Lasertec, a Japanese semiconductor test equipment manufacturer, is continuing to grow with EUV (Extreme Ultraviolet) test equipment, which accounts for the largest share of the world.

Editor’s note: This article is from the micro-channel public number “Nikkei Chinese net” (ID: rijingzhongwenwang), Author: Nikkei Chinese network.

Lasertec, a Japanese semiconductor test equipment manufacturer, is continuing to grow with EUV (Extreme Ultraviolet) test equipment, which accounts for the largest share of the world. Semiconductors produced by extreme ultraviolet lithography machines are expected to be mass-produced, and the demand for test equipment supporting extreme ultraviolet is also expanding. Lasertec focuses on design and development and entrusts most of its production to outsiders. Its “fab-light” advantage has expanded its revenue, and its stock price has more than doubled in one year in 2020.

Lasertec started paying attention to extreme ultraviolet about 20 years ago, when the technology was expected in the semiconductor industry. It was officially set as the focus of operation when the company suffered a loss in the Lehman crisis about 10 years ago. In order to revive performance, President Okabayashi, who took office in July 2009, decided that “semiconductor circuits will continue to be miniaturized, and we will use this to promote future growth” and began to develop a “photomask (using extreme ultraviolet light in the crystal The design drawing when the circuit is fired on the circle) and the test equipment for the “mask blank (the substrate for drawing the circuit)”.

Lasertec has only about 400 employees and is a small-scale semiconductor equipment company. The business model is to strive to develop the largest share of products in niche (niche) areas that are difficult for large companies to reach. In niche areas, it is difficult to predict the future at the start of R&D, so the ability to screen potential businesses is very important.

In the research and development process, each project must first form a small team of elite technical personnel. Technological innovation in the semiconductor industry is rapid, and the main customers in niche areas are limited. Therefore, it is necessary to adopt a flexible and flexible system to meet customer requirements while collecting information. Since R&D is started with a small amount of investment, if the progress is not smooth, the track can be corrected quickly, which is also meaningful in terms of risk management.

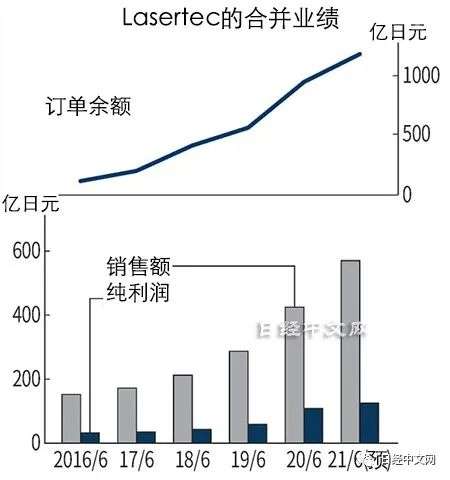

Lasertec’s net profit has increased in the last 3 years