Remember the last year’s industrial robot arm that can self-assemble Ikea Stefan chairs? This arm can be precisely adjusted according to the force sensor and assembled in 20 minutes.

▲ Image from: Nanyang Technological University

The robot was developed by Eureka Robotics, a startup company of Nanyang Technological University in Singapore. Recently, the company launched a new one called ArchimeThe mechanical arm of des) can handle precision optical lenses like a human hand.

According to Associate Professor Fan Guangqiang, the founder of Eureka Robotics, Archimedes is a six-axis robot. The motion of the robot arm is controlled by an artificial intelligence-based algorithm. In addition to controlling the force, it can also mimic the flexibility of human fingers. And visual acuity.

The robot arm that assembled IKEA furniture last year relied on a 3D camera to identify objects with a precision of only a few millimeters, while Archimedes has increased the recognition accuracy to tens of micrometers, and the error of placing items is controlled at 0.1 mm. The blessing of the AI algorithm.

“Archimede” identifies the size of the lens, sorts the lenses into different molds, and waits for the coating. However, Archimedes’ speed is not faster than that of humans. It still takes hours to complete such work, but it can free employees from this kind of mechanical work and focus on other work.

In the past, the processing of optical lenses such as glasses and camera lenses required manual sorting. Different types of lenses were taken out from the jig and placed in a mold for processing. However, in the process of manual sorting, from time to time, falling and scratching may occur, and the robot is expected to reduce the loss caused by the processing.

▲ Image from: Market Expert24

It is reported that “Archimede” is suitable for precision optical instruments including glasses, cameras, medical imaging, etc. This robot can further improve the production process through AI analysis based on the data collected at work.

Mr. Fan Guangqiang revealed that Archimedes has attracted the interest of some precision instrument manufacturers in the United States, Japan and Singapore. A laser optical manufacturer from the United States has ordered this robot, the first “Akimi De” will be delivered within a few weeks.

Eureka Robotics The next step is to get Archimedes to do more different types of work, such as machine parts such as drill bit drilling and tap tapping.

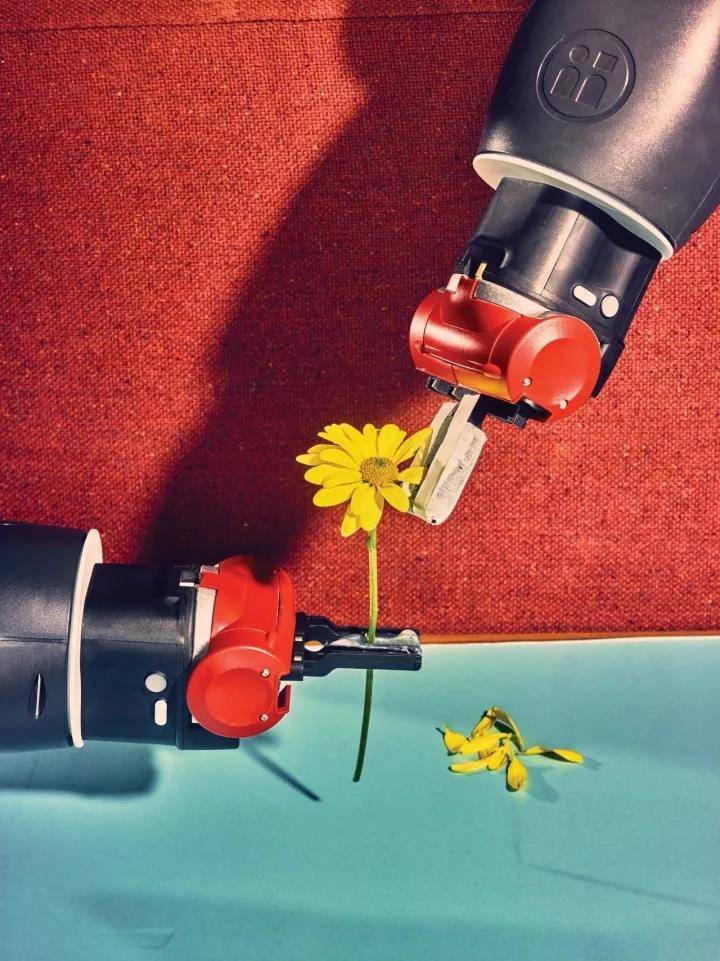

▲ Image from: New Yorker

In fact, in the past many industrial manufacturing lines, there have been many industrial robots, such as the robotic arms that screw the screws on the automobile production line, but let the robots perceive different objects like human hands, according to different shapes, sizes and It is still not easy for texture objects to take different strengths.

▲ Figure from medium.com

But machine learning has greatly accelerated the progress of robots, such as a raspberry machine developed by the University of Plymouth, UK Robocrop, It has been able to apply pressure without damaging the fruit, even more efficiently than humans.

The last year’s non-profit artificial intelligence organization a robotic arm developed by OpenAI makes it easy to complete delicate fingertips such as rotating cubes. Operation, behind the AI model of deep reinforcement learning training.

As the robot’s “finger” becomes more flexible, many labor-intensive repetitive tasks may be replaced by machines, and the future of automation is not far from us.

The title map and some of the maps are from: Nanyang Technological University