The asset-light science policy has deprived the United States of its advantage in the long run.

The Translation Bureau is a subordinate translation team, focusing on technology, business, workplace, life and other fields, focusing on introducing new foreign technologies, new perspectives, and new trends.

Editor’s note: From a technical point of view, semiconductors are an important general technology that plays an important role in almost all supply chains. As the birthplace of semiconductors, the United States has been at the forefront of this field for a long time, but has gradually lost its manufacturing advantage in the last decade or two. How did the United States get to where it is today? What kind of policies will be adopted in the future to regain the advantage? Employ America, an American think tank that studies labor and economic policies, has combed through the history of semiconductors. It believes that the United States needs to be held responsible for shifting from a support-focused industrial policy to a cost-reduction-focused scientific policy, and that it needs to return to an expanded industrial policy. Come to regain American superiority. From this, we can also think about our own countermeasures. The original text was published on Medium with the title: A Brief History of Semiconductors: How The US Cut Costs and Lost the Leading Edge. The length of the relationship is too long. We will publish it in two parts. This is the second part.

Key points:

1990s: The United States replaced industrial policy with science policy

2000s: The Internet bubble burst, and the semiconductor industry’s returns were diminishing

2010s: “Fabless” companies, R&D and offshore outsourcing become a trend

Today: America may return to industrial policy

1990s: Science policy, not industrial policy

In the 1980s, the industry faced changes in technology and the competitive environment. The 1990s witnessed the climax of the new “science policy” in the United States. In the 1990s, the U.S. did not return to industrial policy (whether it was the kind of policy adopted by the U.S. in the past or the practice more influenced by the Japanese Ministry of International Trade and Industry), but regarded the introduction of “scientific policy” as the government’sA new paradigm for action in the field of conductor manufacturing. The focus of the scientific policy is to promote public-private cooperation with individual companies, allow industry R&D and academic R&D to be more closely integrated, ensure the breadth of research capabilities, and form an industry structure that can support innovative companies with asset-light operations.

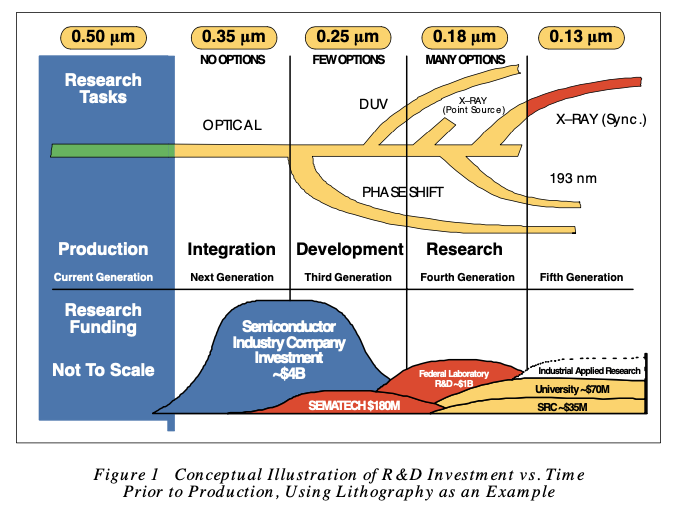

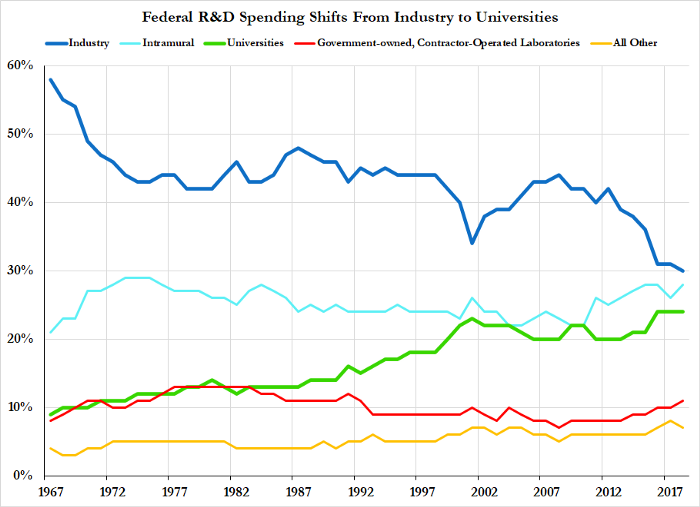

The goal of the policy has also changed from establishing a robust and competitive ecosystem with a strong supply chain to establishing public and private institutions to coordinate research institutions, fabless design companies, equipment suppliers, and large “champion companies” The complex relationship between. In this way, no company needs to invest more than absolutely necessary in R&D-so as to maintain global cost competitiveness-and the government can avoid large-scale investment expenditures. The following table comes from the 1994 “National Semiconductor Technology Roadmap” formulated by the American Semiconductor Industry Association, from which we can see the strategy behind the scientific policy:

Source: American Semiconductor Industry Association

The central theme of this arrangement of “science policy” is non-redundancy in the narrow sense. Early industrial policies focused on redundancy and duplication, with the goal of bringing innovation to every link of the supply chain as soon as possible. Both large and small companies manage their own production, and second-source contracts ensure that feasible processes are quickly spread to the corporate ecosystem. Although the early industrial policy strategy greatly accelerated the pace of innovation and ensured that the entire supply chain was not affected by the company’s individual failures, it did mean that there would be a lot of repeated investment. And although this method helps to promote the adoption of process improvement, the static maximization of shareholder value determines that this duplication is economically wasteful.

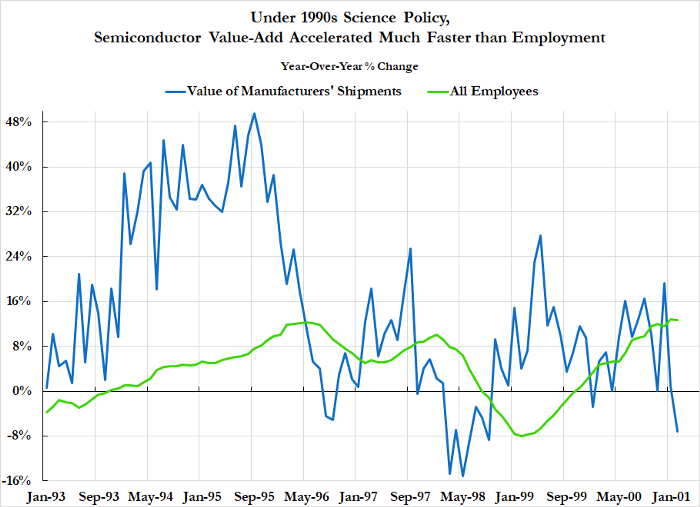

Industrial policies of the past few decades have promoted large-scale employment (this is the core driving force of innovation), while the “science policy” of the 1990s avoided the use of this for efficiency and simplicity. Practice. Workers often change companies, and learning by doing is the main way to innovate. In fact, research on “non-trade interdependence” in economic geography has been developed to a certain extent, partly to explain the importance of the mixing of large numbers of semiconductor industry workers to rapid industry innovation. In a new competitive environment, although the concentration of a large number of workers in one place is the key to many developments, in this new competitive environment, this is considered a waste. Labor is an important part of unit cost. Enterprises believe that if they can reduce the scale strategically, they canTo restore global competitiveness.

Source: US Bureau of Labor Statistics, US Census Bureau, author’s calculations

In the early days of semiconductors, relatively price-insensitive government contracts accounted for a large portion of total sales, and this inefficiency was seen as the cost of innovation. With the entry of foreign competitors, and the cost-conscious commercial market has become the main purchaser of semiconductors, the replication of this ability seems like a pure cost center, but it does not benefit many companies. Concerns about profitability mean ensuring that there is as little repetitive work as possible in order to control costs in a price-sensitive and competitive environment. This created a problem of collective action. Cutting expenditures became a concern for every company, but this further deteriorated the innovation capabilities of American companies.

In the 1990s, the U.S. government did not choose industrial policy, but chose a lower-cost scientific policy plan. Ideally, a “scientific policy” would allow the government to coordinate the ambivalence of companies that want to save costs without further lagging behind in technology. However, in order to keep pace with the times, the U.S. government must also be strict in economy. In this way, it will not be possible to provide the large-scale financial support needed for industrial policy to succeed in the new competitive environment.

On the contrary, the government intends to spend a lot of money less, and is trying to open up a new division of labor, hoping that all participants can cut costs in pursuit of profit without sacrificing the technological frontier. To this end, it subsidizes the research and development work of academic research laboratories on the one hand, and on the other hand supports industry groups to transform research results into commercial capabilities. This further reduces the value of the company’s own R&D investment to some extent, because technological advancement creates a competitive advantage with minimal knowledge. This structure forms such a division of labor, each company or institution is responsible for a separate part of a seemingly separable innovation process, which is not a corporate ecosystem with overlapping supply chains. At the same time, looser trade policies and better transportation capabilities make it more economical for leading companies to “outsource”, which is a strategy with the lightest assets. The goal is to reduce the redundancy of the entire system by solving a collective action problem, thereby regaining the technological frontier in the most economical way for the public and private sectors.

In the short term, this strategy worked! In the late 1990s, as domestic investments in semiconductors and broader technologies in the United States advanced by leaps and bounds, the United States successfully restored its technological superiority.Potential. This industry is able to innovate while maintaining international competitiveness without the need for large-scale financial support from domestic industrial policies. Most individual companies focus their research and development on the next two nodes of the production process, while longer-term research is organized by academic researchers funded by the government. Then industry groups stepped in to transform academic research into commercial actors, and the cost of repetitive labor in the R&D and production process was greatly eliminated. Large-scale centralized research laboratories have become hollowed out, and the supply chain has become narrower, focusing only on the research needs of a few core companies.

2000s: Internet bubble and diminishing returns

However, the recent success of this strategy has been achieved at the expense of long-term costs. The redundancy of labor and capital helps to ensure that the company can quickly make internal process improvements, while also training the next generation of engineers and technicians. Although this duplication may be “superfluous” from the perspective of static maximization of shareholder returns within a certain period, it is essential to ensure that innovation is maintained in the long-term. “Eliminate redundancy” and “increase vulnerability” are two sides of the same coin.

Eat corn seeds, and the strategy of underinvesting in order to extract profitability and competitiveness can only work once. In the long run, insufficient investment in labor and capital will eventually be reflected in the balance sheet or innovation capabilities, or both. For now, the United States is likely to lose its leading edge in cutting-edge design and has already lost most of its leading edge in manufacturing (to TSMC TSMC). Allocating part of the investment process to each company may make the company’s balance sheet look more robust, but due to continued underinvestment, the entire industry becomes more vulnerable. Decades of minimizing labor costs have reduced the number of skilled technicians and engineers, and decades of insufficient investment in production capacity have hampered the ability of American companies to cope with current shortages.

The current problems in this industry are the natural result of the long-term trend of science policy, even though it was so successful in the late 1990s and early 2000s. Academic laboratories are engaged in long-term research, huge “champion companies”, and asset-light “fabless” innovators, focusing on the merger and vertical integration of this pattern, and promote the formation of a shaky competitive ecosystem.

Because these champion companies occupy a large share of the competitive landscape, their R&D priorities and intermediate input requirements set conditions for the entire industry. Major buyers like Intel can explicitly or implicitly use their relative monopoly power to narrowly build a supply chain around their own needs. When broader economic needs change (which have actually changed since the outbreak began), these fragile supply chains can easily go wrong. This vulnerability is forIt should be the result of chain optimization, but this optimization is aimed at short-term profitability and eliminating redundancy, rather than the needs of the entire economy.

The design foundry model meets the ceiling

Whether intentionally or unintentionally, champion companies will shape the path of technological development around their financial needs and plans. Therefore, the combination of academic laboratory research and development, private enterprise tax optimization, and unit cost minimization policies have resulted in a heavy reliance on technological paths. At the same time, from a technical point of view, these champion companies are “too big to fail”: If these companies miss the process improvement, the lack of domestic competitors of the same size means that the entire industry will miss this opportunity for improvement. . In a sense, the United States delegates the entire technology policy to private actors.

2010s: “Fabless” companies, R&D and offshore outsourcing

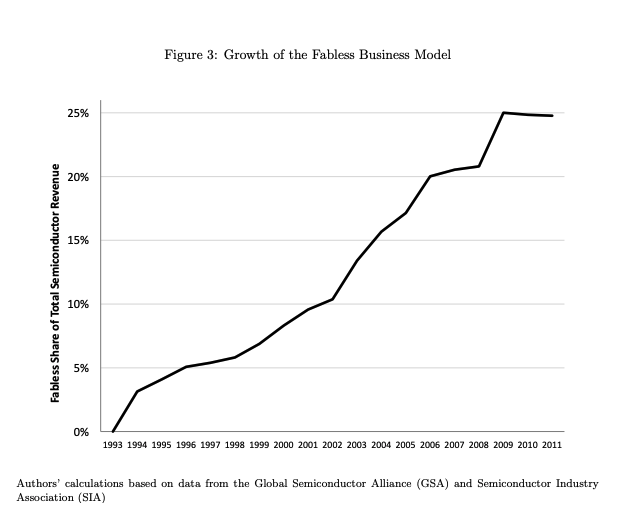

From R&D to production, weird inconsistencies and feedback loops also began to appear. The key to scientific policy strategy is to separate intellectual property innovation and production process innovation analytically and economically. In layman’s terms, policy focuses on research, design, and ideas, rather than implementation, production, and investment. The rise of “fabless companies” that take advantage of the process improvements of foreign manufacturing plants is a direct result of this strategy.

However, prioritizing R&D may slow down the pace of innovation. Just subsidizing R&D is no different from encouraging offshore outsourcing: the policy rewards the development of intellectual property, not the ownership of tangible assets. The problem is that process improvement comes from the implementation of new technologies contained in new physical assets. “Learning by doing” is a key part of technological innovation. Excellent engineers hope to innovate in every step of the production process at every link of the supply chain. The offshoring and outsourcing of cutting-edge design introduces a black box around the process, resulting in problems such as uneconomic benefits that cannot be corrected. Focusing only on research and development will offshore the development of these process improvements, causing domestic producers to not have enough food, and at the same time preventing the labor force from forming new skills.

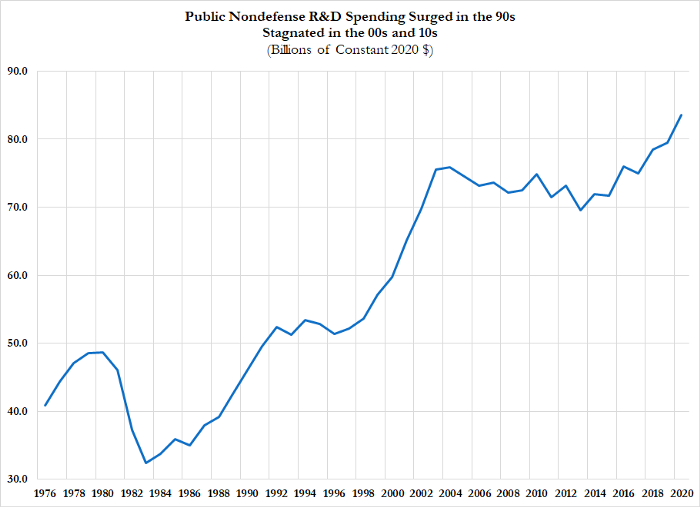

Source: American Association for the Advancement of Science, author’s calculations

Considering that academic research has deviated from the path of commercialization and locked in a specific innovation paradigm, this constraint is particularly obvious. Given that academic research usually revolves around issues unrelated to current production, it is not surprising that sometimes those studies fail to provide insights into alternative applications of existing technologies or alternative process-driven innovation paths. Since science policy puts this group of people in charge of the long-term innovation strategy of the entire industry, this blind spot cannot be ignored. In fact, the failure of Moore’s Law and the transformation of many applications towards unique designs for heterogeneous chips are a good indication that innovation often implies multiple paths for technological development at any time.

Source: American Association for the Advancement of Science, author’s calculations

The failure to invest in production capacity and job opportunities for decades has created a situation where American companies need to rely heavily on external manufacturing plants. The current plan for TSMC to invest and set up factories in the United States is just to use money to temporarily get out of the predicament, but it cannot reduce our dependence on leading-edge single-source suppliers. On the contrary, we should review the history of the industrial policy of early semiconductor manufacturing, regain the forefront of technology, and promote innovation in every aspect of the supply chain.

Today: Policy Connotation and Strategy

Now that the United States is facing a back-end semiconductor shortage and a decline in innovation capabilities, policymakers are considering serious intervention measures. Although it may be too late to solve the current shortage problem, it is time to prevent the next shortage problem. Both parties have expressed support for increasing infrastructure spending. It is imperative to rebuild better after the epidemic. Coupled with anxiety about semiconductor procurement, these factors have prompted policy makers to believe that it is now ambitious. The time is right for reform. It should be clear from the above that the history of semiconductor industry policy has provided many lessons for how to best create high employment, technological innovation, and a robust supply chain.

History shows that science policy is a necessary supplement to industrial policy, but science policy alone is not enough. Coordinating research and development is a necessary part of any solution, but it is hardly the whole solution. forTo master process improvements and ensure that the workforce has sufficient skills to deal with the technological frontier, the industry needs to see continued capacity expansion. However, as we have shown before, private companies are clearly reluctant to make uncertain investments in a low-demand environment. Industrial policies that combine government procurement, financing guarantees, and direct financing are the only way to provide the industry with sufficient liquidity to ensure the rapid growth of production capacity, so as to keep the industry at the forefront of technology. At the same time, the government also has the financial ability to ensure that American companies have the ability to produce commercial semiconductors on the back side for reasons of domestic security and supply chain flexibility. In the long run, the practice of outsourcing industrial policy to shareholders to maximize shareholders does not work.

It is also important to realize that the strong demand of the overall economy and the resulting shortage in the labor market, especially in the semiconductor manufacturing labor market, are critical to the success of these policies. A strong government-led investment expansion can create good job opportunities for people with different experience and skill levels, thereby creating a highly skilled workforce, and also providing a lot of learning by doing Opportunities to drive meaningful process improvements. In industries with high skill requirements and high capital intensiveness, labor is almost like another form of capital goods, which can bring obvious dividends to investment. However, in the absence of sufficient employment opportunities, these specialized skills will disappear as workers move to other industries. However, this is not to say that just improving the skills of the workforce is enough: if you develop a training plan without creating the necessary jobs and investment, you will quickly become self-defeating.

Some people may cringe at the scale required to fund industrial policies in key industries such as semiconductors. This is a huge market, with high price tags, and a modern manufacturing plant can easily cost billions of dollars. However, semiconductors are a key universal technology entering almost every supply chain. Large-scale industrial policies can prevent it from becoming a bottleneck and drag down economic growth. At the same time, it can also establish a strong domestic supply chain for national security needs. Compared with the initial investment in semiconductor technology, the cost of returning to industrial policy is much higher, but the return is greater. As part of the US$4 trillion infrastructure or cross-party supply chain bill, revitalizing the back-end and frontier industries and restoring to a strong competitive ecosystem is a good investment that should not be missed.

The policy objective is simple: formulate an expanded industrial policy toolkit, foster innovation, form a domestic labor market that is in short supply, and maintain critical supply chain infrastructure. The semiconductor industry is an ideal starting point for understanding these policy tools due to the large amount of investment and jobs required. Rebuilding a strong innovation environment will also help the United States return to the forefront of technology, creating jobs and investment, which will bring dividends for many years to come. Semiconductors play a vital role in the modern industrial economy, and their technical routes are veryImportant, short-term profitability cannot be used as a guide. The government has the opportunity and responsibility to use industrial policies to stop this situation before the next shortage occurs.

Translator: boxi