“Quality is a matter for all employees, and quality is our belief.”

Editor’s note: This article is from WeChat public account ” 42 garage “(ID: iCar123) , author Chris Zheng .

The public relations of Weilai may be one of the hardest groups in the automotive industry.

In 2019, I have strengthened this view.

Far from saying that last month’s ES8 recall and sales are weak, it is a troublesome. When Wei Lai slammed in 2018, the voice of the public opinion was endless. In 2019, Wei Lai struggled in the troubles of interlocking, and public opinion was even more unrelenting: Is Wei Lai finished?

On August 15th, 42HOW came to the Jianghuai Weilai factory in Hefei, Anhui Province to find out.

The tragedy of 837 vehicles

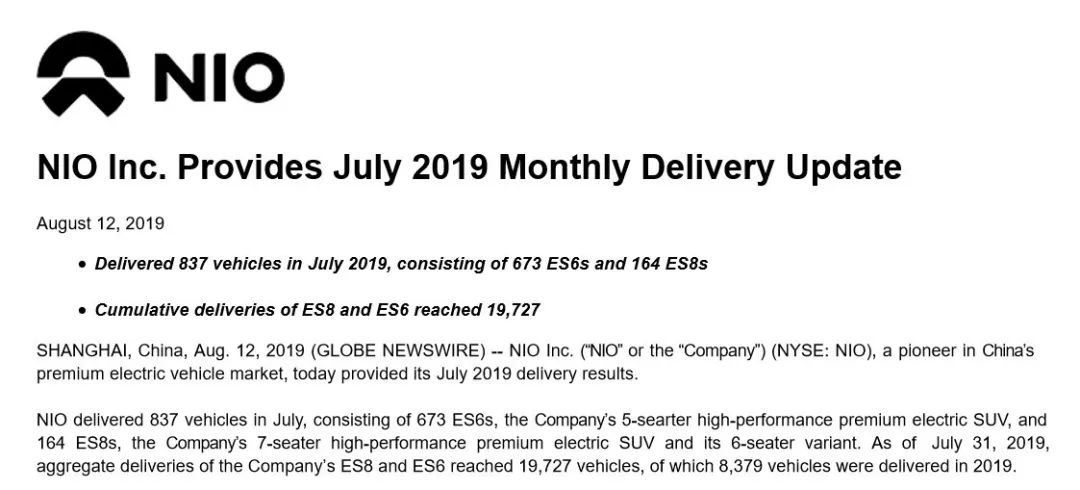

Open Baidu Yisou, Weilai sold 1502 vehicles in July 2019, including 1066 ES6 and 436 ES8. However, on August 12th, Weilai announced its sales in July 2019. We have delivered a total of 837 units, including 673 ES6s and 164 ES8s. The third source shows that in July, the Weilai ES6 sold 660 units and the ES8 sold 153 units.

What is going on?

In fact, all three of these data are correct, from the production of the association, the actual delivery volume announced by Weilai, and the upper limit of China Automobile Federation.

In terms of manufacturing, Wei Lai, like Tesla and Porsche, adopts the OTD (Order-To-Delivery) order-based production system, and all the models put into production are in one-to-one correspondence with existing orders. Therefore, the sales of the association will be logical in terms of output, but at the same time, due to the relationship between logistics, delivery and licensing, the actual sales delivered to the users will tend to be lower than the sales volume, and the above-mentioned risk will be lower than the actual delivery.

The following discussion, we take the actual delivery volume published by Wei to the standard.

837 cars/month, what is the level of this achievement? It was down 37% year-on-year and down 37.5% from the previous month.

The same ring double drop, the public opinion detonated: the original ES6 + ES8 product matrix achieves the effect of 1+1>2, how 1+1< 1?

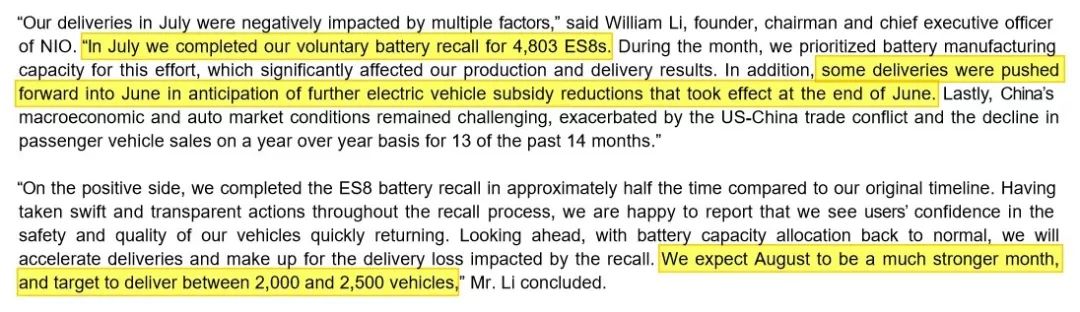

Shen Feng, Vice President of Quality and Chairman of Quality Management Committee, explained this issue in the Jianghuai Weilai factory: there are two basic factors, one is subsidy, and the other is the impact of ES8 recall on production capacity. .

“This recall is unlucky, but we may have created a record for this industry. Nearly 5,000 cars have been less than a month from the time they announced their recall and re-delivery.”

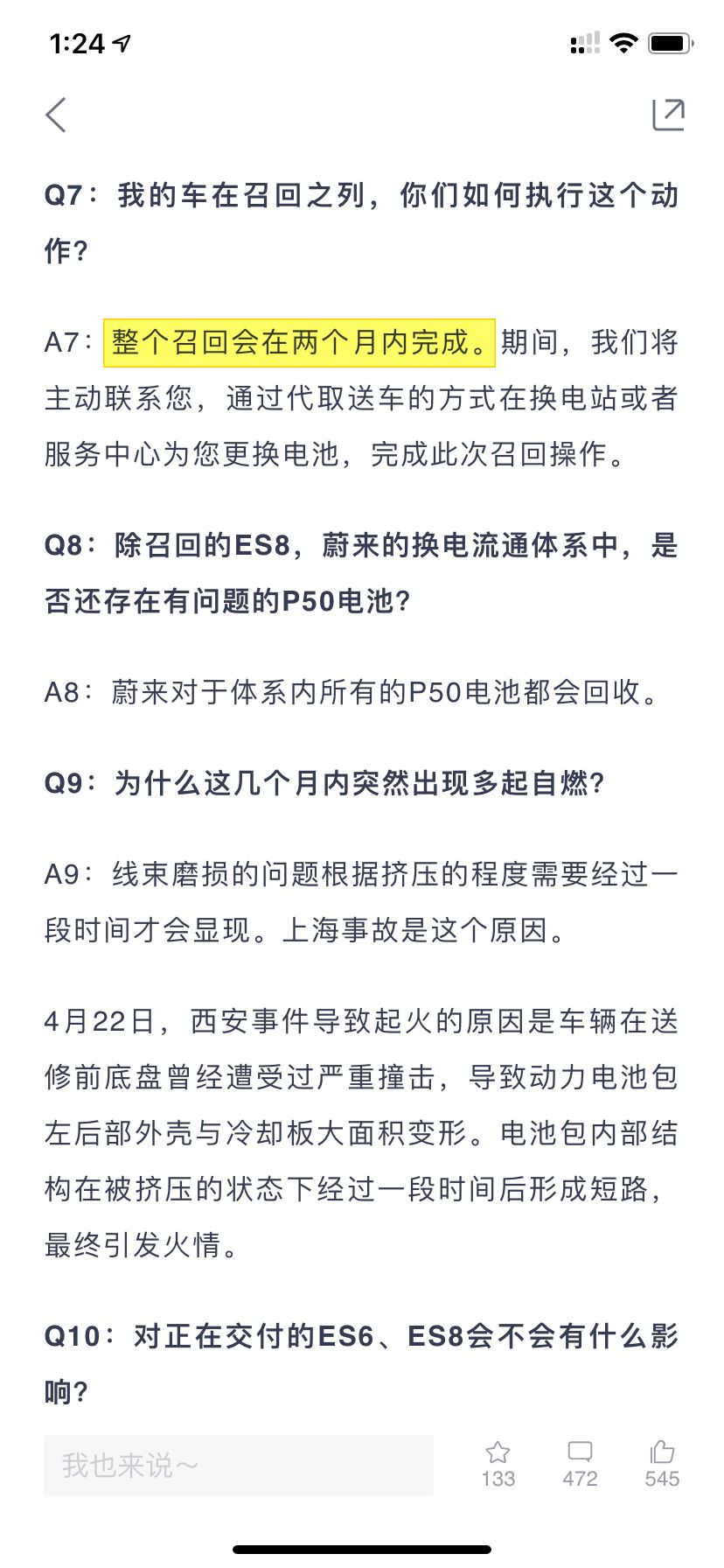

On June 27th, Wei Lai issued the “Statement on Partial ES8 Recalls”. In the “Declaration”, Wei mentioned that 4,803 ES8s “the entire recall will be completed within two months.”

Information published at the New Energy Vehicle Consumption Forum.

This means that in the past month, Weilai’s total vehicle delivery was 837 units, but the battery pack delivery was actually 837 + 4,803 = 5640.

What is the concept? It grew by 324% year-on-year and 321% quarter-on-quarter. The demand for such a large battery in a short period of time has no pressure, and the supply of power batteries in the Ningde era is under pressure.

Before the Ningde eraExplain that the Weilai battery module is customized and the production line is only suitable for Weilai products. Ningde can pull up the production capacity of the special production line within one month, and cooperate with Wei to complete all the recall work. The first place in the power battery industry is not sitting in the white.

But at the same time, The battery supply for new car orders in July is inevitably squeezed.

In addition to this, the 2019 New Energy Vehicle Subsidy New Policy, which was implemented on June 25, also overdrafted sales in July to some extent, and concentrated some of its demand to early release in June.

This is in line with the quarterly sales record of Tesla’s US home in Q18 in 2018. The Q1 sales in 2019 dropped sharply in the same world. The same story – from January 2019, the US new energy vehicle subsidy quota has fallen by 50%.

In fact, whether it is a recall or subsidies, Li Bin It was explained in the Weilai July delivery announcement. In addition to these, Li Bin also talked about something else: As the battery supply returned to normal, Weilai’s August sales guidance will reach a record 2,000-2,500 units.

“Light effort is not enough, but rely on professionalism and system”

Initiating a recall of nearly 5,000 vehicles, is there any problem with the quality of Weilai? Faced with such doubts, Shen Feng, vice president of quality and chairman of the Quality Management Committee, spent a day explaining the work done by Wei Lai.

Before introducing Weilai, let me introduce Shen Feng.

When joining Weilai at the end of 2017, Volkswagen’s understanding of Shen Feng is one of the words: Volvo’s Polestar Global CTO and President of China, and President of Volvo China R&D. But for Wei Lai, Shen Feng’s brilliant resume in Ford was even more important.

Ford interiorImplement Six Sigma management strategy. In the automotive industry, Six Sigma is not a new concept, it is a set of techniques to improve the management of enterprise quality processes. According to the degree of learning and mastery, employees will be divided into yellow belt, green belt, black belt and black belt master. In general, only 1% of employees will be trained as black belts, and the team of Black Belt Masters will only be 1/10 of the size of the Black Belt.

Shen Feng has been a senior black belt master at Ford, and has done global R&D, procurement, supplier management and production quality management.

After joining Volvo, Shen Feng participated in Volvo China’s R&D, manufacturing, quality, procurement, IT and other departments.

At the end of 2017, Shen Feng joined Weilai as the chairman of the Weilai Quality Management Committee and began to build the quality system of this young company.

Closer to home, Shen Feng is a leading DFSS (Design for Six Sigma) leader who has led more than 100 Six Sigma projects. He said a word when introducing the Weilai quality system.

Not only design for fuction, but also design for reliability, manufacturing, cost.

In addition to design features, design reliability, manufacturability, and cost.

This is a principle mentioned by Shen Feng: A car is good, and the development stage of the previous period has been defined a lot. So it is very important to pay attention to the quality of the previous development.

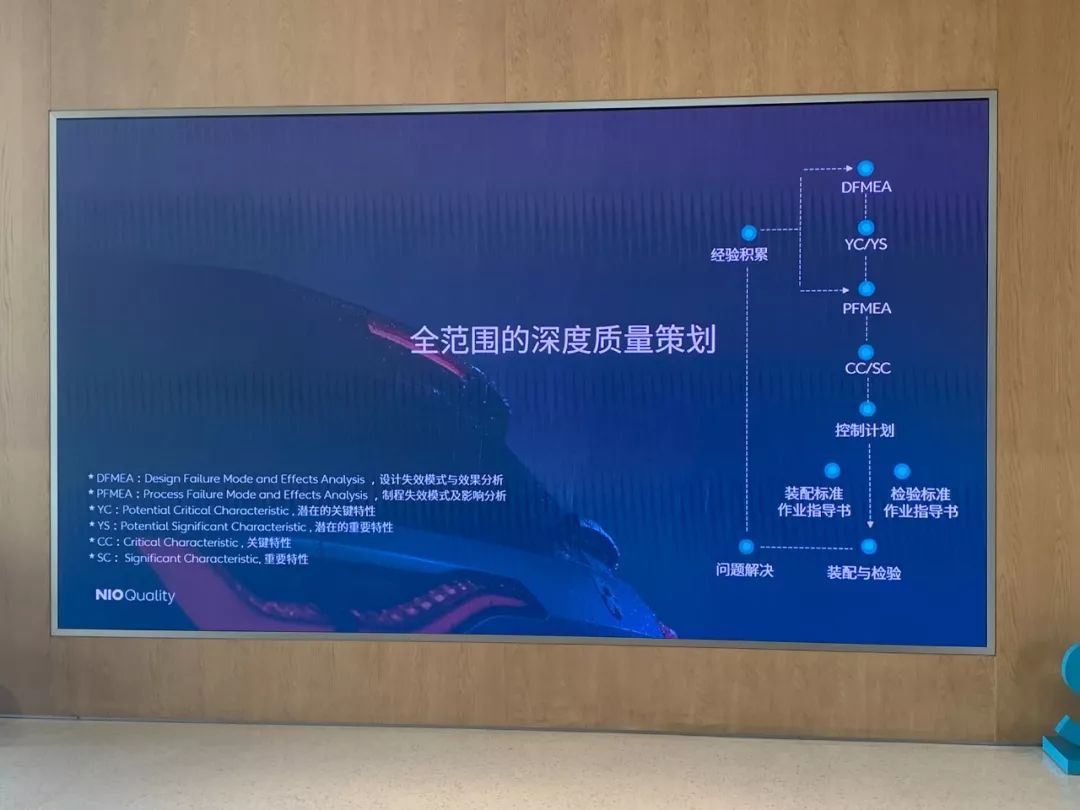

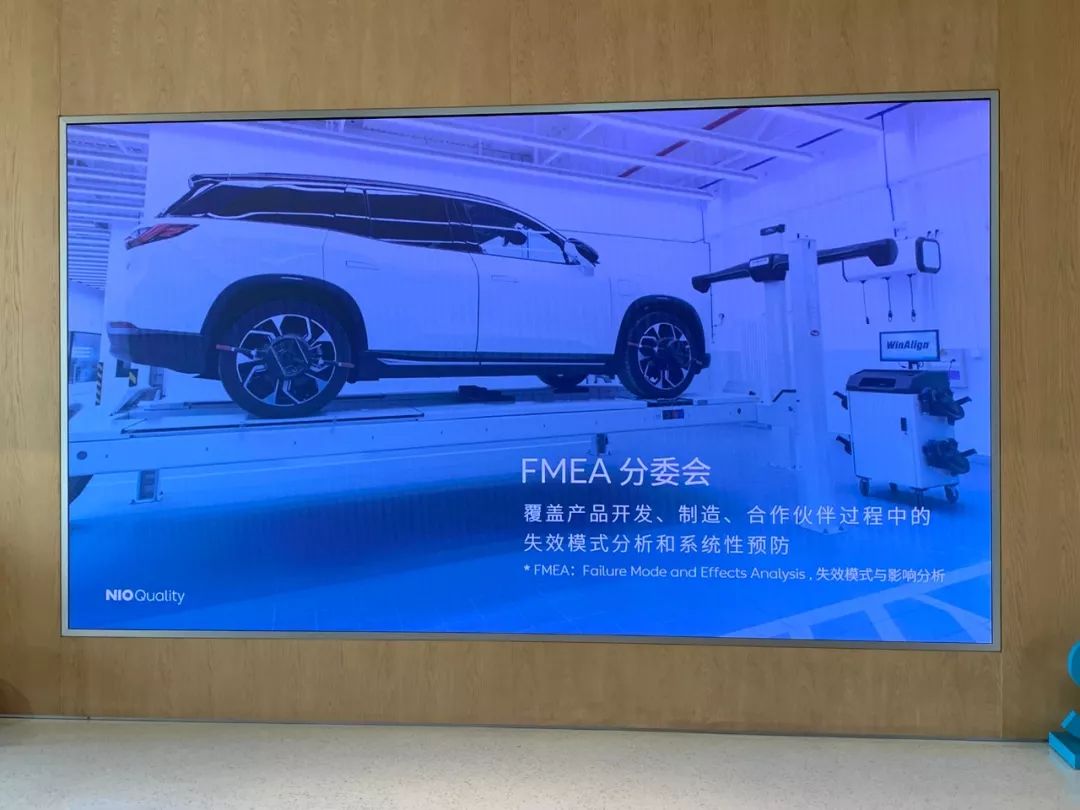

In terms of organizational structure, Shen Feng led the establishment of the FMEA Committee (covering CFMEA, DFMEA, PFMEA) and the Safety Committee (covering functional, mechanical, collision, battery, network, high voltage, chemical 7 safety areas), by focusing on the quality of the previous design, Strengthen early identification and prevention of risks to ensure product safety and reliability in the later stages.

Besides, because before In Ford and Volvo’s cross-business experience, Shen Feng is responsible for the company Enterprise, mass production, after-sales, power management, electric powertrain, software, design, vehicle engineering, supplier, manufacturing, logistics Quality management of all segmented businesses such as XPT .

A new car, from the beginning of the project, to the real delivery to the user, the quality team will take several years to control each link.

In view of the discipline and technical complexity involved in the automotive industry, 0 engineering changes are the safest and lowest probability of failure, and Weilai’s quality management is very complex.

First of all, as mentioned above, Weilai adopts the OTD order scheduling system, and the rich selection of packages can form more than 200,000 optional combinations, which brings great challenges to production management. .

Secondly, the difference between Weilai and the century-old stores in traditional car companies is that due to the lack of research and development and the rapid iteration of the genetic factors, Weilai will have very frequent engineering changes. During the Volvo China period, Shen Feng participated in the work of the Volvo S80 handed over to Changan Ford. However, after he came to Weilai, he found that the engineering-level foundry model is not feasible in Weilai-Jianghuai.

Shen Feng said that OEMs like the Volvo S80 turnkey solution need to meet three conditions:The product is fully mature and will not make any changes; R&D system is mature;The OEM experience is mature.

These three conditions are not available in Weilai & Jianghuai.

After joining Weilai for a few months, Shen Feng realized the problem of foundry. In April 2018, Shen Feng led the coordination of Weilai Jianghuai and became the first responsible person of the Weilai factory. Under his rule, the head of the Weilai factory was responsible for the director of the factory and the Jianghuai factory.Start very good synergy. In Shen Feng’s words, “Two people work very well together and behave like a person.”