According to Reuters news on May 6, the global power battery leader Ningde Times New Energy Technology Co., Ltd. (300750, hereinafter referred to as Ningde Times) has entered the final review stage for the site selection of the US power battery factory.

CATL’s U.S. plant will reportedly supply BMW and Ford, with potential locations including Kentucky and South Carolina. BMW has an auto plant in South Carolina and Ford has two plants in Kentucky. If a South Carolina plant is established, the goal is to start producing batteries in 2026, the sources said.

It was previously reported that CATL plans to build a power battery factory in the United States, with a total investment of up to 5 billion US dollars (about 31.8 billion yuan), The target annual production capacity is about 80 GWh, and the scale of employees reaches 10,000.

Regarding the above news, the relevant person in charge of CATL told the news (www.thepaper.cn) reporter that they would not comment.

On May 5, Zeng Yuqun, chairman of CATL, said at the 2021 annual performance briefing that CATL is discussing with all mainstream overseas car companies how to meet the needs of localized production. Landing service. Zeng Yuqun responded to the rumors of building a factory in North America: “The company has discussed various possible supply and cooperation plans with American customers, as well as the possibility of localized production, but the specific situation needs to take into account factors such as worker training, efficiency, and labor unions. The impact on quality and cost.”

CATL built a factory in the United States for the first time, taking a key step in its own globalization process. In September 2019, CATL announced that it would invest 1.8 billion euros to build its first overseas factory in Thuringia, Germany. In April this year, the plant in Thuringia, Germany, officially obtained the 8GWh battery cell production license. It is expected to reach the planned production capacity of 14GWh after the end of this year.  Previously, it has been rumored many times that the Ningde era may become Apple’s Apple Car supplier. According to media reports, CATL, BYD and Apple stalled in the battery supply negotiations in the car-building project because CATL rejected Apple’s request to build a battery factory in the United States and form a cooperative development team.

Previously, it has been rumored many times that the Ningde era may become Apple’s Apple Car supplier. According to media reports, CATL, BYD and Apple stalled in the battery supply negotiations in the car-building project because CATL rejected Apple’s request to build a battery factory in the United States and form a cooperative development team.

As the world’s second largest automobile market, the current power battery market in the United States is still dominated by Japanese and Korean battery manufacturers. Tesla’s battery supplier is Panasonic, GM’s battery supplier is LG New Energy, and Ford’s battery supplier is SK On. This partnership has been going on for many years.

As one of CATL’s customers, BMW said in a statement that the company is deeply studying the possibility of building a battery factory in North America and sourcing in the region Battery materials, “We are negotiating with several partners on this matter.” Other customers of CATL, including Tesla, Volkswagen, and Ford, declined to comment.

In addition to CATL, Asian battery manufacturers planning to build factories in the United States include South Korea’s LG New Energy, SK On and Samsung SDI, and Japan’s Panasonic. According to reports, Japan’s Panasonic plans to spend billions of dollars to buy land to build a factory to supply high-capacity lithium-ion batteries for Tesla.

As of now, LG New Energy has announced the construction of more than three joint-venture power battery factories in North America with General Motors, a joint-venture battery business with Hyundai Motor, and announced plans Joint venture with Stellantis Group. According to LG’s new energy plan, by 2025, the annual battery capacity in North America alone will exceed 200GWh.

SK On and Ford announced plans last year to build two battery plants in Glendale, Kentucky. According to Korean media reports on May 5, Hyundai Motor and SK On are in talks to establish a joint venture battery factory in the United States, or choose a location in Alabama or Georgia.

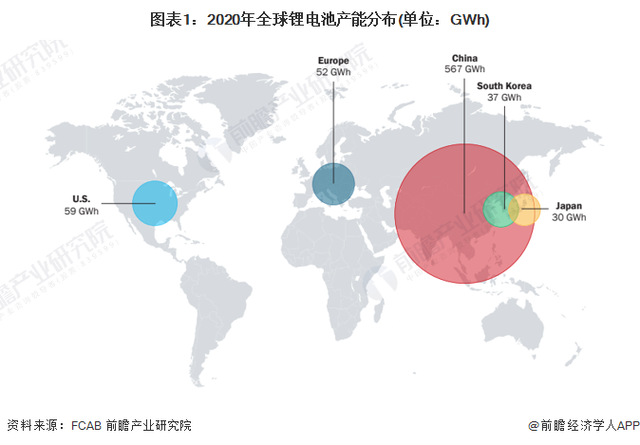

The data analyzed by Cui Dongshu, Secretary General of the National Passenger Vehicle Market Information Joint Association, show that the penetration rate of new energy vehicles in the world generally shows a rapid upward trend, and the penetration rate of new energy vehicles in the United States in 2022 The rate is 6%. However, the United States lags far behind Asian countries in the layout of power battery production. According to the data of the Federal Advanced Battery Alliance (FCAB), the global lithium battery production capacity in 2020 is about 747GWh, and the Chinese market accounts for 76%. The US market is only 59GWh, accounting for 8%.  Local time on May 2, U.S. Department of Energy Announced that the administration of US President Biden will invest $3.16 billion to increase domestic battery production and strengthen the supply chain in the United States. Biden administration wants U.S. sales by 203050% of the vehicles sold are electric vehicles. This infrastructure investment mainly supports new construction, renovation and expansion of commercial facilities, as well as production demonstrations and battery recycling. It will attract power battery manufacturers and battery raw material manufacturers from around the world to build factories in the United States.

Local time on May 2, U.S. Department of Energy Announced that the administration of US President Biden will invest $3.16 billion to increase domestic battery production and strengthen the supply chain in the United States. Biden administration wants U.S. sales by 203050% of the vehicles sold are electric vehicles. This infrastructure investment mainly supports new construction, renovation and expansion of commercial facilities, as well as production demonstrations and battery recycling. It will attract power battery manufacturers and battery raw material manufacturers from around the world to build factories in the United States.

CATL has been in fierce competition with Korean battery manufacturers in overseas projects since 2018. Beginning in 2021, CATL will mass-produce and deliver power battery products in overseas markets. Zeng Yuqun said that overseas customers hope that the company’s next fixed-point cycle will start, that is, after 2026, or even to 2035, to increase the proportion of supply and become its major supplier.

Consulting firm Wood Mackenzie said CATL is on track to more than triple its battery manufacturing capacity by 2025. It is understood that in 2021, the production capacity of Ningde era lithium-ion batteries will be 170.39GWh, and its production and sales will be 162.3GWh and 133.41GWh, respectively.

On May 5, CATL issued a prospectus for fixed increase. The raised funds of 45 billion will be used for the construction of five expansion projects, which will add new lithium batteries. The annual production capacity is about 135GWh. At present, the total designed annual production capacity of the lithium battery production lines that have been completed and put into operation in CATL will reach 260GWh-280GWh. According to CATL, the company’s battery production capacity will reach more than 670GWh by 2025.

Affected by the decline in profits in the first quarter of 2022, the stock price of CATL fell 8% on May 5, with the largest intraday drop hitting a new low in nearly a year. On May 6, the stock price of Ningde Times opened lower and moved higher, and finally closed at 375.99 yuan, with a total market value of 876.4 billion yuan.