How can the new forces of car-making survive.

Editor’s note: This article comes from the WeChat public account “Brain pole body” (ID: unity007) / a>, author sea monster.

After seven months of hard work, Jia Yueting, who built a car in the US, finally went bankrupt.

Official bankruptcy, for Jia Yueting, has become one of the few good news in recent years. This means that Jobs will take out the only Faraday Future (FF) shares in his hands and transfer them to creditors, and he will be able to continue the FF project. In case the FF is saved in the future, the debt can be paid off and turned over again.

What about those creditors? For at least four years, he can no longer chase down the debts, but he must change his mind and become a shareholder of this car company who lives on the front line. He and Jacobs have suffocated their dreams for a long time.

And in October last year, Sir Dyson, who was on the British Isles across the ocean, wisely declared that he had failed to build a car after spending £ 500 million over three years. But this is not another version of “PPT car”. At least not long ago, the stubborn Dyson still exposed this “most expensive” Dyson electric car, and it really became a “closing masterpiece” “.

Investment is bottomless, and business prospects are not visible. This is the main reason why Dyson gave up when he was over addicted. In contrast, Jobs, who has only one FF card in his hand, still chooses to be desperate and is still struggling to find a large investment that can mass-produce FF. If you find the money, can you really turn Gibbs over again? At that time, the FF, which surprised everyone, was now a bit “awesome,” but with a price of $ 200,000, can you still find consumers who pay for his “dream”?

Looking back to China, the lack of money and finding money has always been the “new normal” of these new forces of “cross-border car manufacturing” in China. However, getting money is only the first step on the road to making a car, followed by a series of difficulties in mass production, technology, operation, quality, after-sales, etc., waiting for these new forces to “subvert” the automotive industry to solve.

If Dyson and FF are just two small samples of “cross-border car manufacturing”, then what is the general difficulty of “cross-border car manufacturing”?

As long as you do n’t lose money, can you successfully build cars across borders?

The trend of “cross-border car-making” really got up, Should start with Tesla. The myth of how Musk uses “first principles” has been circulating on the Internet. It is said that after understanding the battery technology and the cost of materials, Musk is determined to build a pure electric car, because he can’t wait for the “electric cars of traditional car companies”.

Tesla ’s success after 2012 and 2013 has made many admirers in our country see the possibility of “tribute”. More importantly, after 2014, driven by favorable policies, new energy vehicles ushered in a new blue ocean with unlimited market potential. In addition to those Internet newcomers who are eager to try, many giants in the physical industry have also invested heavily in the market. In addition to seeing the main business of the ceiling, they have opened up a growth point of 100 billion scale.

In the words of real estate tycoon Xu Jiayin, “We are all talking about 100 billion things now, and we will not talk about hundreds of millions of things.”

In this wave of “new forces” of cross-border car manufacturing, there are Internet people who are relatively close to the car, such as Li Bin, the Internet car media person who founded Weilai Automobile, and Li Xiang, who founded the ideal car home. He Xiaopeng, the Internet person who founded Xiaopeng Automobile, and Jia Yueting, the head of the constant LeTV; there is also a wave of executive founders who have worked hard for many years in car companies, such as Shen Hui from the traditional car company founded Weimar, and the founding of Volvo Fu Qiang of Aichi Automobile etc.

More “cross-border players” that are familiar to the outside world are the celebrities and star companies that everyone is more familiar with. For example, Dong Mingzhu, the head of Gree Electric. After the failure to acquire Zhuhai Yinlong at the company level, she personally invested 1 billion in Yinlong. Last year, Miss Dong led Gree Electric and Weimar Automobile to reach a strategic cooperation. At the same time, she also established a Guochuang Energy Internet Innovation (Guangdong) Co., Ltd., which shows the great determination to enter the new energy vehicle.

The representative of the cross-border real estate industry is Xu Jiayin of Evergrande Group, determined to invest 45 billion in Evergrande New Energy Vehicles in the next three years. Previously, Evergrande had invested nearly 30 billion yuan in companies such as FF, NEVS, Shanghai Kanai New Energy, and Tate Mechanical & Electrical Co., Ltd. In the list of real estate car manufacturing, Baoneng, Country Garden, China Fortune, Wanda, R & F and other companies are behind the Evergrande. These companies almost all announced their entry into new energy vehicles with a “not bad money” attitude. Buy, buy, buy or vote to get a ticket to build a car.

What is more unexpected is that Wuliangye Group bought a 51% stake in Kaiyi Automobile for 2.491 billion yuan. Kaiyi itself is an edge model of the original Chery. At the end of last year, a new car was first mass-produced after Wuliangye became a shareholder.The model is put into production and is expected to be officially sold this year, but the prospect is really not optimistic. For a traditional winery to enter the new energy car, it is no wonder that some netizens ridiculed that “the amount of wine is not good, I am embarrassed to drive this car.”

It’s not bad money, it’s usually the confidence of these newcomers. But once you really invest in two or three years, you will understand the meaning of “making a car is burning money”. When Wei Lai’s Li Bin kindly reminded people who wanted to enter the industry to say “Don’t build a car without 20 billion”, Lord Dyson told everyone with a vivid case, even if it costs 20 billion (actually only spent more than 4 billion to retreat with difficulty ), And may eventually fail.

In addition to overcoming the difficulty of burning money, cross-border car manufacturing, what other fatal problems do we have to face?

Burning money may be able to make a car, The sales and production volume is the key to survival

The reason why Dyson gave up making cars decisively is not another case of “PPT car making” failure. Rather, from the performance of the newly exposed new car, 960 kilometers of battery life can hang all the existing electric Cars, even most fuel cars.

The design with no buttons in the car and the HUD instead of the central control screen completely subverts the existing design habits. The rigid style of the Land Rover, the extra-long body and the low-angle Ferrari windshield also have Luxury car style.

The main reason for abandoning car manufacturing is because of the high research and development costs and the cost of car manufacturing, so that the basic price of each car reaches 150,000 pounds, which is about 1.3 million yuan. If you add the cost of profits and import duties, the price will be so high that you ca n’t find a friend.

Control the cost of unit price, realize mass sales, and thin the cost of bicycles again to win the market. This is almost the iron law of the traditional automobile industry. But this common sense turned out to be “invalid” at the beginning of the new car-making forces.

Special mention is made of azure cars that build and sell cars on the Internet. Wei Lai has adopted a direct management system that completely revolves around end users. As long as you are willing to spend a lot of money to become a Weilai car owner, you can enjoy life-long power replacement, thousands of miles of power transmission, exclusive WeChat group, 24-hour customer service and so on. ‘S luxury experience store is also trying to build 500 charging stations across the country.

In order to achieve this “superior” experience, Wei Lai has accumulated more than 20 billion losses in the four years since its establishment. It is said that if one ES8 is sold, 920,000 will be lost. If you continue to play in Weilai’s mode, you will need to sell at least 400,000 units to stop losing money.

But to account for the cost of subsequent car owners ’services, this is probably a money-burning road that will never see the end. Once the avid capital market is “excited”, it is easy to be illogicalOnly tell stories, but still have to face reality when you calm down.

2019 will be the year of life and death for a new force in car manufacturing. The capital market has released a ruthless saying: No new car-making force is worth investing in. At the same time, Tesla, which is regarded as a “mentor” by the new car-making forces, is accelerating its pace in the Chinese market. Tesla’s localization has landed and become a tiger and wolf rival of these car companies.

The capital market has left Tesla 15 years for profit, and how many years has Tesla left these apprentices?

After experiencing a series of water rebellions last year, almost in the spring when the epidemic began. Fortunately, last month, he just received 7 billion yuan of “life-saving money” from the Hefei city government to renew his life.

But should the government support give Wei Lai the opportunity to continue to verify its business model? I am afraid this money is mainly used for Weilai’s self-built production line in Hefei. The fundamental purpose is still to promote Hefei’s economy and employment.

We know that in 2019, the national new energy subsidy has declined by 70%, which has caused domestic new energy vehicle companies that can only make a little profit from the state subsidy into a collective panic. The arrival of the epidemic once again allowed Guobu to continue for 2 years, and various governments have also invested in many new energy vehicle companies that have fallen into operating difficulties.

This means that from “policy support” to “market-led” industrial transformation, the two-year pause button is pressed, while also giving the new car-making forces a two-year buffer period. If during this period, the cost of car manufacturing and services cannot be reduced, and the price of the entire vehicle can be controlled within the acceptable range of consumers, while maintaining sufficient superior performance, it means that it is difficult to stay in this short window period. Later survived.

Besides, Tesla is fully promoting localization in China, because the replacement rate of domestic parts has repeatedly increased, and prices will drop significantly. Musk is already realizing the third step of his car-building logic by making Tesla a civilian by drastically reducing costs. If you buy a pure electric car in the range of 200,000 to 300,000, why do consumers not work hard to drive a Tesla home?

So what preparations need to be made for a new energy electric vehicle to be able to produce and sell?

Return to common car manufacturing knowledge: do a good job in technology, manufacturing and operation

In such a difficult start in 2020, we really do n’t want to “get down the road” to companies and entrepreneurs who have already made cross-border car manufacturing in China, or are preparing to cross-border car manufacturing. So, let ’s not talk about cross-border real estate developers who use cars to make moneyWe do n’t talk about speculators who sell shells for fraudulent compensation, financing, or qualifications, nor the subversion of the Internet and the national feelings of self-made cars. We also need to talk about the basic common sense of car making.

We know that the automotive industry is a traditional industry in which capital, technology, and talent are all known for their economies of scale. Its true core value lies in automotive manufacturing technology and manufacturing process systems. This is precisely the core competitiveness of traditional big-name car companies that have accumulated technology for decades or even hundreds of years.

Although the development of electric vehicles is a matter of the past two decades. Compared with fuel-powered vehicles, the “three power” technologies of electric vehicles are significantly less difficult, giving electric vehicle companies an opportunity to “subvert” the traditional automobile industry, but this does not mean that they can innovate without respecting laws and common sense. A service model of Internet thinking can be successful by “burning money”, not to mention that by taking advantage of policies, we can get fish in muddy water.

A mainstream car company, no matter how old or new, must first create a high-yield and high-selling model that can be popularized at a cost-effective price. The key to creating high-quality products is still inseparable: the accumulation of core technologies, manufacturing costs and refined operations support.

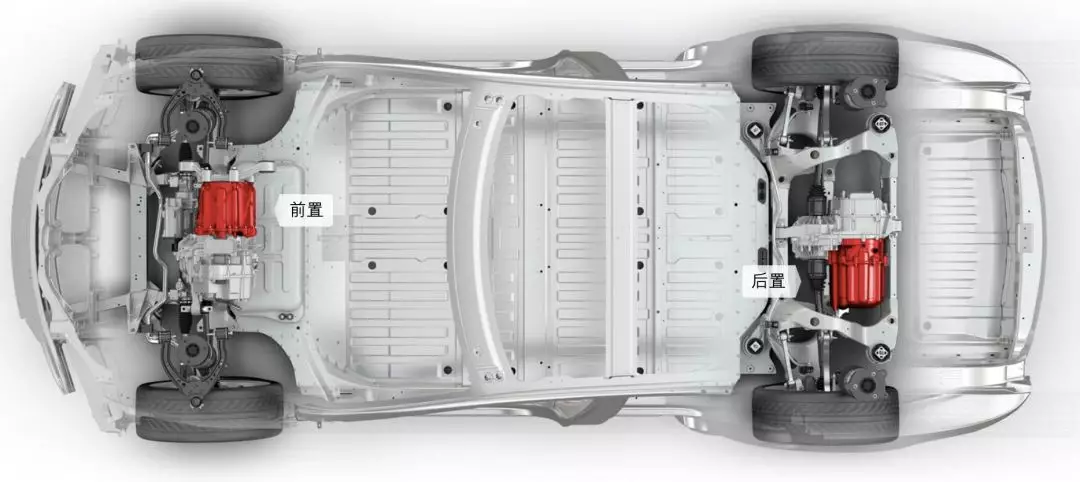

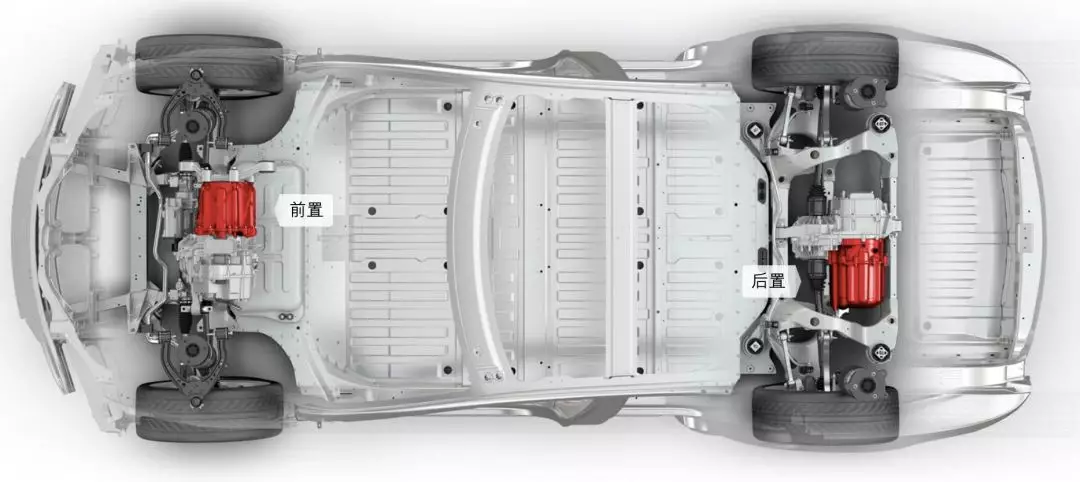

The first is the investment and mastery of core technology research and development. Although the technical difficulty of electric vehicles has been reduced, and the three electric systems can also be purchased, but to get a better and more stable power system, car companies must build their own native platform, so that the battery module The design achieves the best results and increases the energy density of the battery.

Although Dyson ’s car-making dream is broken, the solid-state battery technology developed by Dyson has considerable market potential. Compared with lithium batteries, this battery has better performance in energy density and safety. It must also be thinner, with an energy density of 400 Wh / kg. It is important to know that the energy density of mainstream models in 2019 is only 200 Wh / kg.

There are also a series of core technologies such as ADAS auxiliary systems and automatic driving that are developed synchronously with electric vehicles. It is also a technical field that car companies must pay great attention to and invest in. Take FF as an example. If it were not for hundreds of electric vehicle patents, FF would have almost no investment value. Conversely, if new domestic carmakers want to sell themselves, how much technology will be available for valuation?

Second is the control of the manufacturing cost of automobiles. A major manifestation of the capital intensity of the automotive industry is in the manufacturing process. The investment of an automobile production line starts with tens of billions, and the assembly process of parts and components involved in a production line has several thousand items. At present, several majorOf cross-border car companies are shifting from finding OEM production to self-built production lines.

Once building a factory by yourself, it means changing from a light asset model to a heavy asset model. This will truly enter the superior field of the traditional automobile industry, and it is a brand-new test for the new forces of car manufacturing. A mass-produced car is no longer just a stack of simple parts, but to carefully consider the cost of each link. Under the premise of ensuring performance and safety, the cost is minimized to increase the competitiveness of the market.

The third is the refined operation of the entire car manufacturing and sales industry chain. Let’s look back. In the early days when the new car-making forces began to raise funds madly, whether it was R & D operations, marketing promotion, or even spreading out like a pie, it was not a pain to spend investors’ money. But now that the financing is tightened and the funds are scarce, it is exclaimed that “the money is not enough to burn”, “20 billion is a starting line.” It must be known that Weilai spent 80 million at a press conference in the past.

Tesla, who they studied with, is no longer the bottomless hole of that year looking for money and spending money everywhere. Tesla, which has entered mass production, has achieved precise operations through key steps such as large-scale layoffs, overseas factory construction, establishment of global supply chains, and construction of R & D centers, in order to significantly reduce production costs and focus more on energy, In the production and sales of the lower-priced Model 3, Tesla has completely evolved into a traditional car company, but it is the closest to success.

In the end, some people may have questions, why are we onlookers pointing at these entrepreneurs running on the “most muddy marathon”? Are they not smart enough to understand these common senses? Now that they have run hard enough, they still have to give them more time and opportunities …

Of course, caring and caring are not just words, but consumers need to vote with real money. In the first three years of the capital frenzy, these successful financing car companies can run wilder and try their best. But now, the barbarians outside the door have been killed, and they are still familiar with all the rules of the game in the country. In the future, they will use the same government subsidies to play the same PK with these newborns who are still four or five years old and cannot support their families.

More scary is that the slow-moving global big-name car companies have quietly turned around, and these new electric models with mature craftsmanship, stable quality and gratifying prices have entered the blue ocean.

The wolves are here, leaving us the new forces of cross-border car-making, time and opportunities are really running out.