As an electric vehicle brand under the Great Wall, Euler’s models have always been small and smart, with bold design and main city commuting as its unique selling point.

Battery is the core component of electric vehicles. Many auto companies do not have the ability to conduct self-research. The domestic market basically relies on suppliers such as Ningde era to provide batteries, and the cost is high.

In order to put technology in his own hands and to effectively control costs, Great Wall Euler decided to invest heavily in the research and development of power batteries, and he did not hesitate to build the Great Wall Euler Honeycomb Energy Technology Center.

The project has invested 1.33 billion and plans to achieve 26 billion R&D investment in 2025. Honeycomb Energy has a research and development team of 3,000 people, more than 350 foreign experts and more than 1.6 billion R&D facilities.

The official said that Great Wall Euler has the entire industry chain layout capability from element to battery pack manufacturing to vehicle manufacturing and ladder recycling.

Return to the product, the energy density of the Euler brand power battery is 160Wh/kg, the battery energy is 33kWh, and the Euler R1 NEDC cruising range can be 351km.

The battery pack of Euler R1 uses a square aluminum case with a ratio of 523. The cell gap is extremely small, and the aluminum package material is lighter in weight, ensuring high energy density and light weight. Quantitative characteristics.

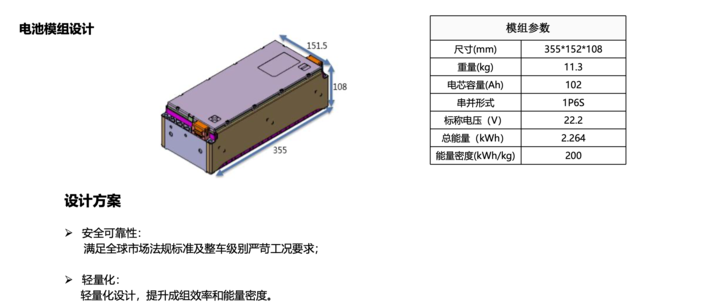

The battery module is designed with 6 strings. The battery pack has 15 modules, 1 and 90 strings. The single module weighs 11.3kg and has a total energy of 2.26kWh. Modules also focus on lightweight design to improve group efficiency and module energy density.

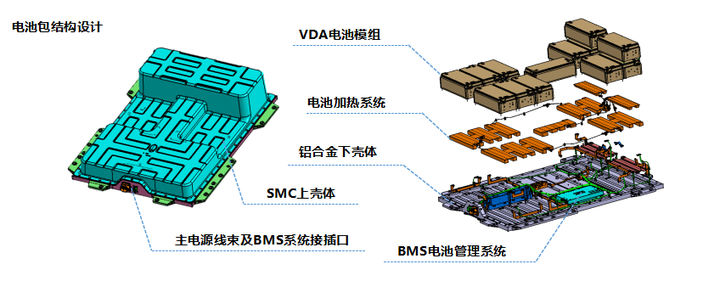

The upper casing of the battery pack is made of SMC composite material, which has the characteristics of insulation, pressure resistance, anti-corrosion, explosion-proof, fireproof, high strength and light weight;

The lower case is made of aluminum profile welded by friction stir welding and CMT and TIG welding, which also ensures strength and rigidity, while balancing light weight;

In terms of sealing, the battery pack is sealed with silicon foam between the upper and lower housings to meet the requirements of the battery pack IP67 and water immersion test.

At the same time, the rest of the components are also lightweight design. For the car like Euler, the design of the battery pack pays attention to the “lightness and not break” under the premise of ensuring the strength.

As far as safety is concerned, we understand that Euler can perform real-time detection of cell voltage and total voltage, including low-voltage power supply detection and temperature detection, as well as battery status detection in the event of an accident. Turn on the power failure protection.

Electric vehicles pursue intelligent charging and discharging, which relies on a clever BMS battery management system to predict the state of the battery. It is understood that Euler R1 can comprehensively estimate the SOC, SOE, SOF, SOH, etc. to ensure that the equalization function is turned on to adjust the consistency of the battery and the good charge and discharge function.

In addition to this, the system will also have basic charging time estimation, remote monitoring and UDS diagnostic functions to achieve scientific charging and discharging.