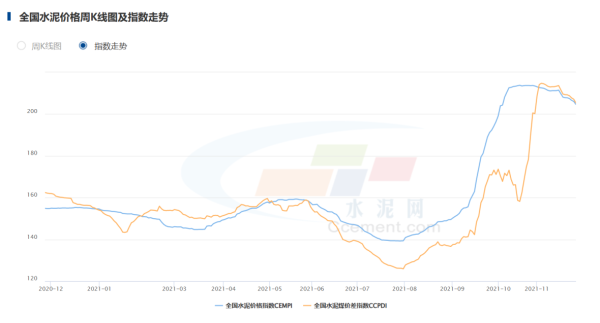

Entering November, cement prices have entered an adjustment period after experiencing a spike during the “Golden Nine and Silver Ten” period.

According to data from China Cement.com, cement prices across the country fell significantly in November. Among them, Hubei, Guangdong and other regions experienced the largest declines, down about 100% from their highs at the end of October. Yuan / ton.

This year, cement prices fluctuated significantly. The monitoring data of China Cement Network shows that the average price of ordinary Portland cement (P.O42.5 bulk cement) in late July was about 422 yuan/ton, reaching a historical low. The price began to continue to rise in early August. The average price of salt cement (P.O42.5 bulk cement) reached 649 yuan/ton, a cumulative increase of more than 50%.

Compared with the beginning of November, the average price of ordinary Portland cement (P.O42.5 in bulk) dropped by 13.1 yuan/ton, reaching 585.7 yuan/ Ton.

Image source: China Cement Net

From the supply side, cement production is also declining. According to the National Bureau of Statistics, the national cement output in October was 20.14 million tons, a year-on-year decrease of 17.1% and a month-on-month decrease of 1.78%. Judging from the national mill start-up load data, it is expected that the national cement output in November will fall by about 15% year-on-year and by about 4% month-on-month.

The overall cement industry nationwide is dominated by production reductions. In November, the clinker production lines in Northwest, Northeast, and North China began to produce staggered peaks. Cement companies in most provinces in East China, Southwest, and Central South, in order to reduce coal consumption, electricity consumption, and ease supply pressure, clinker line grinders have also stopped kilns and reduced production.

From the demand side, due to the tightening of real estate regulation and the sudden cooling of financing, the cold real estate will affect the demand for cement. The real estate industry is a “barometer” of the cement industry, and its start-up affects cement demand. From January to October, the newly started area of real estate fell by 7.7% year-on-year, and the area purchased by real estate development companies fell by 11%.

In addition, thermal coal is the main energy consumable in the cement production industry, and its price can directly affect the cost of cement production. It is estimated that every ton of water produced on averageMud needs to consume about 100 kilograms of thermal coal. Therefore, if the price of thermal coal drops by 100 yuan per ton, the cost of cement will fall by 10 yuan per ton.

As the National Development and Reform Commission began to issue documents successively in October, taking multiple measures to ensure the supply of coal and stabilize the price, coal prices have returned to a reasonable level. At the beginning of November, the closing price of 5,500 kcal thermal coal in the Bohai Rim port fell below 1,200 yuan/ton, and the price of 5,500 kcal thermal coal in the Shanxi, Shaanxi, and Inner Mongolia regions fell below 1,000 yuan/ton. Since mid-November, the price of 5,500 calories in Shanxi and Shaanxi has been limited to 900 yuan/ton.

In this context, the cost of cement production has dropped by about 31% compared to the peak in mid-October, providing room for cement price reduction. As the central government has repeatedly released signals of easing real estate financing, the property market at the end of the year, driven by policies, blew a “warm wind”, and the demand for real estate construction next year is expected to improve.

The “China’s Listed Companies Carbon Emission Ranking (2021)” jointly released by Caijing Magazine and China Venture Carbon Investment shows that the emission intensity of the power and cement industries is far greater Higher than other industries.

Currently, the cost of coal and electricity accounts for more than half of the total cost of cement. Under the goal of “dual energy consumption control” and “carbon reduction”, the cement industry’s future production costs will It is getting higher and higher, how to enter the field of clean energy such as photovoltaics and to reduce carbon and cost through technology research and development is the key to the development of the cement industry.