The film “Terminator: Dark Destiny” has an inconspicuous beginning:

When the heroine’s younger brother came to work, he found that his job had been replaced by a robot. His sister rushed to find a supervisor theory, and got a “This is the future” response.

Similarly, human beings are threatened or even backfired by the constantly developing artificial intelligence in literary works. The replacement of repetitive labor positions by robots is also a foreseeable consequence of the highly developed automation.

In the past few years, you may think that this kind of thing is far from yourself. After all, the cost of large-scale use of robots is not cheaper than manual labor, and the completion of some operations is not satisfactory. Until recently, the failure of automation News is still confirming people’s judgments: Japanese robotic hotels “fired” half of their robots due to inefficiency ; Tesla factory is overly automated As a result, the ramp-up of Model 3 production capacity was slow; Adidas’ closing of the robot factory was also presumed to be costly and unable to mass produce.

▲ Adidas’ Robot Factory Plan Announces Failure

It seems that automation just looks beautiful. It’s too early for robots to kill away manual labor, but is this really the case?

Reduced labor cost of robots

In a kitchen in a corner building in downtown Pasadena, the robot Flippy grabbed a basket full of chicken sticks and immersed it in hot oil. After the temperature was confirmed by the sensor, the basket was lifted and drained. Dry and pour chicken strips into a colander.

Not far away, another Flippy watched the beef sizzling in a frying pan. It transmitted the image to the brain’s machine vision system through the camera on the eye. After the beef had the correct brown shadow, use A shovel-like robot scoops out the beef and places it on a burger, and then places the burger on a tray.

Flippy is a robot created by Miso Robotics for corporate kitchens, which deals with dangerous, cumbersome and time-oriented cooking, such as flipping burgers, fried chicken, chopping vegetables, etc. In other words, the lowest paid jobs in restaurants.

Note that the above scenario took place in 2016. The purpose of Miso Robotics is clear: to make robots work like humans on the fast food production line, and the cost is lower than the minimum wage.

Flippy was not cheap at first, and it cost $ 100,000, but due to the rapid decrease in hardware costs, its price has dropped to less than $ 10,000 in 2020, and it will soon be cheaper and more space-efficient. Debut model.

▲ Miso Robotics claims that Flippy can increase the restaurant’s profit margin from 5% to 14%. Picture from: Miso Robotics

This is not over yet. To further impress restaurant owners, Miso Robotics has also launched a subscription system that can hire a robot to help the back kitchen for $ 2,000 a month, which is equivalent to about $ 3 per hour in labor costs. For the same job, if you hire a real employee, depending on the restaurant’s operating hours and the minimum wage in different regions, it will cost 4,000 to 10,000 dollars per month. Besides, the robot never needs to take sick leave. It can run 24 × 7 hours if you like.

Flippy is currently in use at the Dodge Stadium and the fast food chain CaliBurger. Perhaps Americans will soon be able to eat robotic burgers at various fast food restaurants. Maybe the cost of labor will be lower and the price of food will be even higher. Cheap.

Flippy is expected to address the long-standing shortage of people in the catering industry. Consumer demand for fast food is growing, but lower salaries have led to high turnover rates in the restaurant industry, exceeding 100% annually (United States).

Work eliminated by robots

Just as early computers often occupied the entire room to store data, in most cases, even if the robot can complete the work, its working environment will most likely need to be significantly modified, rather than plug and play, let alone with Humans work together safely, so since the first robot appeared, many times the robot cannot be used on a large scale in industry due to its high cost.

Today, the motor engine and sensor technology have been improved, and the cost has been greatly reduced. Flippy and other robots are not only cheap and reliable, but also work in normal environments.People’s anxiety and even panic.

It’s not just restaurant staff. Automation is invading the workforce in all directions, and it’s coming faster than expected.

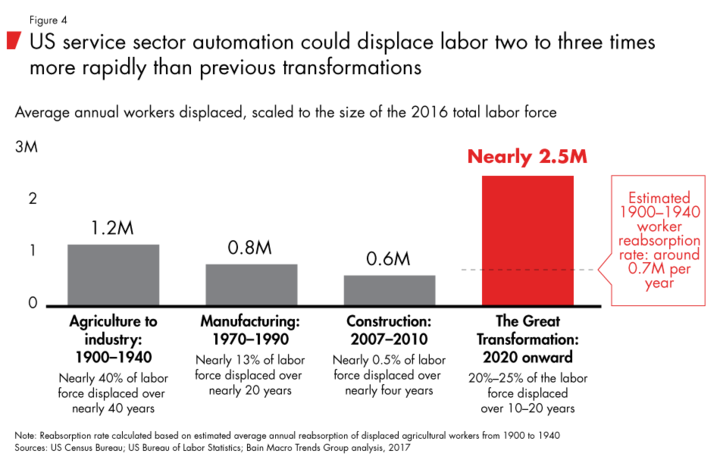

▲ Automation of the US service industry is replacing labor at a rate 2-3 times faster than in the past. Picture from: Bain’s official website

A report issued by Bain & Company in 2018 《 Workforce 2030 “ attracted much attention because it discussed the impact of automation on the social environment. The report predicts that by 2030, the popularity of automation will reduce the current 20% -25% of jobs, which means 40 million people Will be replaced by machines, and this is only in the United States.

To make matters worse, even if employees who keep their jobs, their wage growth will be slower.Many, for example, restaurants use automatic ordering machines and online ordering systems, which may cost less than hiring waiters. Therefore, if the waiter ’s salary stays below this level, there is no need to worry about employment issues, but the wage increase will become extremely extreme. limited. JL Warren Capital’s report also pointed out that Tesla’s Shanghai plant is less automated than its California plant because Shanghai’s labor costs are lower than the costs of the fully automated industry.

Bain’s analysis shows that in the next few decades, approximately 80% of workers will be affected by stagnant wage growth or unemployment, and Flippy’s example has told us that the cost of automation will only get lower and lower.

The outbreak of the new crown pneumonia epidemic has also made many industries that originally depended on manpower see or rethink the need for automation. In addition to reducing labor costs and improving production efficiency, robots can also be fearless in the face of viruses. In the context of promoting “non-contact”, we can also see the application of robots in food delivery, disinfection, body temperature and other scenarios.

Machine substitution is the general trend.

Of course, automation is not all bad news for employment. Robots eliminate old jobs, but new technology also means new job opportunities, just as computers let typists exit the stage of history, they also create Like new careers such as software developers and computer technicians, the popularity of automation will inevitably expand the demand for machine maintenance personnel. Behind the rapid development of the AI industry, the team of “data taggers” is also growing.

Some scholars have taken personal computers as an example, pointing out that automation may not necessarily kill a certain profession. “When spreadsheet software first appeared, everyone was predicting that bookkeeping and accounting would be done,” said Ken Goldberg, an engineering professor at the University of California, Berkeley. “Actually it changed Work, so accountants do n’t have to spend a whole day countingAdd numbers to the calculator, but start data visualization and planning. “

▲ Picture from: Unsplash

However, from an individual perspective, finding a way out in the wave of automation is not easy. Regardless of whether it is a new type of work or optimization efficiency, the technical threshold is obviously higher and higher. Waiters are robbed of work by ordering machines. How many can be transformed into machine maintenance personnel? After the factory is equipped with a fully automatic assembly line, how many workers have the ability to repair the machine?

Moreover, this round of automation not only threatens manual workers, but grassroots white-collar workers with low technical content are also facing the fate of being eliminated. To borrow a phrase that has been widely quoted recently, “A piece of ash of the age falls on a person’s head and is a mountain.”

Fortunately, the high probability of low-tech labor being replaced by machines is a gradual process. There is always a chance to move to other labor-intensive areas. The restaurant job is gone. You can also take out food delivery and express delivery. People lose their jobs overnight.

The invasion of the labor market by automation technology is not a phenomenon since the advent of AI. Agricultural automation in the United States from 1900 to 1940 caused millions of farmers to become unemployed. It was considered one of the causes of the Great Depression. The dishwasher is even more threatening to wipe out the entire kitchen work.

▲ Picture from: “Terminator: Dark Destiny” screenshot

Under the dual impact of the epidemic and the plunge in oil prices, U.S. stocks have recorded their highest single-day declines after 1987 and 1929. European multi-national stock markets have fallen into a technical bear market. The shadow of the economic recession has enveloped the world, represented by the Internet and artificial intelligence. At the same time as the expansion of high-tech productivity, it is also considered to have widened the gap between the rich and the poor.

History seems to have entered a new cycle, but compared to the last century, the pace of technological change is obviously faster and faster, and less time is left for people to adapt.

Title picture from: Unsplash