The fearless ship sailed 305 days later.

Editor’s note: This article is from the WeChat public account “Garage #42″” ID: iCar123), author of six or three.

November 7th, 8th, The door of the Tesla Shanghai factory was opened to the outside world for the first time. The 42nd garage was the first invited media to come to Tesla’s super factory in Shanghai. In addition to the super factory built in 10 months, A test drive experience of more than 100 km was performed on the domestic Model 3.

This article will be divided into two parts, the factory and the vehicle. If you are concerned about the changes in the domestic Model 3, you can look directly at the second half.

slide to the right Sheet

Let us first review the construction of this legend:

On July 10, 2018, Tesla signed a memorandum of cooperation with the Shanghai Municipal Government to build a wholly owned electric vehicle manufacturing plant Gigafactory 3 in Shanghai.

On October 17, 2018, Tesla announced that it had acquired a piece of 860,000 square meters of land for the construction of the Gigafactory 3.

December 2018On the 6th, the land leveling work was completed and construction will begin soon.

On January 7, 2019, Elon Musk visited China to participate in the groundbreaking ceremony. The Tesla Shanghai factory officially broke ground.

On April 3, 2019, the main framework of the Tesla Shanghai plant began construction.

On May 20, 2019, the Tesla Shanghai factory began to take shape and began internal construction.

On June 16, 2019, production equipment was installed inside the factory.

On July 24, 2019, Tesla’s second-quarter earnings report first announced the internal image of the Tesla Shanghai factory, and a large number of manufacturing equipment has been installed.

On August 20, 2019, the infrastructure project of Tesla Shanghai Plant entered the final stage and obtained the first comprehensive acceptance certificate.

On August 26, 2019, the interior body-in-white picture was first exposed.

On September 19, 2019, the Tesla Shanghai factory was fully inspected and approved.

On October 17, 2019, the Tesla Shanghai plant was approved to begin production of Model 3.

Behind the speed of construction, in addition to the indispensable government support, there is experience from Gigafactory 1 and Tesla’s flat management system.

Construction experience from Gigafactory 1

Gigafactory 1 was originally defined as a world-leading battery production equipment that can be replicated, expanded, and rapidly iterated. All the knowledge gained during product development can be shared with the Giga 3 plant construction team. Half of the expenditures are spent on factories with the same capacity specifications.

Flat management system

At the same time that the Tesla Shanghai plant was put into production, SAIC Volkswagen designed a 300,000-year-old MEB pure electric plant to announce trial production. What is curious is that, apart from the unpredictable construction speed, what is the differentiated kernel of the Tesla factory compared to the industry?

The core competitiveness of the Tesla Shanghai plant remains the result of Elon Musk’s extremely flat organizational structure and a fast iterative culture.The difference in execution efficiency.

A subtle detail is that Zhu Xiaoyu, the president of Tesla Greater China and the director of the Shanghai factory, does not have a separate office in the Shanghai factory. A small office area contains the highest level from the factory to the first All the functions of the line make it easy for all front-line “major” issues to reach the top level, discuss decisions, and implement the entire process within 24 hours.

So what is the problem of “not significant”? When the efficiency of the execution conflicts with the power chain that is uploaded, Tesla’s answer is that efficiency is absolutely a priority.

Either front-line employee can initiate communication at any time, across departments and levels, including direct mailing to Zhu Xiaotong and, if necessary, to Elon Musk.

This is a magical company that has been established for 15 years and still maintains the Day 1 mentality. It is about to start a close-knit battle with the industry giant Volkswagen Group, which has strong R&D, manufacturing and supply chain management capabilities.

The speed of the Tesla factory in everyone’s eyes may be attributed to the green light of the government. Of course, this is essential, but behind this Indispensable Shanghai The construction team and the Tesla staff worked day and night, and under the combined efforts of these three parties, the “Dreadnought Ship” can sail on time!

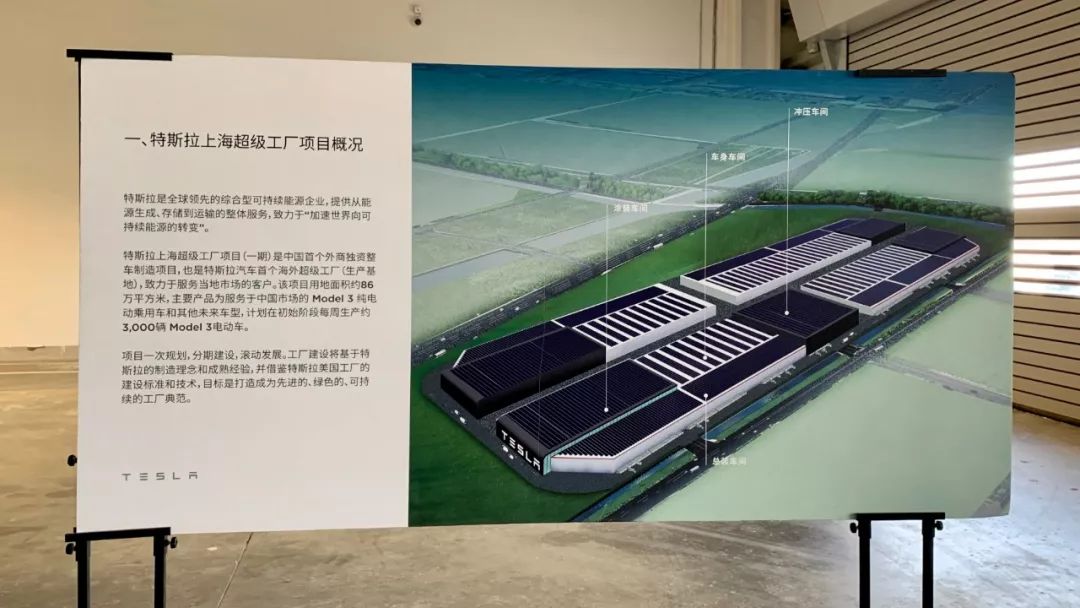

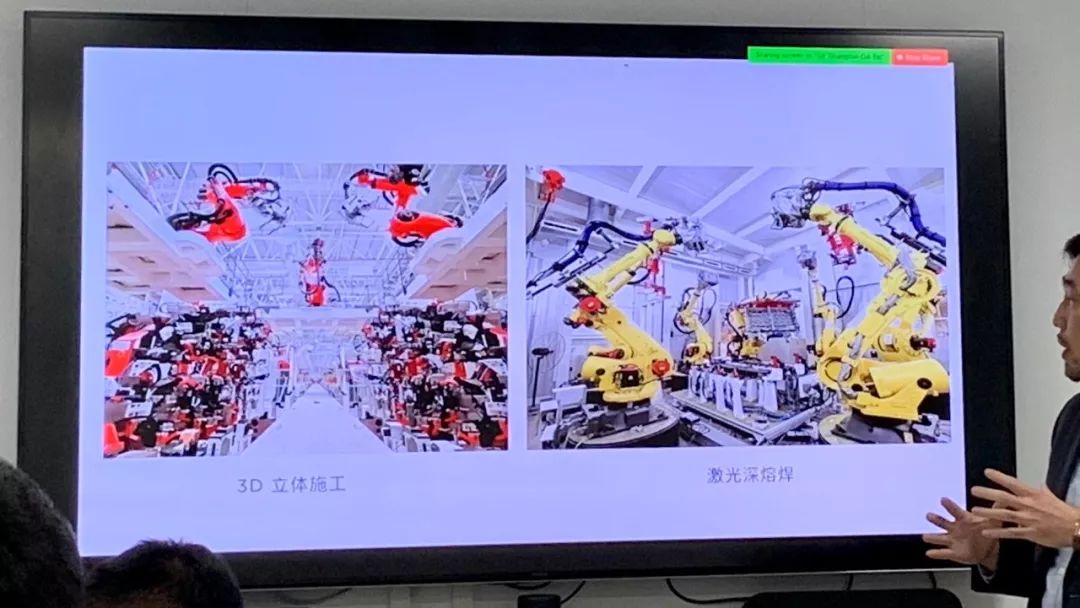

Next, let’s take a look at the internal situation of the factory. Because the factory has not been completely built, it is not open to the public, so we will give you a brief introduction through the official PPT.

The first phase of the Tesla Shanghai Super Factory is planned to be built at a capacity of 150,000 vehicles per year. This is only one quarter of the Gigafactory 3 and the capacity of the entire Gigafactory 3 can reach 500,000 per year. (The picture below shows the early diagram, and the specific plan has been adjusted).

Two worth mentioning details:

First, the welding production line of the Tesla factory can have left, right, and up, and three robots work at the same time. Compared with the two robots, the NC software of the robot arm is more difficult to coordinate. But the efficiency of production can be further improved.

Domestic Model 3 offline Has there been any change?

Before I saw the domestic version of Model 3, my heart was worried about it except for the excitement. I hope that the Model 3 made in China can reach more users at a lower price and let more people feel it. What is an intelligent car, what is a car that can grow, and let more people change their perception and perception of traditional cars. However, I am worried that the mechanical quality of the vehicle will change after being made in China.

Fortunately, my worry is superfluous, it is still the familiar Model 3.

-

About work

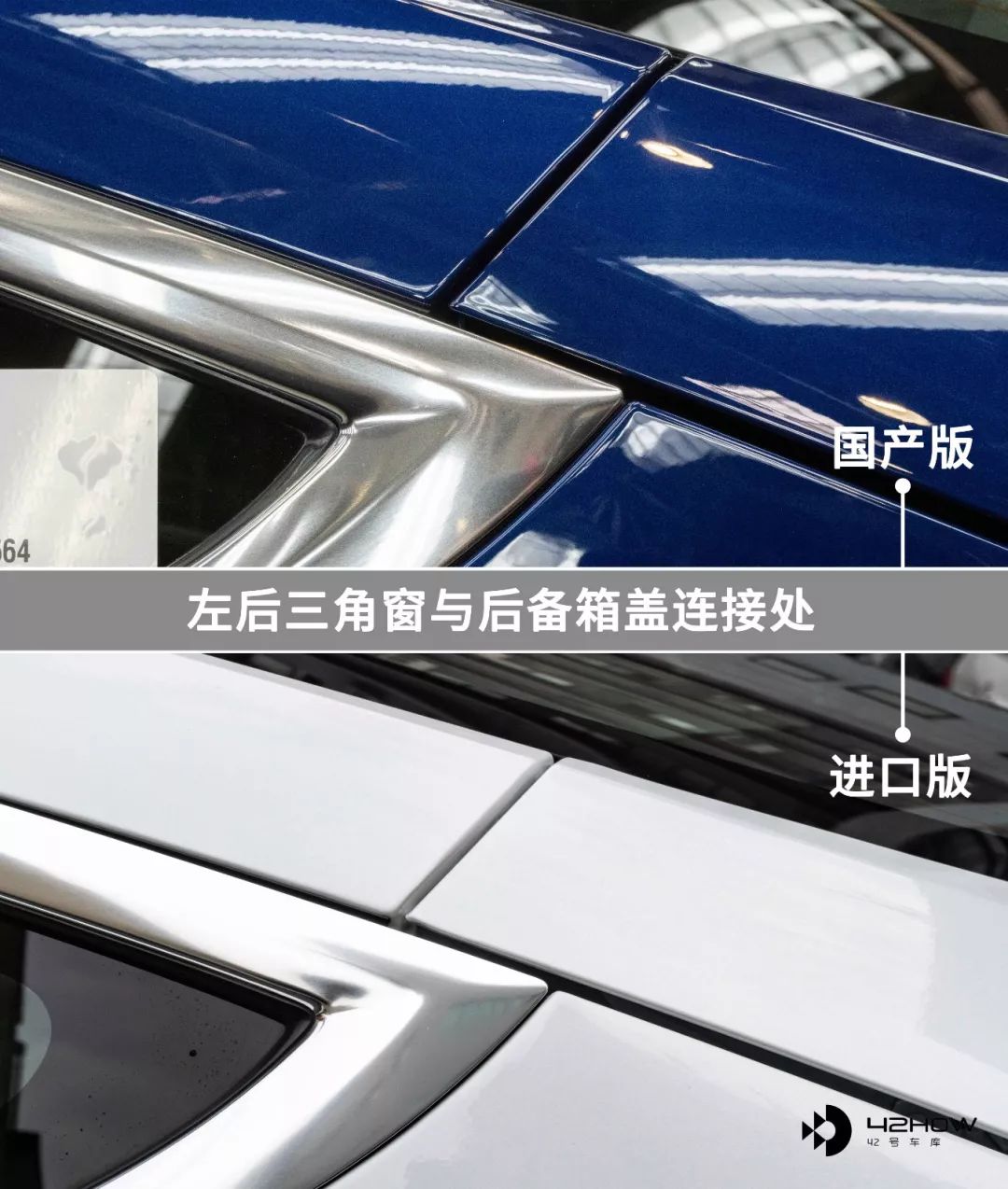

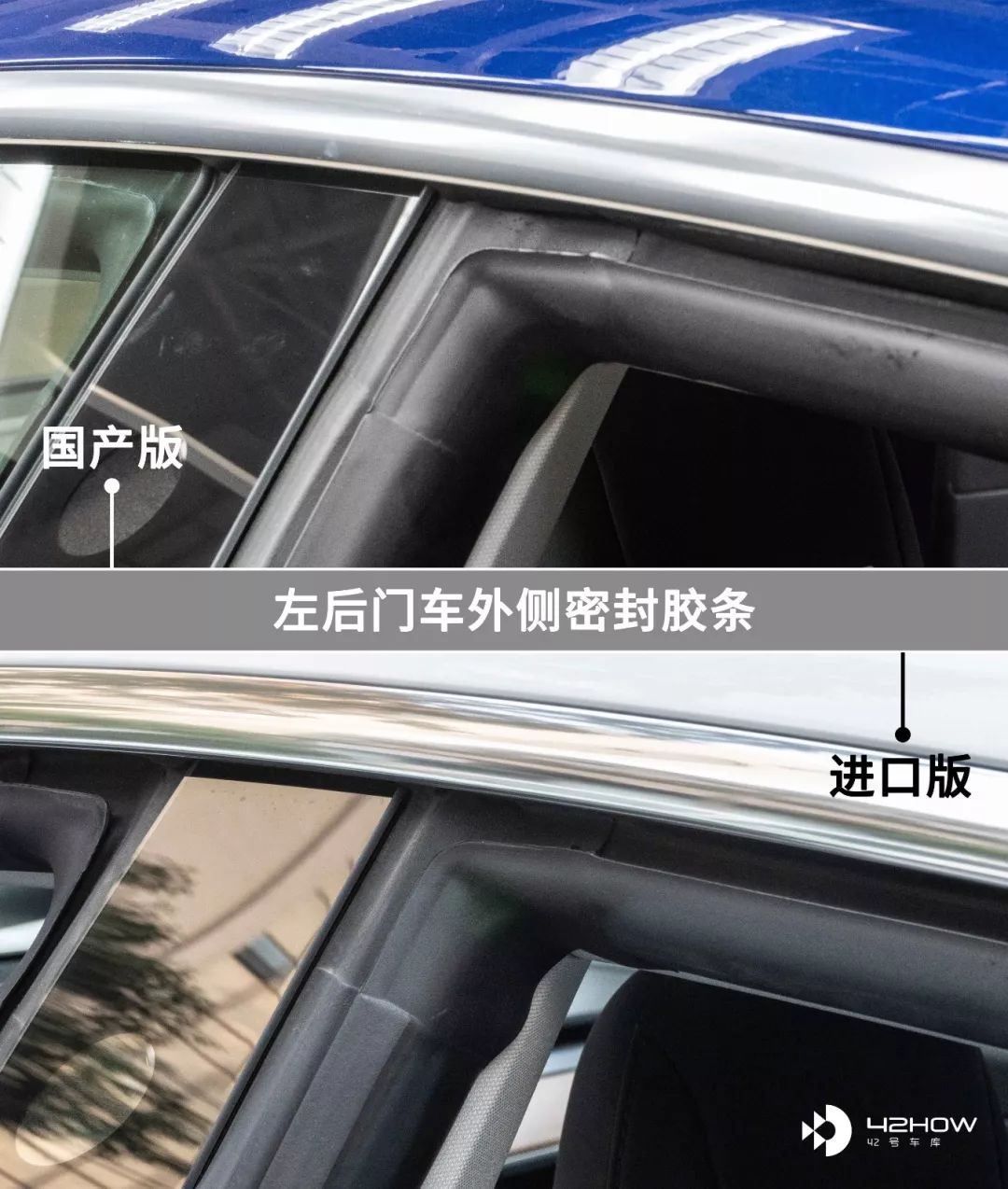

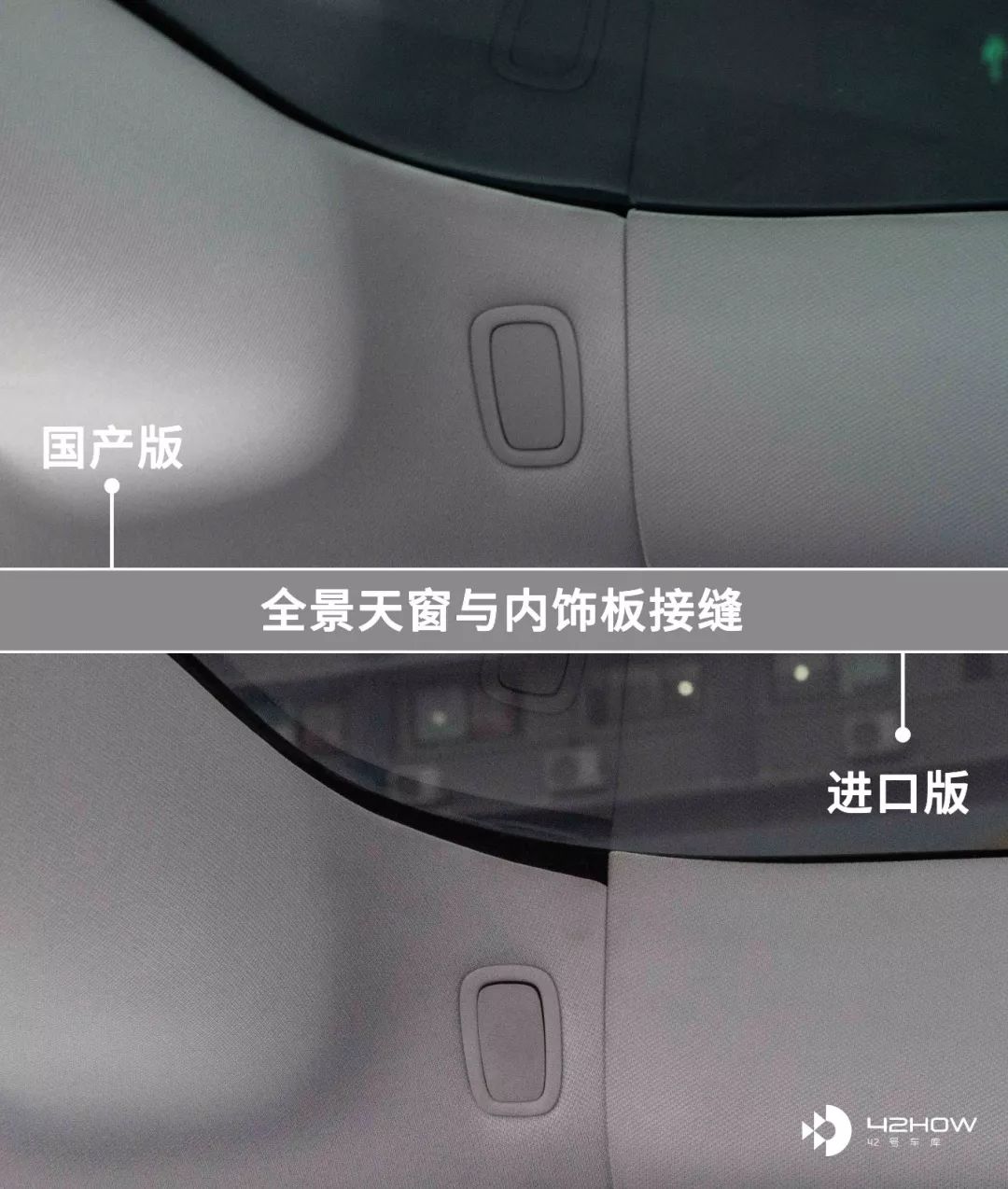

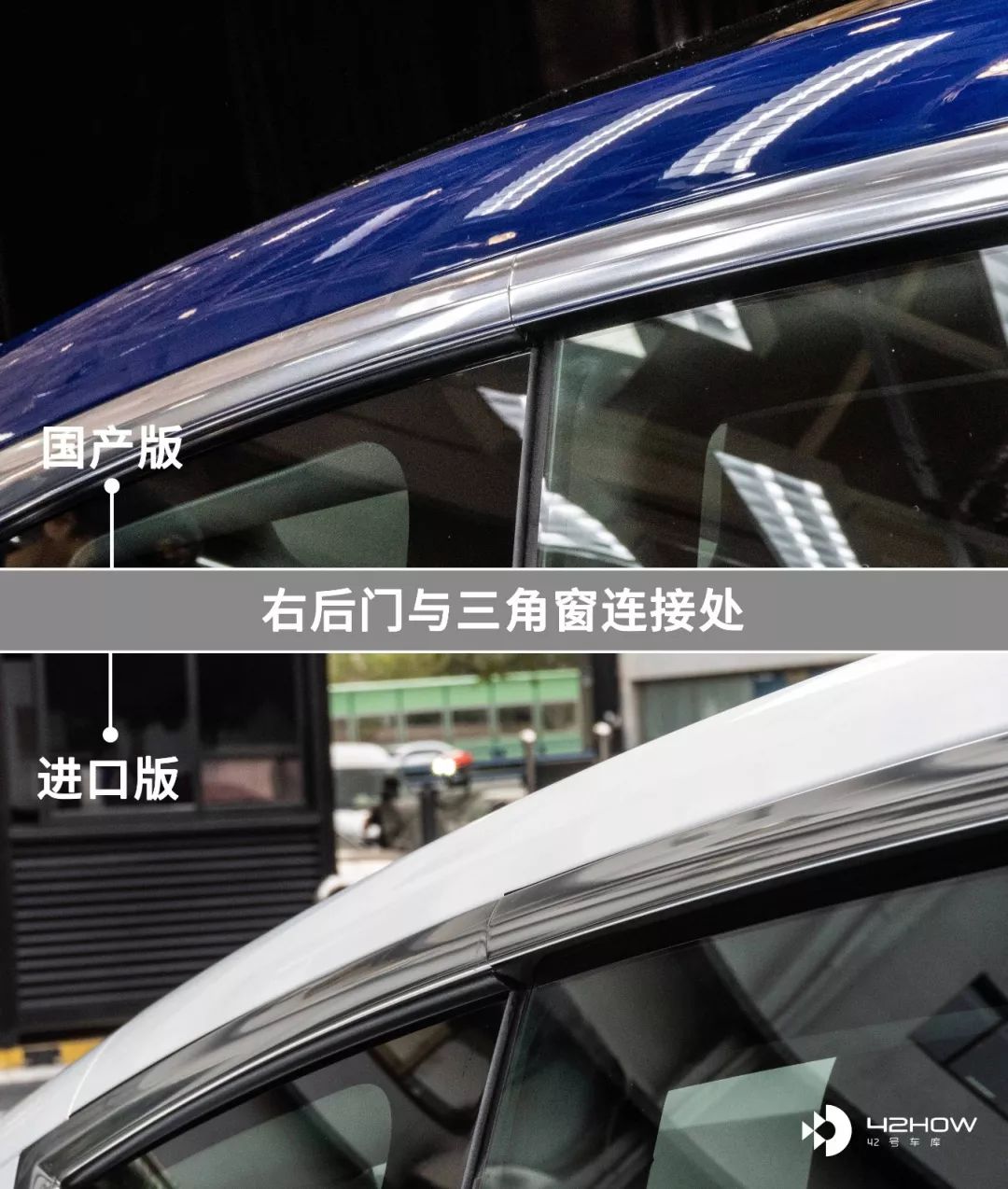

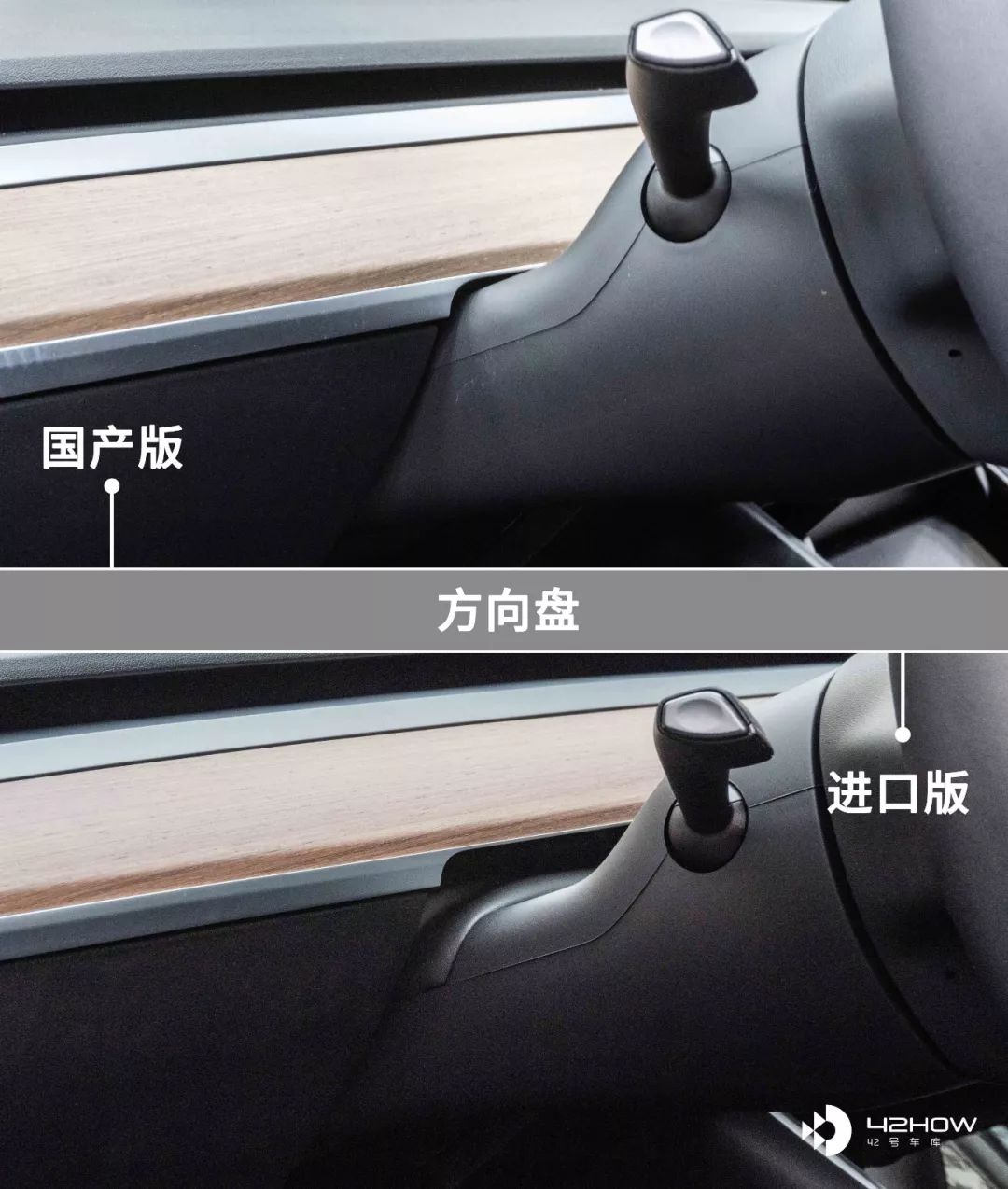

First look at a set of detail comparisons.

swipe the picture to the right

Blue is the domestically produced Model 3 in the factory, and the white is the imported model 3 purchased in the garage of the 42nd in March this year. From the comparison of the details, the domestic version of the Model 3 body The seams of the cover will be smaller, but the overall difference is not big. After we published this set of pictures on Weibo, many people think that there is no difference at all.

I want to say more as a handful of people who have touched the hand. The difference in the size of the gap is not big, but the flatness of the two pieces is better than the imported version. Quite a few, the imported version of the model can clearly feel the gap between the trunk lid and the C-pillar, and the domestic version is basically on a flat surface.

The improvement in the workmanship of the interior is much more obvious than the appearance. The seams of the interior trim panels are smaller and the strips on the doors are more uniform.

Shanghai factory first off the assembly line It is beyond our expectation that the vehicle can reach the current work, in