Semiconductor industry observation: The Japanese government announced on July 1 that it would strengthen its export management to South Korea. On July 4, it launched “Polymide” and “EUV Resist”. Export restrictions for three hydrogenated materials of hydrogen fluoride.

Editor’s note: This article is from WeChat public account “Semiconductor Industry Watch” (ID: Icbank), author Tang Shanglong.

Source: This article was translated from the public sector semiconductor industry observation (ID: icbank) from “jbpress”, author Tang Shanglong, technical management consultant, director of the Japan Micro-Processing Institute, thank you.

The Japanese government announced on July 1 that it would strengthen its export management to South Korea. On July 4, it launched “Polymide”, “EUV Resist” and “Hydrogen Fluoride”. “Export restrictions on three semiconductor materials. According to the export restrictions, the Ministry of Economy, Trade and Industry’s review of the export of the above three materials will take up to three months.

At the end of June, the G20 was held in Osaka. The export restriction was a “sneak attack” on Korean companies! The “sneak attack” reminds people of the “Japan attack on Pearl Harbor” during the Second World War.

Semiconductor material stock is only about 1 month old Samsung Electronics and SK Hynix strongly urged Japanese companies to provide “EUV Resist” and “hydrogen fluoride” for three months from July 1st to March 3rd, unable to cope with this unreasonable Japanese material. The manufacturer was once in chaos.

And, finally, on August 2, the Japanese cabinet government decided to remove South Korea from the “white list”! To this end, after August 28, almost all product names will be subject to a separate review by the Ministry of Economy, Trade and Industry. (Japan Economic News, August 3)

To this end, while the South Korean government is preparing to file a complaint with the World Trade Organization (WTO), the president of the National University of Hong Kong also said that “we will take decisive measures against Japan’s unfair economic retaliation.” ! Hong Nanji’s economic deputy and planning finance minister also said: “Korea will also remove Japan from the list of ‘ preferential countries’ and strengthen managementExport daily!

It can be said that Japan and South Korea have already fallen into the “comprehensive war” stage! What damage will the Japanese-Korean war bring to the two countries? In addition, what impact will it have on electronic equipment and communication equipment? This article will analyze short-term impacts and long-term impacts.

In addition, the author does not comment on the politics of Japan and South Korea, and only analyzes the impact on technology, products, and industries caused by export restrictions imposed by the Japanese and Korean governments.

Short-term impact~~Semiconductor factory stops the action

After July 4th, “Polymide”, “EUV Resist” and “Hydrogen Fluoride” have become export restrictions! As mentioned at the beginning of the article, the materials inventory of Samsung Electronics and other manufacturers is only about one month, so the semiconductor factory may stop the operation this month! The effects are shown in Table 1 below.

Table 1: The impact of restrictions imposed by the Japanese government on Korean exports. (Form from: jbpress)

If the inventory of “Polymide” is zero, LG Electronics will not be able to produce organic EL TVs. Moreover, if “EUV Resist” is not in stock, Samsung Electronics will not be able to produce 7nm process Logic semiconductors. Therefore, the production of Samsung’s latest smartphone “GALAXY” will also be Delay. For the cutting-edge DRAM in mass production, there is almost no impact, and the development of next-generation DRAM will be frustrated!

Moreover, the most influential material is “hydrogen fluoride”! If the “hydrogen fluoride” of the syrup for cleaning semiconductors is zero, storage semiconductors such as logic semiconductors, DRAMs, and NANDs, and organic EL panels (Panel) will not be produced!

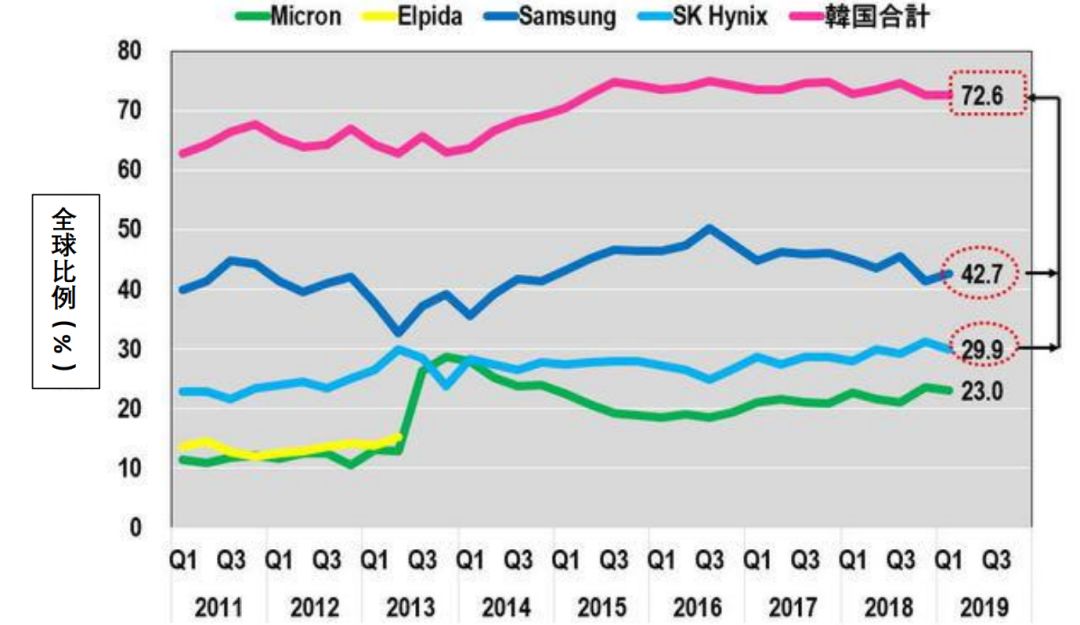

In particular, Samsung Electronics and SK Hynix have a global DRAM share of 72.6%, NAND’s global share of 39.4%, and DRAM and NAND production only stop for 1-2 months, global electronic devices The communications equipment industry will be in great confusion.

as aboveAs mentioned in the article, the impact of stopping the production of DRAM (Impact) is amazing! If it does not ship for 2 months, there will be 230 million smartphones (more than 1.4 billion), 43 million computers (260 million), 25 million tablets, 2,785 SSDs (16,715,715) 10,000), 2.17 million servers (13 million units), and various digital home appliances (the total number of shipments in 2018 in brackets).

About the SSD (Solid State Drive) here, in a nutshell, recent SSDs have adopted NAND, controller, and DRAM. Therefore, if the DRAM cannot be produced, the SSD cannot be produced, and thus the PC and the server cannot be produced.

American companies will also be “victimized”

As mentioned above, if there is no “hydrogen fluoride”, the semiconductor factory will be shut down! If DRAM and NAND cannot be produced, various electronic devices and communication devices that need to store semiconductors will be affected.

Before this, if the semiconductor factory stops the production, Silicon Wafer, Resist other than EUV (for i-line, KrF, KrF Dry, ArF soak solution) The business of CMP polishing liquid (Slurry), chemicals other than hydrogen fluoride, various gases for dry etching (CVD) and CVD will also disappear.

Moreover, when DRAM and NAND shipments are stopped, smartphone manufacturers such as Apple and Huawei, PCs such as HP and Dell in the US, and server vendors (Server Maker), Amazon, Microsoft, Google and other cloud vendors (Cloud Maker) The business will also be affected.

In short, only Samsung Electronics and SK Hynix’s hydrogen fluoride in the library is zero, which can have a great impact on the global electronic equipment and communication equipment!

Cannot find a replacement for hydrogen fluoride in a short time

Some people in the current society say that it is not enough to replace hydrogen fluoride in Japan with hydrogen fluoride from Taiwan, China, Russia and other real estates. However, the replacement is not so easy! The following description will be made.

Semiconductor production has 500~1,000 processes, using hydrogen fluoride cleaning, wafer etching (Wafer Etching) process accounted for about 10%. For example, there are 1,000 processes in which about 100 hydrogen fluorides are used. Moreover, the dilution ratio of the hydrogen fluoride in each of the steps is different, and an additive such as a surface (interface) active agent is also added.

In a nutshell, the use of hydrogen fluoride is the most appropriate ratio that is precisely calculated in every step of the semiconductor, the so-called “Recipe”. Moreover, only hydrogen fluoride manufacturers are aware of this “secret recipe.” In short, semiconductor manufacturers such as Samsung Electronics understand the effect of “secret”, but the content of “secret” uses hydrogen fluoride as “Black Box”.

Therefore, if non-Japanese-made hydrogen fluoride is used, semiconductor manufacturers such as Samsung must start with the material manufacturer’s most suitable “secret recipe”. However, this is not achieved by a simple “Beaker experiment”, which needs to be verified with the yield of the semiconductor to get the most suitable ratio.

It takes 2-3 months to make a semiconductor on 25 silicon wafers of the same lot number (Lot). Even if it is expedited to produce, it takes several weeks, and the experiment is repeated to develop the most suitable “secret recipe” for 100 processes. And this “development” takes 1 year under the Best Case and usually takes 2-3 years.

If the production of DRAM and NAND is stopped during this period, the development and production of global electronic equipment and communication equipment will also stop. Its economic losses cannot be measured.

Loss to production equipment manufacturers

If it is impossible to purchase hydrogen fluoride from Japan and the “secret” of non-Japanese hydrogen fluoride cannot be developed, Samsung Electronics and SK Hynix will have to stop investing in equipment. Beginning in the second half of this year (2019), the sluggishness of storage semiconductors began to improve. It seems that there are signs of restarting investment. However, according to the current situation, most equipment manufacturers that receive orders should use 100 units. The order was cancelled.

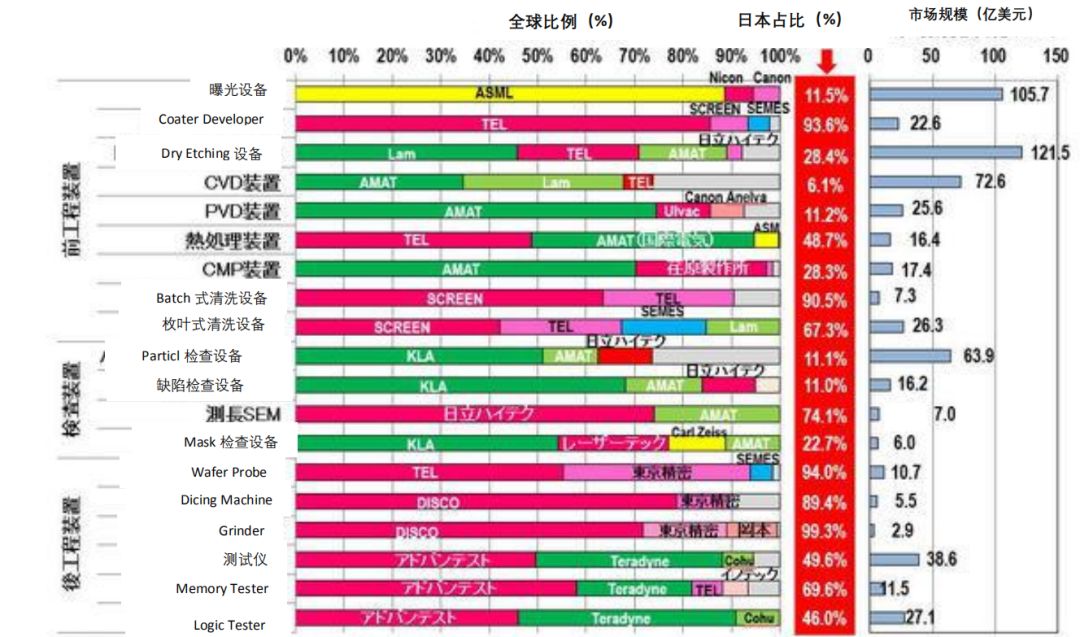

As shown in Figure 1, the company’s pre-semiconductor process, inspection process, and post-process are the proportion of companies and market size. Many devices are divided by Japan (red), the United States (green), and Europe (yellow). If equipment investment is delayed and equipment investment is delayed, all equipment manufacturers will be “injured”.

Figure 1 Percentage of companies in semiconductor manufacturing equipment (Japan’s share) & market size (2018). Red & Pink:Japan;Green:United States;Yellow:Europe;Blue:Korea. (Image by:This form was compiled by the author based on data from Nomura Securities.)

Japan’s global share is as follows: Coater Developer (93.6%), heat treatment equipment (48.7%), Batch type (90.5%) and leaf cleaning equipment (ie, single cleaning equipment, 67.3%), testing Long electron microscope (SEM, 74.1%), Probe (94.0%), Dicing Machine (89.4%), Grinder (99.3%), tester (49.6%) (the number in parentheses is the proportion of Japanese equipment sales in 2018) . These Japanese companies may be subject to cancellation orders!

In addition, many parts of equipment manufactured in the United States and Europe are made in Japan, and these Japanese companies may also be affected.

Medium and long-term impact~~Japan’s Big Business will not exist in Korea

The Korean government announced on July 3 that it plans to provide a budget of 1 trillion won (about 5.58 billion yuan) per year to support the localization of semiconductor materials and equipment. (Japan Economic News, July 4)

In addition, the South Korean government held a temporary cabinet meeting on August 3, and decided to immediately implement the budget of 272.3 billion won (about 1.44 billion yuan) for the Japanese government to remove South Korea from the “white list.” South Korea predicts that imports from Japan will stagnate, so we will accelerate the implementation of diversified imports and localization of parts and materials imported from Japan. (Japan Economic News, August 3)

Samsung Electronics, SK Hynix, etc. are considering removing the Japanese-made materials that become “Bottle Neck” as quickly as possible.Imports of equipment, parts, devices, etc.

For example, in the production equipment shown in Figure 1, South Korea should gradually change the procurement of equipment. Coater Developer’s procurement from Tokyo Electronics to Korea’s SEMES, Dry Etching equipment from TEL to the US Lam Research (Lam) and AMAT (Applied Materials Company) in the United States, heat treatment equipment from TEL to AMAT, CMP from Sugawara to AMAT, cleaning equipment from SCREEN and TEL to SEMES, length measurement SEM from Hitachi High Technologize to AMAT, Probe by Tokyo Electronics and Tokyo Precision turned to SEMES, and the tester was transferred from Advantest to Teradyne in the United States.

In addition, Korea should consider developing Coater Developer, Batch Cleaning Equipment, Probe, Dicing Machine, Grinder, etc., which are dominated by Japan.

The result is that, five years later, Silicon Wafer made in Japan, including all photoresists for EUV (Resist), polishing solution for CMP (Slurry), including hydrogen fluoride All of the potions inside, all other gas materials used for Dry Etching and CVD, all production equipment, its parts and equipment, etc., are likely to no longer exist in Korea’s Big Business.

South Korea may not be able to sell DRAM and SSD to Japan

On the one hand, Korean semiconductor manufacturers depend on many Japanese-made materials and equipment; on the other hand, Japanese electronic equipment and communication equipment depend on Korean storage semiconductors! Moreover, it is said that the Korean media also reported on the opinions of relevant government officials: “If the Korean government believes that storage semiconductors can be used as a weapon for South Korea’s counterattack, it can also be classified as a target for Korean exports.” (Japan Economic News, August 3)

If the Korean government restricts the export of DRAM to Japan, Japanese electronics manufacturers will be helpless! South Korea’s Samsung Electronics and SK Hynix account for 72.6% of the world’s total (Figure 2). Second, there is not even a DRAM manufacturer in Japan!

Figure 2: The proportion of each business in each quarter of DRAM. (Image by: I created this image based on DRAM eXchange, IHS, Trend Focus data.)

Smartphones, PCs, SSDs, servers, various digital home appliances, and even supercomputers can’t be produced without DRAM! The only object in Japan that can import DRAM may be Micro Technologize in the United States, but it should not be able to fill the amount of DRAM produced in Korea, and the development of cutting-edge DRAM is far behind Samsung Electronics.

Moreover, as mentioned above, since the recent SSDs also use DRAM, the NAND manufacturer Kioxia (formerly Toshiba Memory Semiconductor) will not be able to produce SSDs.

In addition, South Korea’s SSD shipments account for 43.3% of the world. Among them, Samsung Electronics has an absolute advantage of 33.4%, and its SSD has the advantages of large capacity, fast speed and excellent performance.

Figure 3: Shipments of each company in each quarter of the SSD. (Image courtesy of: I created this image based on Storage Newsletter, Trend Focus; Business Wire data.)

If the Korean government sets such a high-performance SSD as an export restriction, many Japanese electronics manufacturers should be in trouble.