The lid also improves the use performance, is not easy to spill, and is convenient for consumers to drink drinks without using a straw.

For beverages without pearls and fruits, the direct-drinking cup lid can solve almost all problems, and there is no need to worry about replacing plastic straws.

But for the new tea drinks that are made more and more abundant, “not sucking up” is a fatal blow.

These three options have their own advantages and disadvantages, but they are not perfect. The industry’s top priority is to find a more perfect alternative.

In the second half of the year, there may be disruptive iterations in the straw field

Recently, the leading brands have been working with manufacturers of environmentally friendly materials to make breakthroughs in research and development.

“Brands are more anxious than us. During this period, people come to ask about environmental protection straws.” said Luo Liangshan, founder of Zundao Packaging.

Zundao, who has been doing food packaging, last year and Nai Xue jointly pushed PLA straws. A year ago, they had begun to deploy new materials that are more environmentally friendly and high-temperature resistant. At present, they and Nayuki are working together on upgrading products for environmentally friendly straws.

Luo Liangshan believes that paper straws must not be a long-term solution, and the problems of taste and resistance to foam cannot be completely solved. The future trend in the industry must be to find better alternatives. “We are also looking for directions, and it is expected that there will be a landing in the near future.”

Currently, the environmentally friendly straws they have developed can be divided into two major directions according to their nature:

1. Upgraded PLA straw: high temperature resistant, easy to use but expensive

Using PLA+PBAT (thermoplastic biodegradable plastic) to modify the degradable material, it has broken through the high temperature of 85 ℃ and can keep it from deformation. The straw made of this material can be used for both cold and hot drinks.

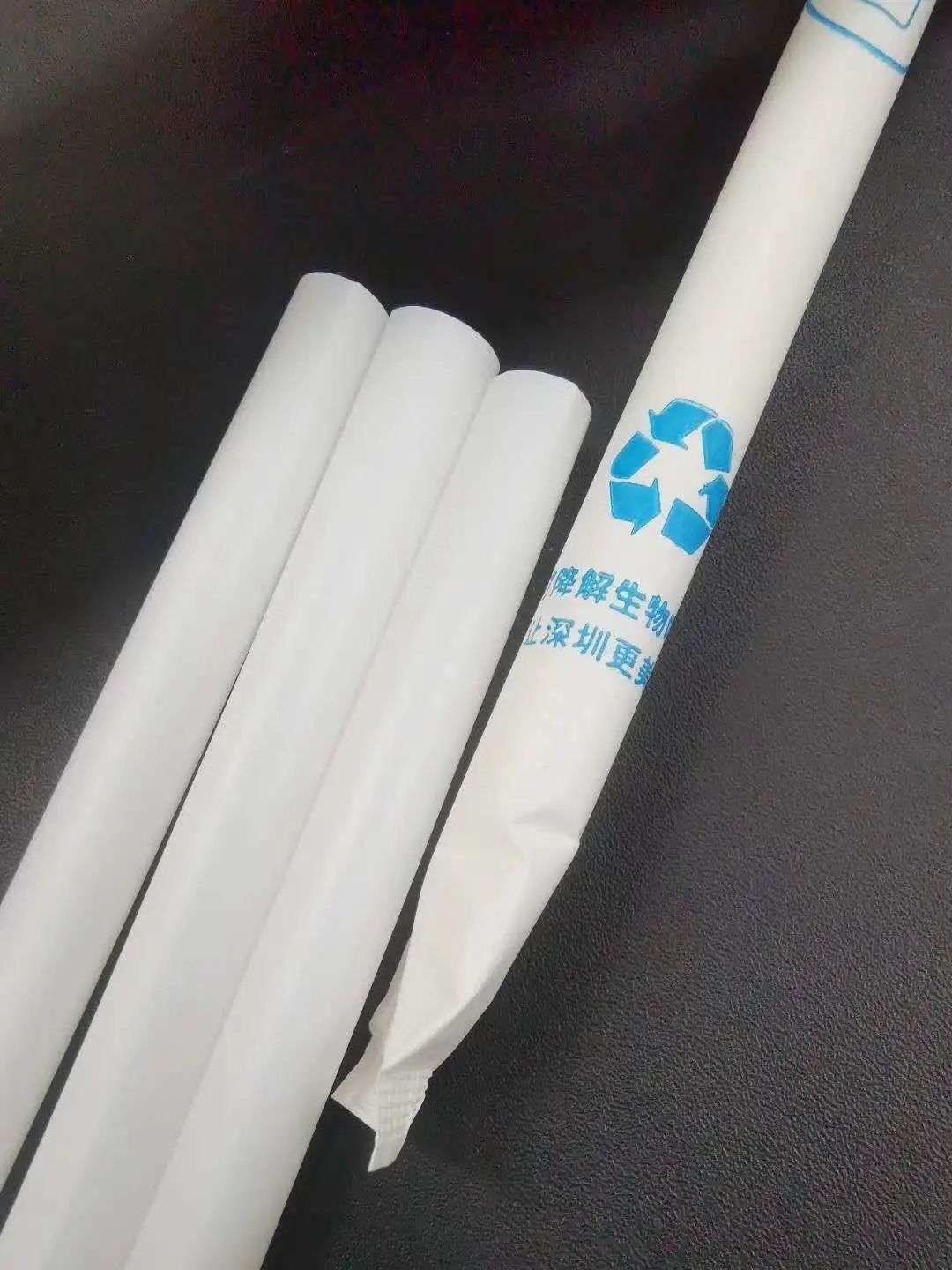

Newly developed PLA fully degradable biological straws

-

This kind of straw has obvious advantages: high temperature resistance, full degradation, can be used at -20℃~85℃, and the conditions required for degradation are relatively low.

-

The shortcomings are also obvious: the cost is high and the cost is high, which puts a certain burden on the store.