The more mature a company is, the more it will focus on the supply chain.

Editor’s note: This article comes from “ Future Car Daily ” (WeChat public account ID: auto-time), author: Li Huanhuan.

Source: electrek website

Author | 李欢欢

Edit | Xu Yang

A super battery with a life span of “million miles” may be coming.

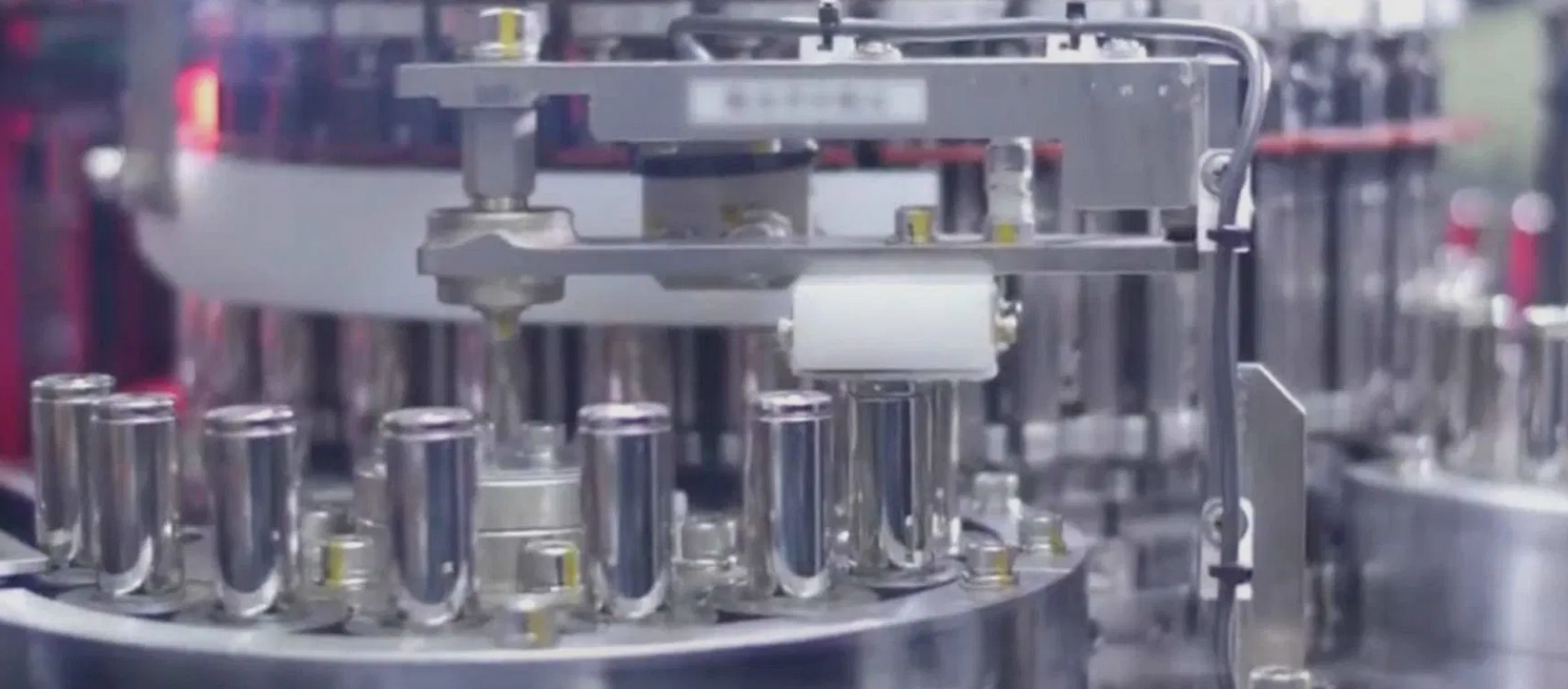

Recently, the electrek website reported that Tesla is building a pilot battery production line at its Fremont plant in the United States. Unlike a battery factory operating in Nevada, Tesla has designed its own battery production equipment, meaning it will produce its own battery products independently.

In April 2019, Tesla CEO Elon Musk announced that it is expected to launch a battery with a service life of more than 1 million miles in 2020. Now that Tesla is building a battery production line, it may be to reserve capacity for super batteries.

Car companies’ entry into the battery field is nothing new. Mercedes-Benz owns or is constructing nine battery plants in Europe, Asia, and North America. The battery plant jointly established by Volkswagen and Swedish battery company Northvolt is expected to start production in 2024. Car companies such as BAIC, SAIC, Changan, and Geely have also established their own battery factories.

The performance and supply of batteries affect the development of electric vehicles. Not long ago, due to the shortage of LG Chem’s battery supply, Jaguar was forced to close the I-Pace production line, and Audi and Mercedes-Benz also cut their production targets for the Audi e-tron and Mercedes-Benz EQC models respectively.

Mastering battery production and improving battery technology can also help control the cost of electric vehicles. In addition to self-produced batteries, Reuters reports that Tesla will also cooperate with Ningde Times to use lithium carbonate batteries to reduce vehicle costs.

When Tesla’s electric car was first born, it attracted the attention of many people with its cool products. Today, Tesla has become the second-largest car company by market value. It needs to continue to produce enough attractive cars. Products also need to do everything traditional car companies have done, such as improving the supply chain, such as reducing costs and increasing efficiency. forBattery attention is exactly the embodiment of Tesla’s next transformation.

The battery must be first too

Tesla intends to produce its own batteries, but it has a clue.

On February 5, 2019, Tesla announced the acquisition of a 79% stake in Maxwell, a supercapacitor manufacturer. It is reported that Maxwell’s new lithium-ion electrode technology can make the battery energy density exceed 300Wh / kg, or even 500Wh / kg, and this number is increased by 15% -25% in a cycle of 2-3 years. At the same time, battery cost Will reduce by 10% -20%.

A short time later, Musk announced that Tesla may launch a new battery with a service life of “million miles” in 2020. Many people ridicule Musk for being “whimsical” and a “liar.”

However, a professional test report proves that Musk is not bragging.

A person familiar with the matter revealed that Jeff Dahn, a member of the Canadian Academy of Sciences, a professor at Dalhousie University in Canada, and an internationally renowned battery research expert, and his laboratory are working on a new battery for Tesla. This is a lithium-ion battery with a next-generation “single crystal” NMC cathode and a new advanced electrolyte.

According to the test results of this battery released by Dahn Labs, this new lithium-ion battery can provide more than 1 million miles of power for electric vehicles.

Tesla set up a battery manufacturing team after having the technology reserves.

In September 2019, Tesla released a job posting, “Finding Technicians for a Production Line Under Development”, with specific positions for battery manufacturing technicians, analysts, and testers. Fremont and Colorado.

Why is Musk so dedicated to making his own batteries?

Perhaps, Musk ’s speech at last year ’s Tesla shareholder meeting could explain all of this, “If I am an external investor, I will pay close attention to Tesla ’s plans to expand battery production scale and reduce unit battery costs.”

Tesla ’s batteries have always been supplied by Panasonic. As Tesla ’s sales have risen, the problem of insufficient battery supply has gradually become apparent. Musk has tweeted and complained: “The annual output of the Panasonic battery production line in the super factory is only For 24GWh, the production of Model 3 has been limited since July 2018.

How much money can the Model 3 save?

In fact, not only the Fremont plant, but also comprehensive media reports such as the electrek website and the Global Times, Tesla has battery production plans at its Berlin plant in Germany and Shanghai super plant. At present, Tesla’s Shanghai battery factory has begun construction.

Recently, Industrial Securities released a research report showing that after Tesla adopted a domestic supply chain, the domestic Model 3Will have 27% -34% price reduction space. At present, the domestically sold Model 3 subsidized finished price is 299,905 yuan. If the price is reduced by 27% -34%, its minimum price may be reduced to 197,000 yuan.

Model 3 source: Tesla’s official Weibo

This estimate does not take the battery into account. What if Tesla batteries are self-sufficient and localized? Which range will the price of domestic Model 3 fall?

The previous year’s performance report disclosed by Ningde Times shows that the installed capacity in 2019 is 31.71GWh, and the company is expected to realize a net profit of 4.064 billion-4.911 billion yuan in 2019, a year-on-year increase of 20% -45%.

There are three major business segments in the Ningde era: power battery systems, energy storage systems, and lithium battery materials. Power battery systems are the main source of revenue, accounting for about 80%.

If the net profit is estimated at 4 billion yuan, the profit of the battery sector is about 3.2 billion yuan, and the average profit per GWh is about 109.9 million yuan.

At present, the domestic Model 3 has a battery capacity of 60kWh, and the profit of each set of batteries assembled by Ningde Times is about 60 thousand yuan.

A rough estimate is that if the domestic Model 3 can be equipped with local self-produced batteries, the lowest selling price may further drop to 191,000 yuan.

Usually, 200,000 yuan is regarded as the price ceiling of its own brand, which is reduced to less than 200,000 yuan. In addition, with the blessing of Tesla’s brand, if the production capacity is sufficient, the domestic Model 3 should quickly win the sales champion.

In 2019, the domestic new energy vehicle sales champion is BAIC New Energy EU Series, with a cumulative sales of 110,000 units. This car has already faced the global market with the imported Model 3. According to data released by EV Volumes, last year, the cumulative sales of imported Model 3 were 301,000 units, which is 2.7 times that of BAIC New Energy EU series.

Participating in battery competition

At present, auto companies build their own battery factories. The initial goal is to meet their own battery needs. But if you only supply to your own car, it may not be cost-effective for auto companies to produce their own batteries.

In August 2018, Nissan Motors officially announced the sale of its electric vehicle battery manufacturing unit to VisionGroup, of which Nissan retains 25% of the shares. In this regard, Nissan said that it will focus more on the development of electric vehicles in the future. Nissan, which has taken the lead in electrification, may think that it is more cost-effective to hand over battery production to a third party.

For many years, BYD has adopted a closed strategy of self-production and sales of power batteries. The Ningde era later led to BYD to re-examine itself. On March 31, 2018, Shen Ye, the deputy general manager of BYD’s lithium battery business unit, said in a public speech that BYD is spinning off the power battery business and will be split into the market in the future. At the same time of independence, BYD Power Battery has gradually been opened to other car companies, and news shows that it has already supplied passenger car companies such as Jinkang New Energy and Changan.

Musk is an ambitious person. The purpose of making batteries must not only be to meet the needs of Tesla. During the fourth-quarter 2019 earnings call, Musk said that he would increase battery production to today’s “unbelievable crazy level.” Ningde Times, which won the Tesla order, also issued risk predictions in succession, saying that the impact of the cooperation agreement with Tesla on the company’s future operating performance is still uncertain.

Re-examining Tesla as a battery supplier is still a terrible rival.

Some analysts believe that the direction of Tesla’s battery will be weight reduction, volume reduction and capacity expansion. At the end of 2018, analyst firm UBS released a report showing that the cost of lithium batteries jointly developed by Panasonic and Tesla was $ 111 / kWh (about RMB 777.8 yuan / kWh), and the cost of Ningde Times was $ 155 / kWh (about RMB 1086.2 / kWh).

Cobalt-free lithium iron carbonate battery, which is under discussion with Ningde Times, can further reduce battery cost. A source involved in the negotiations told Reuters that lithium iron phosphate batteries are “double-digit percentages” cheaper than Tesla’s current batteries. The industry generally believes that Tesla’s battery cost will exceed $ 100 / kWh.

In addition to reducing costs, the “Million Miles” super battery can make electric cars have the same battery life as traditional cars.

Testing shows that the battery capacity of a 1 million-mile battery has dropped to 95% of the new battery state after 1,000 discharge cycles, and still has a 90% service life after 4,000 discharge cycles. At present, the battery life of ordinary power batteries is reduced to 80% after 1,000 cycles of charging, and a maximum of 2,000 discharge cycles can be used.

That is, the million-mile super battery has at least twice the life of existing batteries, and battery life will not be a bottleneck for electric vehicles.

Musk has said that the drive system and body design of the Model 3 are similar to commercial trucks, with a design life of up to one million miles, equivalent to 1.6 million kilometers, while ordinary private cars can only travel 20,000 kilometers per year. In other words, a Tesla with a million-mile super battery,”Can be used for a lifetime”.