Beijing time last night, Dyson issued a notice announcing the suspension of the car, because “the project is not commercially viable”, which means that Dyson realized that the car project invested by his own family could not make money.

The internal letter of Dyson founder James Dyson said: “This is not a product failure, nor a team failure.” In fact, Dyson has successfully developed a prototype car, the product is very consistent with Dyson’s philosophy, but Unfortunately, it is not commercially viable.

The internal letter also revealed several key messages. Dyson tried to sell the car project, but suffered from no buyer, so he had to stop the project. The next Dyson will focus on the solid-state battery and vision system. , robotics, machine learning, AI related technology.

After cutting off the car project, Dyson made a clear statement about the team members’ stay. The department has a total of 523 employees, 498 of whom are in the UK. Dyson will work hard to find other positions within the company for the vast majority of people. Their home appliance business has enough vacancies; if Dyson cannot properly arrange or have employees do not want to Staying at the company, Dyson will respect and support their choices.

In September 2017, it was also an internal mail. The 70-year-old British richest man, James Dyson, announced the formal entry into the car industry with several design sketches. The goal was to launch a new car in 2020. The plan shows that Dyson will invest 2 billion pounds, half of which will be used for battery research and development.

A variety of signs show that making a car is definitely not a temporary intention of Dyson. From the side, how deep is the hard work of the past, how hard it is to give up today.

The story is based on a long-standing dream of James Dyson. Unlike many “speculators” flocked by the electric car industry, Dyson may seem more like an “environmentalist.”

James Dyson said that he has worked hard to solve the problem of automobile exhaust since 1990, but no one paid attention to his research field at the time. He also wrote academic reports on diesel exhaust emissions and mouse deaths, but no one took care of him.

In the development of hair dryers, fans and air purifiers, Dyson has a deep technical accumulation in motors, energy storage systems, fluid dynamics and HVAC systems, James Dyson believes that electric vehicles Let Dyson “finally have the opportunity to integrate all the technologies into the same product, without filtering the exhaust from the exhaust pipe. Today we have the ability to solve it from the source.”

The previous article we mentioned is that the 523 team has actually started construction since 2013. Dyson has successively dug the former Rolls Royce, Land Rover, Bentley, Tesla, British luxury sports car manufacturer Aston. Martin, and many other car companies in research and development, technical personnel.

The global production R&D director is Ian Minards, former engineering director of Aston Martin, and its automotive business director, Andy Gawthorpe, previously served as director of strategy and planning for Jaguar Land Rover, while John Stamford, engineering director, is the Mercedes AMG UK F1 engine. Departmental electronic supervisor.

In April of this year, Roland Kruger, former president of Infiniti, was also dug into Dyson and became the head of the automotive project.

In October 2015, Dyson spent $90 million to acquire Sakiti3, a US solid-state battery company. Compared with ternary lithium batteries, solid-state batteries have better performance in terms of energy density, battery form, safety, etc., and were once considered the best choice for next-generation power batteries.

In March 2016, the British government accidentally leaked Dyson’s “Building Plan.” At that time, the British government decided in the infrastructure construction plan to provide DST’s battery technology development with a subsidy of 16 million pounds. The original explanation clearly stated that “the use of new batteries to develop electric vehicles” was subsequently quickly revised. .

In March 2017, Dyson announced a $2.5 billion joint venture with Google and Facebook to transform the former Royal Air Force Base in Hullavington, England into a research institute that will focus on AI, robotics and other cutting-edge technologies. Includes battery and vision system. More importantly, the Dyson prototype will also be prototyped and engineered at the base.

The battery is the best in the world, but today’s new cars are almost as focused on the independent research and development of batteries as Dyson. Most of them choose to buy the mature batteries of the suppliers for packaging. Among them, there is no shortage of players who buy a chassis, buy designs, and fight for a car in a short time.

James Dyson once said in an interview with the British Guardian: “The Dyson prototype has not yet been built, and the chassis is not ready, everything starts with a draft.”

From 0 to 1, make a qualified mass production electric car within two years. Although many new cars claim to be able to do today, I am afraid that Dyson is not convinced. Interestingly, the former are mostly Internet companies that are “half-way” and the latter are technology companies that have accumulated in motors and aerodynamics.

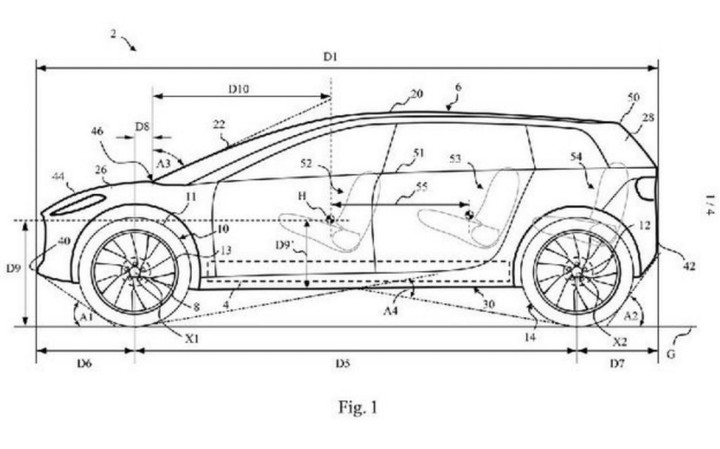

Dyson, which was drawn from the draft, finally released the first draft of the vehicle in May this year. This is considered to be one of the few publicly available product information since the disclosure of the Dyson Auto Project.

From the drawing, this is obviously an SUV model with three rows of seats. The car is about 5 meters long and the car is 1.65 meters high. It is lower than many SUVs, and the wheelbase is awful 3.3 meters. The extremely inclined front wind direction wind resistance compromises, and the whole vehicle looks biased towards the MPV.

Dyson Motors insists on “Dyson Design, Dyson Manufacturing, Dyson Sales”. They plan to build the model in Singapore. The plant will be completed in 2020 and the mass production will be postponed to 2021. Chosen in Singapore, Dyson hopes to use Singapore as a bridgehead to radiate the entire Asian market, especially China.

Know that nearly half of Dyson’s income comes from China. Presumably, many people have heard of it, and now Dyson’s headquarters has also moved from the UK to Singapore. However, most of the plans to establish a car factory in Singapore are abortion.

The Financial Times once commented on Dyson’s car, “If you succeed, you can redefine the Dyson brand; if it fails, it will consume a lot of resources and may even cause the brand to fall.”

In the face of this “gamble”, Dyson finally chose to give up. Although £2 billion is not a big deal for James Dyson and the Dyson Empire he founded, it’s important to know that the late-stage investment is far more than that.

The founder of Weilai Li Bin has a famous saying that 20 billion yuan has just been a ticket for making a car. Then, 2 billion pounds plus the £16 million supported by the British government, Dyson still needs more capital.

In addition, Dyson insists on “doing everything”, chassis research and development, vehicle design, battery, and motor have to come by themselves. The investment required can be imagined, especially the cost of solid-state battery research and development.