclear material production and scientific research base in China.