The pure white panel of smart phones may no longer appear in the future.

Editor’s note: This article is from the micro-channel public number “Three Easy Living” (ID: IT-3eLife), Author: Sany bacteria.

With the end of the Spring Festival holiday, the mobile phone industry has also revived. While many brand new products are ready to go, Meizu has also confirmed that it will hold a new product launch conference on March 3 to launch Meizu 18 series flagship models. Before the debut of the new series of phones, Meizu posted on social media a few days ago, “#meizu17# series of 5G dream flagships, the last stand-in for the white front panel.”

At the moment when the Meizu 18 series will be unveiled, the news released by Meizu is obviously implying that the new machine is likely to abandon the white front panel that it has been insisting on starting from the Meizu 15 Ru Kiln White. As for why mobile phone manufacturers are now abandoning white panels, in fact, you can use the explanation given by Smartisan product manager Zhu Haizhou, which is “will lose money.”

It is undoubtedly correct to use economic factors to explain the increasing rarity of white front panels, but “expensive” may not be the whole reason. Throughout the entire development process of mobile phones, in fact, whether white can be used on a large scale has a strong relationship with the changes in the material of the mobile phone itself and consumer preferences.

In the early days, mobile phones were basically constructed of plastic. However, using white on plastic materials was the most costly way. The reason is that white plastic cannot be used to reduce costs by using recycled plastic. In fact, recycled plastic is a material commonly used in the entire industry. It is not only more environmentally friendly, but also can effectively reduce costs. However, in the process of reusing various sources of recycled plastics, it is easy to adhere to dark colors, but the reverse is true. The cost of dyeing it back to white is very high, so using a white body means it needs to be made of new plastic particles.

And for the plastic body, there is a more important problem with the use of white, that is, it is not very resistant to dirt, and it is prone to yellowing. This is because chain polymers in plastics are exposed to ultraviolet rays, infrared rays, and microorganisms under high temperature and oxidizing environments, which will produce many free radicals, and the break of molecular chains will cause changes in appearance. Among them, white plastics The performance is particularly obvious. The most effective way to deal with the yellowing of white plastics on the market is “plastic refurbished yellowing agent”, but it is obviously not suitable for precision electronic devices such as mobile phones with poor sealing.

In the era of metal fuselage, although black is one of the most difficult colors for metal materials, white is not easy at all. The iPhone 4, which started the era of smartphones, was released in June 2010, but the white version of the iPhone 4 did not go on sale until April 2011. The reason why consumers have to wait for nearly a year is allegedly because of process problems. Since human eyes are particularly sensitive to the color difference of white, it is difficult for a white mobile phone to achieve a relative brightness balance during the spraying process, and the final result is that the front and rear panels are yellowish or blueish to different degrees, which is what we often say It’s colder and warmer.

From the perspective of the production process, the white panel is different from the black in terms of printing difficulty and steps, and due to the influence of various external factors, the final printing effect may also be deviated. Medium often needs to go through 3-4 printings, while black only needs 1 time. Friends who like to play with model toys such as Gundam may know that spraying white paint on the body is also an operation that is very technical. Excessive painting will cause paint buildup, which will cover the details of the body, and under-quantity will cause uneven coloring. Therefore, a small amount of times is needed to achieve uniform coloring. In fact, the process of white panels is the same.

What’s more, white is very easy to cast color, and the tolerance is also very difficult. As long as the manufacturing process is slightly unstable, the color cast problem will occur. However, the current mobile phone production is often not a one-shot deal. Different production batches, different environments, and different control standards will lead to a great increase in the difficulty of quality control of white mobile phones. Once a problem occurs, it is easy to appear colorful and white. With a sense of cheapness. According to Apple’s statement that year, the upstream supplier was responsible for the cutting machine for white panels, and could only cut three panels per hour that met the requirements. Such efficiency is obviously horribly low.

So Zhu Haizhou said, “The white panel mobile phone is very difficult, and the process is extremely difficult. From color toning, coating printing to laminating process, tolerance difficulty, yield, etc., each is a challenge.” , In fact, from the era of metal fuselage to now when the glass fuselageA phenomenon that exists in all generations. However, the increase in manufacturing costs can actually be passed on directly to consumers, as long as users pay for it. However, the problem today is that many consumers no longer pay for it.

If the white version of the mobile phone really looks better, even though consumers with sufficient budget will not hesitate to buy such a product to satisfy their desire to show off, after entering the era of full screen, the white mobile phone is obviously not so It looks good, even Apple’s iPhone no longer uses white panels.

In fact, this is because although it is “one white covering a hundred ugliness” for people, for a full-screen mobile phone, it is “a black covering a hundred flaws”. White is to enlarge the visual effect, and black is to shrink. Therefore, for mobile phone manufacturers who want to maximize the visual immersion of the full screen, in addition to improving the craftsmanship to increase the screen-to-body ratio, use a black panel with a black screen. It is also an important means to enhance the unity of the fuselage as much as possible. After all, almost no manufacturers are willing to do things in the full-screen era at the expense of lowering yield and increasing costs, and making their own mobile phone products look wide.

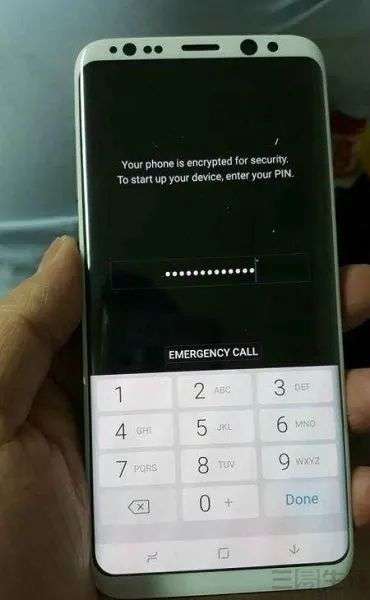

In the era of full screen, the space left for the front sensors of the fuselage, such as the front camera, the earpiece, and the distance sensor, has also become smaller and smaller, and these sensors are all dark-colored, with the white front panel The contrast is obviously extremely obvious. Some netizens have made a rendering of the iPhone X with a white front panel and a white Samsung Galaxy S8 engineering machine. You may wish to experience this style of painting.

Speaking of “color difference contrast”, Black Matrix (BM area), that’s meThe black borders of the screen that we often talk about can also not be ignored. Due to tolerances, even the same models produced on the same assembly line are often unable to achieve absolute alignment. If the screen frame is aligned with the visible edge of the BM area, bright edges will appear around the screen, and the core value of the BM area is to prevent light leakage from the screen. But because the BM area is black, it is naturally easy to integrate with the black front panel, and there will be a very obvious color difference with the white panel when the screen is bright.

So when the white color itself is difficult in the manufacturing process and does not meet the needs of the current full-screen era, Meizu can insist on adopting the white front panel design to this day, in fact, it is already an extremely valuable thing, let alone Said that another Nut mobile phone known for its white body is “cold” now.