Computer vision is a discipline that studies “teaching” machines “seeing”

Editor’s note: This article comes from WeChat public account “ Huaxing investment “(ID: iChinaRenaissance ), author: Huaxing new economics Foundation < / span>

This is the third bank research report launched by Huaxing New Economic Fund. As always, we want to share the latest industry insights with you.

This time, we selected the AI field that the fund has long established. As investors in Shangtang and Mingluo, we believe that computer vision is the four major applications of AI (computer vision, speech recognition, natural language understanding, data Mining) is the most technologically mature subdivision track, and competition in the fields of security, finance and medical treatment is particularly fierce.

But the opportunity still exists.

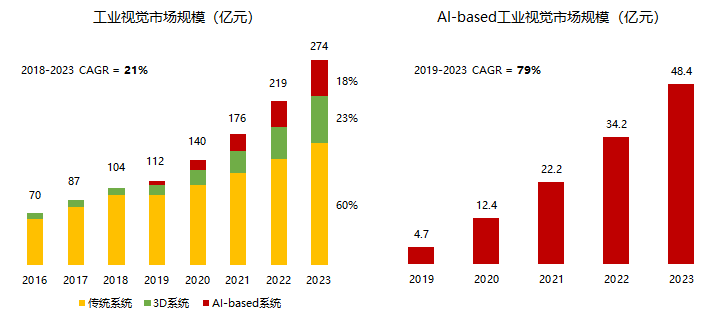

Thanks to AI and 3D technology, industrial vision already has the elements of rapid growth. With a scale of 10 billion + in 2018, we expect that more industrial scenarios will be explored.

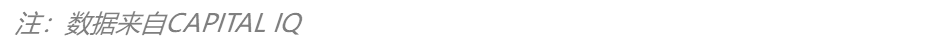

Writing in front: Computer vision is a discipline that studies “teaching” machines to “see”, and allows machines to replace human eyes for various measurements and judgments, including positioning, identification, measurement, and inspection. In addition, computer vision can also be used for graphics processing to produce images that are more suitable for observation by the human eye or transmitted to the instrument for inspection.

p>

Full report:

What is industrial vision?

In simple terms, industrial vision (machine vision) is the use of machines instead of human eyes for various measurements and judgments, such as positioning, identification, measurement, and inspection.

The high speed and stability of industrial vision systems are beyond expectations. For example, scanning packages in high-volume logistics distribution centers, the efficiency of machine system processing is far more manual.

The industrial vision system can easily solve the difficult tasks that people cannot complete such as “accurate measurement without touching the object”.

p>

Why Industrial Vision?

1. Industry trends: China has great potential for automation

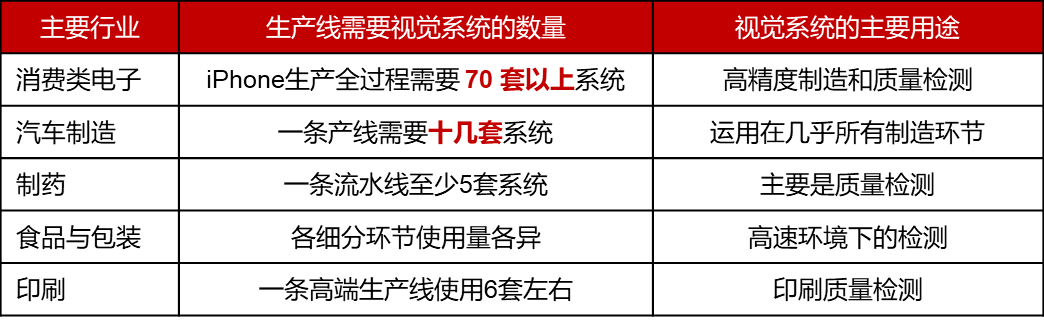

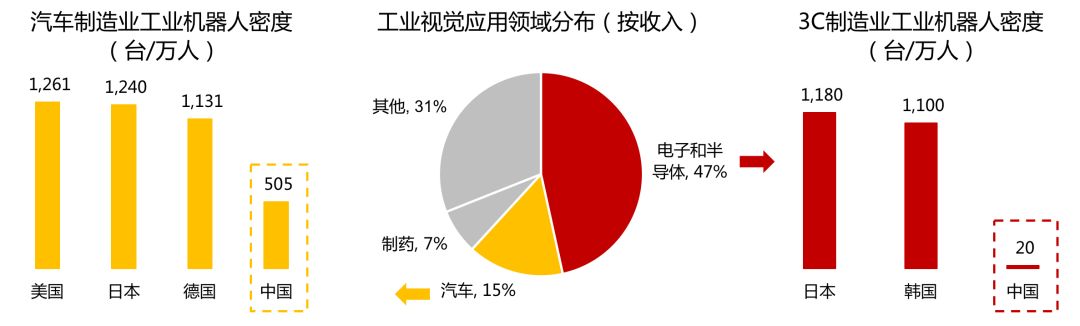

In consumer electronics and automotive manufacturing, the largest application industry of industrial vision, the number of vision systems required for a production line may be as high as a dozen. In these two key industries, China’s industrial robot density is compared with developed countries such as the United States, Japan, South Korea, and Germany.There is still a big gap.

Note: The data comes from the Guangshen Hang Seng Research Report

2. Economic benefits: rising labor costs, prominent industrial visual benefits

In general, if the payback period of the equipment is within 12 months, it will be more attractive to the factory. Taking food packaging inspection as an example, the payback period for factory-installed industrial vision systems is generally 2-8 months, which has obvious economic benefits. In the future, as the cost of labor continues to increase, and the localization of industrial vision components will continue to reduce the price of equipment, the economics of industrial vision systems will become more significant.

Note: The data comes from Pacific Securities Research Report, Huaxing Capital

3. Labor demand: The attractiveness of service industry is increasing, and industrial labor is in short supply

In 2015, the number of Meituan takeaway riders was only 15,000, but by the fourth quarter of 2018, the average daily number of active riders was close to 600,000, and the number of registered hummingbird riders has already exceeded 3 million. people.

Post-80s and 90s are the backbone of the Meituan rider group, accounting for 82%. worth itNote that 31% of riders had previous jobs as industrial workers. The reasons for leaving are generally inflexible working hours and low income. The biggest attraction of this position for takeaway riders is that they work harder (usually 6-8 thousand), followed by free working hours.

4. Underlying technology promotion: artificial intelligence sets off a whirlwind of industry change

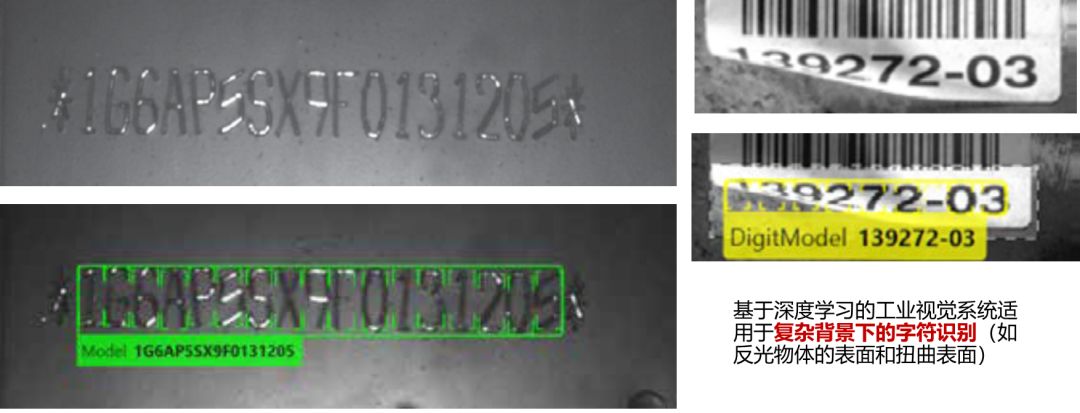

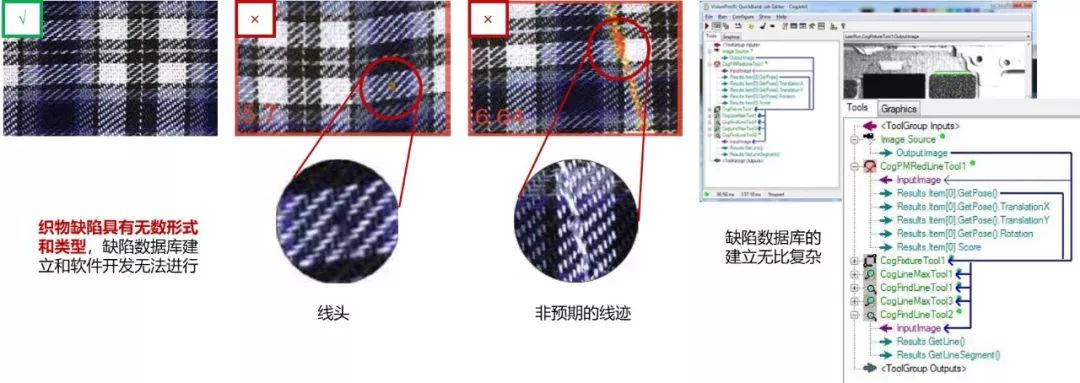

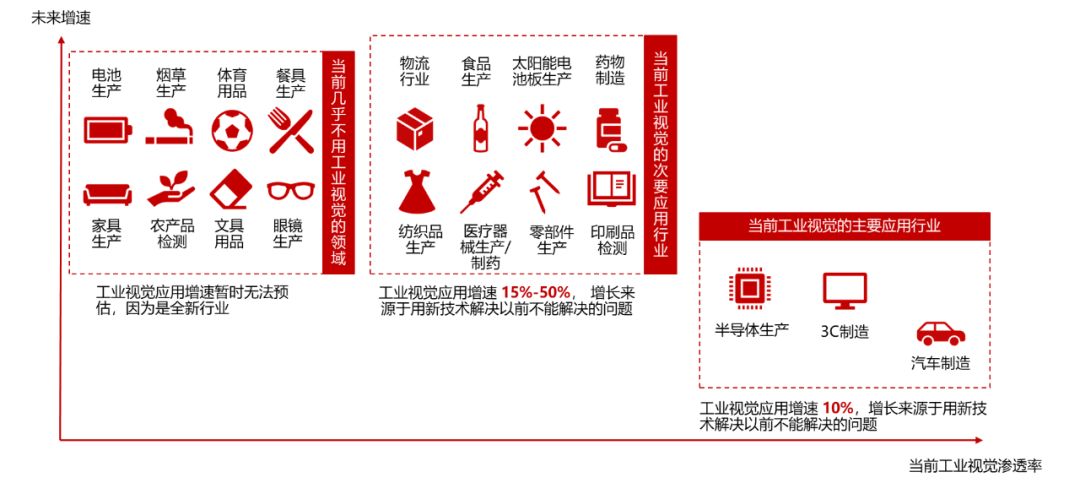

First, traditional industrial vision is powerless in many complex environments. The emergence of artificial intelligence, especially deep learning, has greatly improved industrial vision systems in many aspects (such as character recognition capabilities).

Second, the deep learning vision system has greatly liberated programmer productivity.

The programming difficulty of some traditional industrial vision inspection systems is beyond imagination. Traditional industrial vision systems rely on rule-based algorithms, where defects are manually written by programmers. As the defect database grows larger, the algorithms become more complex.

But in the case of “known qualified components” image set, the deep learning vision system only needs 10-30 minutes of learning time to start inspection without any needSpecific software development and defect database establishment.

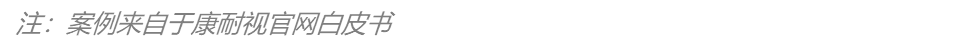

In addition, it is encouraging that the new technology led by artificial intelligence can not only solve the unsolved problems of the existing application industry of industrial vision, but also open up new application fields for us.

In the future, traditional algorithms and AI will cooperate with each other to make industrial vision systems achieve better results.

5. 3D industrial vision technology advancement: potential applications increase

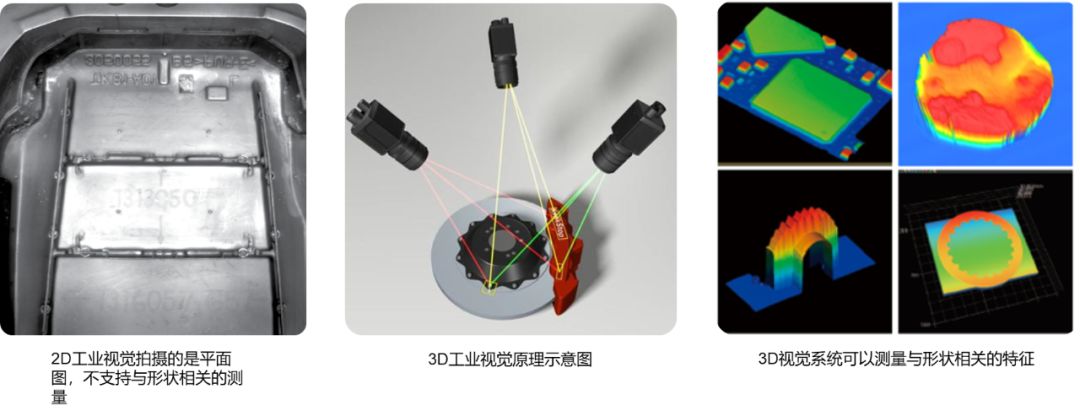

In the 2D vision system, the camera first takes a photo of a plane, and then uses image analysis to identify features on the plane of the object. 2D vision does not support shape-related measurements, such as object flatness, surface angle, volume, etc., and is very sensitive to the movement of the measured object. Measurement accuracy is also easily affected by variable lighting conditions.

3D vision systems usually consist of multiple cameras at different positions, which can measure shape-related features and have a wider range of applications (such as industrial robots).

What are you looking at?

At present, the industrial vision industry is in the tens of billions of scale, but the future growth potential is huge-currently there are 100 million employees in China’s manufacturing industry, according to the proportion of quality inspection staff 10% -20%, each quality inspection staff annual salary 4 10,000 yuan, industrial vision can replace 10% -20% of the quality inspection staff in the long run, the potential market size may be 100 billion.

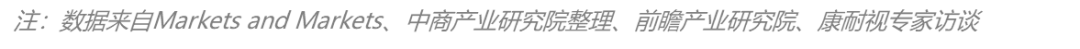

The industrial vision industry chain includes light sources, lenses, industrial cameras, frame grabbers, software, equipment manufacturers / agents / system integrators, etc. We believe that software algorithms and equipment integration have the greatest opportunity for change and are worthy of attention.

However, it should be noted that the simple provision of AI algorithm software cannot meet customer needs. Therefore, industrial vision companies that have AI technology and can provide complete solutions will be sought after. The key capabilities include AI technology level, industry understanding, customer resources, and the ability to provide overall solutions.

Software algorithm

(1) determines the final value of the system and is the most important link in the entire system

The software algorithm is the “brain” of the industrial vision system, which determines the accuracy and value of industrial vision. It is the most important link in the entire system and has a large profit margin. In the past, due to the existence of piracy, domestic manufacturers developed less by themselves (copyright protection has improved for the time being). The Vision Pro developed by Halcon and Cognex developed by foreign MVTech is the most commonly used vision development kit today. Domestic CK Vision’s CK Vision has obvious price advantages compared to the previous toolkits, and it is used in a large amount in China.

(2) The advent of deep learning has given AI startups opportunities to enter the industry.

Industrial vision needs to overcome two “gates” when it expands from the current application scene to new scenes: technology and economics. The advent of deep learning has made it easier to pass the technology. On the one hand, deep learning can help vision systems complete more complex tasks. On the other hand, with the use of deep learning models, workers do not need to build complex databases and software development.

The rules-based software that Cognex and MVTec have polished for decades cannot achieve the functions that AI-based industrial vision systems can achieve. Some AI start-ups, such as Innovation Qizhi, Aqiu Technology, and Elite Vision, have pinpointed the market and used their technical expertise to obtain rapid growth opportunities.

(3) The head company is not big enough, it is an opportunity for AI startups

The provision of AI algorithms in the industrial field alone cannot meet customer needs. OCR applications such asWithout customized development for users, the accuracy of deep learning algorithms is only 80% -90%. On top of this, coupled with standardized software development, the recognition rate can approach 100%. Although Cognex has an AI software platform, it does not provide customized development for mainland customers, leaving sufficient opportunities for AI startups.

The whole machine / agent / system integrator

General integrators will choose the most suitable models and components according to the specific requirements of customers, conduct secondary software development according to the actual needs of the problem, and finally provide customers with a complete set of solutions. There are currently more than 100 companies with integrated businesses in China, of which there are not many large-scale companies.

But for customers, a complete solution is not the same as a pure software platform. They need to solve the practical problems of how to light, how to improve the quality of imaging, and how to design the automation structure. Software vendors also need to have integration capabilities in order to gain customer recognition and put their products on the ground. Similarly, equipment suppliers also need to have software development capabilities (for example, integrator Tianzhun Technology is currently developing software).

Anatomy of cutting-edge companies

1. Case study: COGNEX

Cognex, founded in 1981, is a global leader in providing vision systems, vision software, vision sensors and industrial code readers for manufacturing automation. Cognex independently controls the core image processing software and sensors. Its main product lines include barcode readers, 2D industrial vision systems, 3D industrial vision systems, and image processing software.

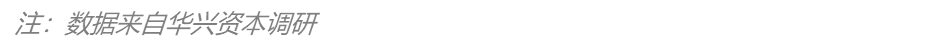

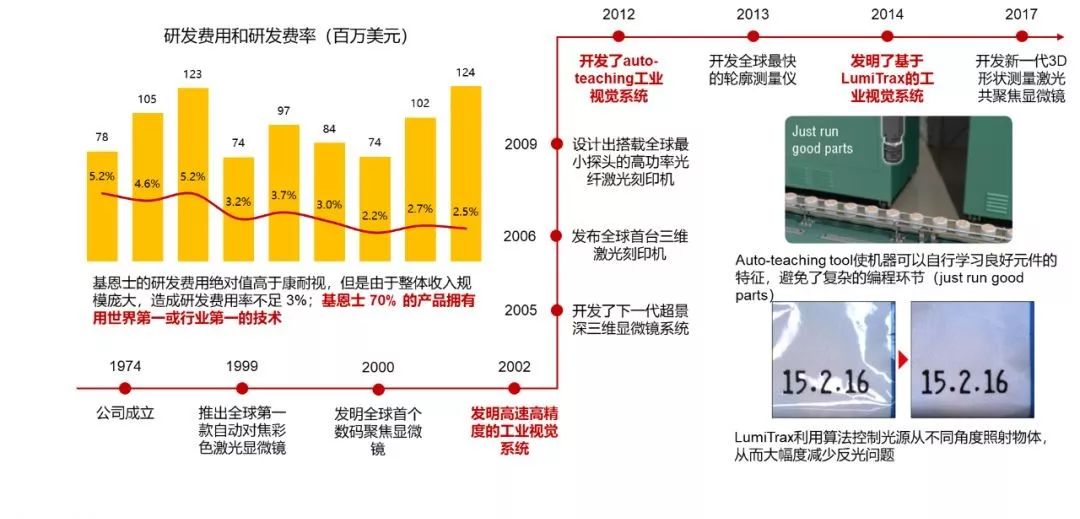

In 2018, Cognex achieved revenue of US $ 806 million and net profit of US $ 219 million. During the five-year period from 2013 to 2018, the company’s annualized revenue was in line with a growth rate of 21% and its net profit compound growth rate was 24%.

In the production process, the company mainly adopts the asset-light model. Although it provides customers with turn-key projects, most parts of the company’s products are purchased, assembled and initially tested by third-party foundries (mostly located in Indonesia). Completed, the company is only responsible for managing the entire supply chain system (such as providing a list of optional component manufacturers). After the initial testing of the product is completed, it will be pulled back to the company’s factory in Massachusetts (for the US) or in Ireland (for overseas) to install software and perform quality inspection, and finally ship it.

In terms of sales, the company mainly focuses on high-volume (focusing on large customers) and high-standard (such as automotive) industries, and try to avoid some small non-standard integration or applications.

The company has formed several deep moats: (1) powerful software algorithm strength (the company’s Vision Pro software is one of the most commonly used platforms in the industry), which can support the company’s continuous introduction of advanced products and support for the market The company continues to enter new downstream fields (such as the logistics industry mentioned earlier); (2) a complete product line; (3) leading the industry technology (such as the company’s continuous research and development and mergers and acquisitions in the field of deep learning and 3D in recent years).

M & A is an important means for Cognex to continue to grow and become a global company. M & A is mainly in four directions: (1) expanding product lines; (2) acquiring the most advanced technology; (3) expanding customer base or Enter new fields; (4) Expand dealer network. From 2015 to 2017, the company completed a total of 7 small mergers and acquisitions, including the $ 23 million acquisition of deep learning company VidiSystems and the launch of related products. The company is still in a state of zero debt operation.

2. Case study: KEYENCE

Keyence is an IKEA industrial vision manufacturer founded in Osaka, Japan. It is a major supplier of sensors and measuring instruments. Keyence’s products include sensors, gauges / measuring sensors, measurement systems, safety protectors, flow / level sensors / pressure sensors / recorders, static eliminators, vision systems / image sensors / bar code readers, control systems (PLC, HMI, motor, etc.), laser marking machine / laser engraving machine / printer / inkjet marking machine, microscope / 3D microscope system, handheld terminal.

In 2018, Cognex achieved revenues of US $ 4.95 billion and a net profit of US $ 1.98 billion. During the five years from 2013 to 2018, the company’s annualized revenue has grown in line with a growth rate of 17%, and its net profit compound growth rate has been 23%.

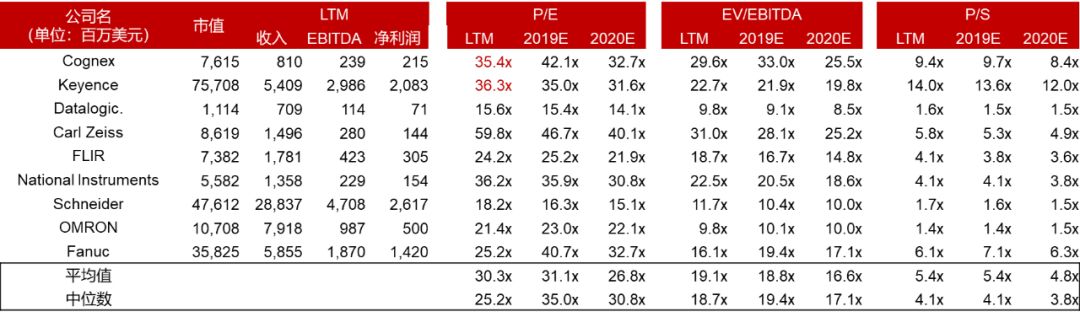

3. Valuation level of relevant representative companies: 35 times P / E, 23-30 times EV / EBITDA