Major suppliers such as Samsung may see double-digit gains in the next quarter.

Editor’s note: This article comes from the WeChat public account “Machine Power” (ID: almosthuman2017) , author: Van snow, editor: April; published with permission.

However, the market still shows concern about the capacity of NAND. Under the influence of the epidemic, the demand for cloud services has accelerated and the demand for NAND storage has also increased. In addition, as countries and regions began to implement remote office and remote education for the control of the epidemic, the demand for laptop computers has risen rapidly, and they are now out of stock, thereby increasing the demand for NAND storage.

As of 16:00 on April 17th, the cumulative number of diagnoses in Japan has reached more than 9000 cases, and the recent epidemic situation in Japan has been growing faster. The total number of diagnoses in the world has jumped from 30 to 24 after 30 weeks ago .

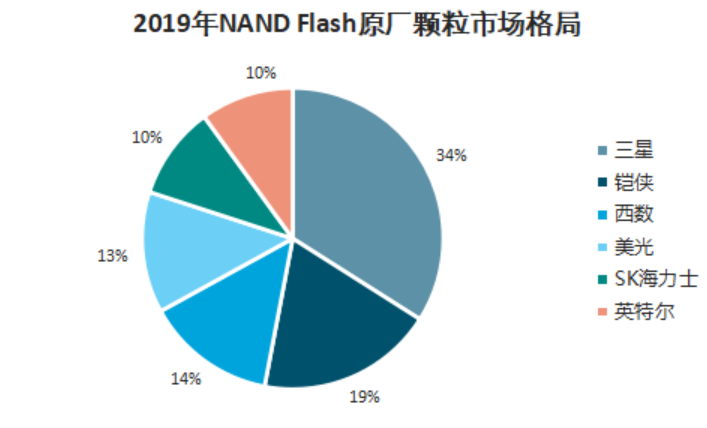

At present, it can only be said that “not yet” is affected, but if the epidemic cannot be controlled in time, the production of the armor will be affected. Toshiba currently occupies more than one-fifth of the global NAND market. Once the production capacity is affected, the entire market structure and product prices will inevitably have feedback.

Inside the Toshiba factory

One of the reasons for the large-scale shutdown was an employee infection within Toshiba. According to Toshiba ’s official website, 5 people have been diagnosed in a factory located in the suburbs of Tokyo. In addition, the shutdown is also a call to the Japanese government to reduce staff 8 Response to contact.

According to the Japanese epidemic map, Tokyo is the hardest hit by Japan ’s new crown epidemic. As of April 15, the cumulative number of confirmed cases has reached 2,446, and the number of new cases reached 127 on that day.

At present, major manufacturers are intensively negotiating with the module manufacturers for the second quarter contract price.

Previously, according to unnamed channel providers, major suppliers including Samsung and others have notified to increase DRAM and NAND Flas next seasonh The contract price has increased by double digits! Will Toshiba, Japan’s largest semiconductor company, also make defensive adjustments?

After Toshiba ’s work stoppage , Can the armored man be protected from “the disaster of pond fish”?

Toshiba is currently Japan’s largest semiconductor manufacturer. In 1984, Toshiba developed a new type of semiconductor memory and named it flash memory (NOR). In 1987, Toshiba developed NAND flash memory (NAND).

Toshiba flash memory chip

Since then, NAND has been used in various memory cards and electronic products. The NAND market is developing rapidly, and NAND flash memory has also become an international standard storage device.

Since then, Toshiba first proposed the architecture, and successfully developed a 16-layer 3D NAND experiment in 2012. 3D NAND has been regarded as the latest technological process direction by the industry.

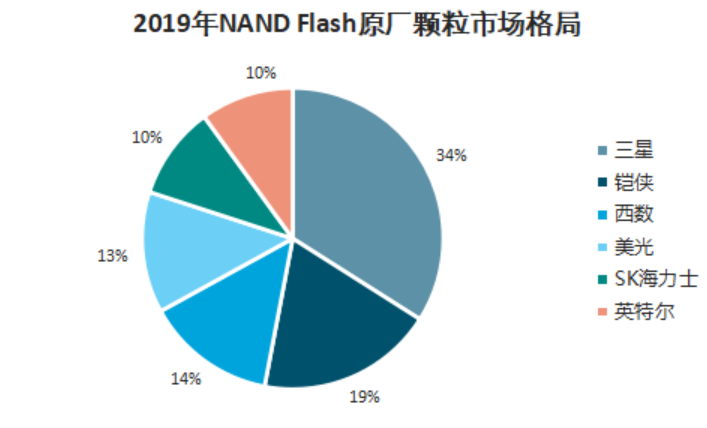

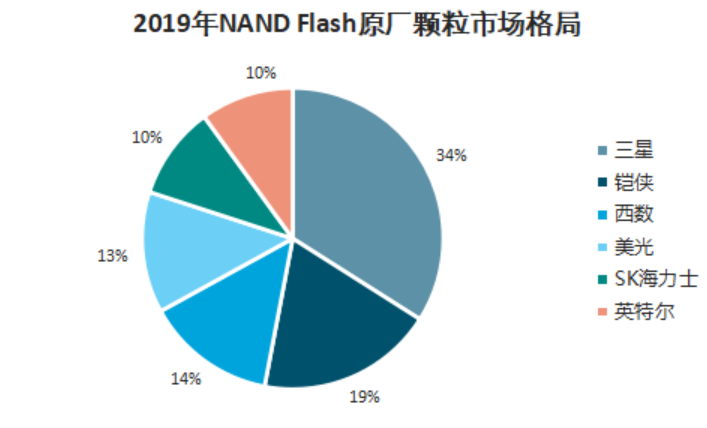

According to the Strategy Analytics report, the total revenue of smartphone NAND flash memory declined by 29% in 2019. % Revenue share continues to dominate the NAND flash memory market,Kioxia) and SK Hynix account for 22% and 16% of the revenue respectively.

Caixia was renamed from Toshiba Memory. As early as 2017, Toshiba changed its storage business to 20,000 due to financial problems. 100 million yen (approximately RMB 115 billion) was sold to the “Japan-U.S.-South Korea Consortium” dominated by US fund Bain Capital. Although Toshiba still holds more than 40% of its equity, it is its largest shareholder, but its The storage business has been completely independent, and officially changed its name to Kaixia on October 1, 2019.

This also means that Toshiba’s NAND business is currently not affected by the shutdown, and NAND control chip manufacturers On the evening of the 15th, Lianlian also stated that although Toshiba was completely shut down, the armor still operates normally, and the armor’s NAND chips will be normally supplied to Qunlian.

It is understood that Toshiba is the major shareholder of Qunlian, and Qunlian mainly purchases NAND Flash from Toshiba, and the two parties have a cooperative relationship.

However, due to the large scale of the shutdown, external concerns about the industry chain are still fermenting, Communications expert Xiang Ligang said that if a large-scale enterprise shuts down, it will definitely cause a certain degree of negative impact on the industry, especially those with a relatively concentrated industrial chain If the goods cannot be supplied, the downstream will be affected.

In addition, the follow-up impact of the epidemic is still difficult to assess. According to Cailian News Agency, a senior practitioner from Shenzhen said that at present , Can only say that “not yet” is affected, but if the epidemic can not be controlled in time, the production of the armor may be affectedSex also exists.

Given that Armor has a large market share in the entire NAND market, once the capacity is affected, the overall market pattern , The product price is bound to have feedback.

On April 16, the NAND spot spot price did not fluctuate in early trading, and it is still in a trend of continuous slight decline.

The epidemic increases storage demand , Shutdown to accelerate price increases?

For the company of Toshiba, it was not the first time that external factors caused the shutdown, which in turn caused turbulence in the memory. Toshiba has experienced many factory shutdowns due to fires, earthquakes, floods, etc. Brings a big impact on the entire memory market.

On June 15th, 2019, there was a power jump accident at the Armored Mansion. All the factories including Fab2, Fab3, Fab4, Fab5, and Fab6 were impacted, which affected the supply of the entire NAND Flash supply chain. For a whole season.

It is reported that Fab2, Fab3, Fab4, Fab5, Fab6 are all the factories that Kaixia has put into NAND Flash production.

On January 7, 2020, a fire broke out at Fab 6 factory in Yokkaichi, Mie Prefecture, Japan, although the fire was quickly extinguished. However, because the fire occurred in the clean room of the factory, it may cause the factory to fail to operate normally in the short term. The impact on the market is likely to be greater than the previous Samsung power jump event, exacerbating the upward trend of contract prices in the first quarter.

Caixia declared at the time

In addition to the “human disaster”, the biggest unevenness factor this year is the “natural disaster” epidemic. Since the fourth quarter of 2019, the total amount of NAND Flash sales has shown an upward trend. According to the survey of Jibang Consulting Semiconductor Research Center, 2019 In the fourth quarter of 2015, the total sales volume of NAND Flash increased by nearly 10% quarter-on-quarter, and the market gradually exceeded supply.

Under the impact of the epidemic, the demand for cloud services has accelerated and the demand for NAND storage has increased. In addition, as countries and regions began to implement remote office and remote education for the control of the epidemic, the demand for laptop computers has risen rapidly, and they are now out of stock, thereby increasing the demand for NAND storage.

According to Gartner research data, in the case of continuous fermentation of the epidemic, the storage market revenue in 2020 will account for the global 30% of the total semiconductor market, the scale will reach 124.7 billion US dollars, an increase of 13.9%.

In addition to the data center customers actively preparing for the demand driven by the epidemic, the mobile device end is also preparing for the launch of Apple’s new machine in the first half of 2020. Demand for stocks has emerged since the fourth quarter.

Therefore, Jibang Consulting Semiconductor Research Center predicts that, generally speaking, the first quarter of 2020 NAND Flash will show off-season, prices will continue to rise.

Because semiconductor memory is a highly monopolized market, its three mainstream products DRAM, NAND Flash, NOR Flash Even more so, once the armor was affected by the shutdown, the upstream supply was in short supply, under the monopoly market, there was no other way but to increase the price of the product, and the oligopolistic pattern made downstream customers facing the price increase of memory chips without bargaining power.

Potential turbulence behind the shutdown , It is subject to the current situation

Except for Toshiba, affected by the epidemic, many Japanese semiconductor companies such as Nichicon, TDK, Panasonic and other factories are currently closed.

Xie Yaxuan, an analyst at China Merchants Securities, said that once Japan ’s epidemic is severe, Japan will inevitably take severe measures to combat the epidemic. The characteristics of “processing trade” will make China suffer from insufficient supply from upstream countries. , Electronics and optical manufacturing, Electrical manufacturing and other fields have a greater potential impact on China.

In contrast, at present, there are no manufacturers in the NAND field that can compete with overseas manufacturers, even Toshiba executives in September 2019 It has been said that it is not easy for Chinese memory manufacturers to catch up in two or three years, and the situation of oversupply in the market has ended.

However, the breakthrough of Changjiang Storage in the field of 3D NAND may find some opportunities for local memory manufacturers.

On April 13, Changjiang Storage officially released two 128-layer 3D NAND flash memories. Among them, the model X2-6070 product is the industry’s first 128-layer QLC (each storage unit can store 4bit data), which can provide a single storage capacity of 1.33Tb, with the current globalThe highest storage density, highest I / O transfer speed and highest single NAND flash memory chip capacity among the products of known models;

Yangtze River Storage X2-6070

Another model of X2-9060 128-layer TLC (each storage unit can store 3bit data), also has 512Gb storage capacity, the storage array area utilization efficiency exceeds 90% (storage array area / total chip area), I / O transmission speed achieves 1.6Gb / s high performance.

As Gong Yi, Senior Vice President of Changjiang Storage Market and Sales, pointed out in an interview with reporters, this product release shows that Changjiang Storage has basically leveled the international advanced level in the field of 3D NAND flash memory, and even has some Lead.

As a latecomer to the Yangtze River Storage, in fact, as early as 2018, 32-layer 3D NAND flash memory chips have been mass-produced. However, in 2018, each of the 64-layer and 72-layer 3D NAND flash memory was already the main product, and it has already been fully laid out. The gap between the generation behind makes the Yangtze River storage did not attract industry attention at that time.

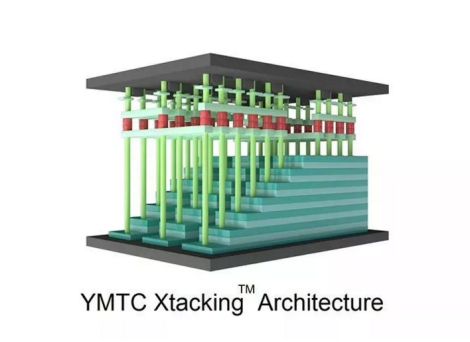

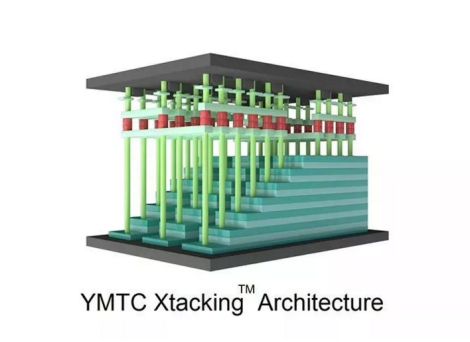

In early September 2019, Changjiang Storage announced the mass production of 64-layer 256GB TLC 3D NAND flash memory based on the Xtacking architecture, and this is also the first time that China has achieved 64-layer 3D Mass production of NADA flash memory chips.

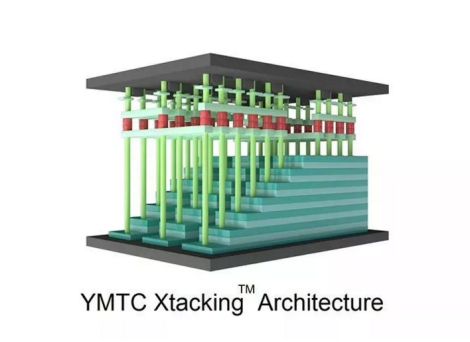

Xtacking architecture

In addition to Yangtze River Storage, domestic companies are currently struggling to catch up. Yangtze River Storage, Hefei Changxin, which focuses on mobile memory, and Fujian Jinhua, which is dedicated to basic memory, form the troika of China’s memory market.

Fujian Jinhua focuses on the development of niche memory (Specialty DRAM), focusing on the consumer electronics market, and is expected to expand its own production capacity with its huge domestic demand market.

Different from Fujian Jinhua, Hefei Changxin directly hits the core mobile memory (Mobile DRAM) of the big international manufacturers, mobile memory It is already the product with the highest proportion in the memory category, and its power-saving technical requirements are extremely high, and the development is very difficult.

Although the three major domestic memory chip manufacturers are catching up with the international advanced level, it is undeniable that the memory chip manufacturers are still in an oligopoly In the competitive landscape, only Zhaoyi Innovation in China’s domestic memory chips has a market share of about 10% in NOR Flash. According to CINNO Research industry research, Zhaoyi Innovation’s NOR Flash global market share achieved a breakthrough in the second quarter of 2019, rising to the fourth in the world. And in the third quarter, it ranked third in the world.

However, the domestic market share of DRAM and NAND in key areas is currently 0.

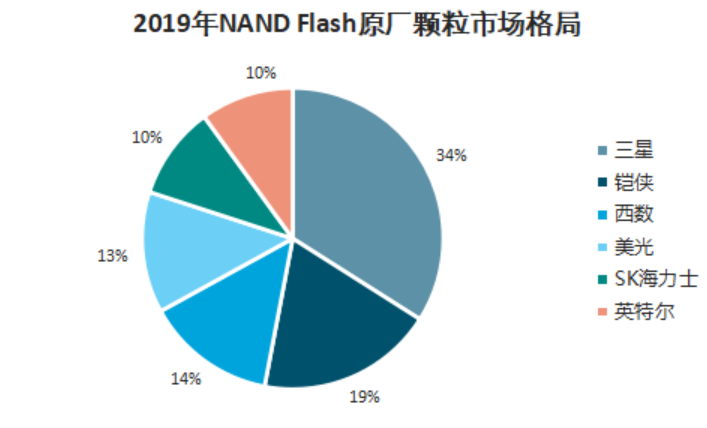

In the NAND Flash market, Samsung, Toshiba, Micron, SK Hynix, Western Digital, Intel These six companies have monopolized more than 99% of the global share for a long time.

If domestic memory chip manufacturers want to catch up, I am afraid that only by working hard on technology can we make up for the historical gap. As semiconductor expert Mo Dakang once said, memory chips have highly standardized characteristics and a single variety, which makes it difficult to achieve product Differentiation requires manufacturers to compete with each other in process technology and production scale.

Toshiba flash memory chip

Since then, NAND has been used in various memory cards and electronic products. The NAND market is developing rapidly, and NAND flash memory has also become an international standard storage device.

Since then, Toshiba first proposed the architecture, and successfully developed a 16-layer 3D NAND experiment in 2012. 3D NAND has been regarded as the latest technological process direction by the industry.

According to the Strategy Analytics report, the total revenue of smartphone NAND flash memory declined by 29% in 2019. % Revenue share continues to dominate the NAND flash memory market,Kioxia) and SK Hynix account for 22% and 16% of the revenue respectively.

Caixia was renamed from Toshiba Memory. As early as 2017, Toshiba changed its storage business to 20,000 due to financial problems. 100 million yen (approximately RMB 115 billion) was sold to the “Japan-U.S.-South Korea Consortium” dominated by US fund Bain Capital. Although Toshiba still holds more than 40% of its equity, it is its largest shareholder, but its The storage business has been completely independent, and officially changed its name to Kaixia on October 1, 2019.

This also means that Toshiba’s NAND business is currently not affected by the shutdown, and NAND control chip manufacturers On the evening of the 15th, Lianlian also stated that although Toshiba was completely shut down, the armor still operates normally, and the armor’s NAND chips will be normally supplied to Qunlian.

It is understood that Toshiba is the major shareholder of Qunlian, and Qunlian mainly purchases NAND Flash from Toshiba, and the two parties have a cooperative relationship.

However, due to the large scale of the shutdown, external concerns about the industry chain are still fermenting, Communications expert Xiang Ligang said that if a large-scale enterprise shuts down, it will definitely cause a certain degree of negative impact on the industry, especially those with a relatively concentrated industrial chain If the goods cannot be supplied, the downstream will be affected.

In addition, the follow-up impact of the epidemic is still difficult to assess. According to Cailian News Agency, a senior practitioner from Shenzhen said that at present , Can only say that “not yet” is affected, but if the epidemic can not be controlled in time, the production of the armor may be affectedSex also exists.

Given that Armor has a large market share in the entire NAND market, once the capacity is affected, the overall market pattern , The product price is bound to have feedback.

On April 16, the NAND spot spot price did not fluctuate in early trading, and it is still in a trend of continuous slight decline.

The epidemic increases storage demand , Shutdown to accelerate price increases?

For the company of Toshiba, it was not the first time that external factors caused the shutdown, which in turn caused turbulence in the memory. Toshiba has experienced many factory shutdowns due to fires, earthquakes, floods, etc. Brings a big impact on the entire memory market.

On June 15th, 2019, there was a power jump accident at the Armored Mansion. All the factories including Fab2, Fab3, Fab4, Fab5, and Fab6 were impacted, which affected the supply of the entire NAND Flash supply chain. For a whole season.

It is reported that Fab2, Fab3, Fab4, Fab5, Fab6 are all the factories that Kaixia has put into NAND Flash production.

On January 7, 2020, a fire broke out at Fab 6 factory in Yokkaichi, Mie Prefecture, Japan, although the fire was quickly extinguished. However, because the fire occurred in the clean room of the factory, it may cause the factory to fail to operate normally in the short term. The impact on the market is likely to be greater than the previous Samsung power jump event, exacerbating the upward trend of contract prices in the first quarter.

Caixia declared at the time

In addition to the “human disaster”, the biggest unevenness factor this year is the “natural disaster” epidemic. Since the fourth quarter of 2019, the total amount of NAND Flash sales has shown an upward trend. According to the survey of Jibang Consulting Semiconductor Research Center, 2019 In the fourth quarter of 2015, the total sales volume of NAND Flash increased by nearly 10% quarter-on-quarter, and the market gradually exceeded supply.

Under the impact of the epidemic, the demand for cloud services has accelerated and the demand for NAND storage has increased. In addition, as countries and regions began to implement remote office and remote education for the control of the epidemic, the demand for laptop computers has risen rapidly, and they are now out of stock, thereby increasing the demand for NAND storage.

According to Gartner research data, in the case of continuous fermentation of the epidemic, the storage market revenue in 2020 will account for the global 30% of the total semiconductor market, the scale will reach 124.7 billion US dollars, an increase of 13.9%.

In addition to the data center customers actively preparing for the demand driven by the epidemic, the mobile device end is also preparing for the launch of Apple’s new machine in the first half of 2020. Demand for stocks has emerged since the fourth quarter.

Therefore, Jibang Consulting Semiconductor Research Center predicts that, generally speaking, the first quarter of 2020 NAND Flash will show off-season, prices will continue to rise.

Because semiconductor memory is a highly monopolized market, its three mainstream products DRAM, NAND Flash, NOR Flash Even more so, once the armor was affected by the shutdown, the upstream supply was in short supply, under the monopoly market, there was no other way but to increase the price of the product, and the oligopolistic pattern made downstream customers facing the price increase of memory chips without bargaining power.

Potential turbulence behind the shutdown , It is subject to the current situation

Except for Toshiba, affected by the epidemic, many Japanese semiconductor companies such as Nichicon, TDK, Panasonic and other factories are currently closed.

Xie Yaxuan, an analyst at China Merchants Securities, said that once Japan ’s epidemic is severe, Japan will inevitably take severe measures to combat the epidemic. The characteristics of “processing trade” will make China suffer from insufficient supply from upstream countries. , Electronics and optical manufacturing, Electrical manufacturing and other fields have a greater potential impact on China.

In contrast, at present, there are no manufacturers in the NAND field that can compete with overseas manufacturers, even Toshiba executives in September 2019 It has been said that it is not easy for Chinese memory manufacturers to catch up in two or three years, and the situation of oversupply in the market has ended.

However, the breakthrough of Changjiang Storage in the field of 3D NAND may find some opportunities for local memory manufacturers.

On April 13, Changjiang Storage officially released two 128-layer 3D NAND flash memories. Among them, the model X2-6070 product is the industry’s first 128-layer QLC (each storage unit can store 4bit data), which can provide a single storage capacity of 1.33Tb, with the current globalThe highest storage density, highest I / O transfer speed and highest single NAND flash memory chip capacity among the products of known models;

Yangtze River Storage X2-6070

Another model of X2-9060 128-layer TLC (each storage unit can store 3bit data), also has 512Gb storage capacity, the storage array area utilization efficiency exceeds 90% (storage array area / total chip area), I / O transmission speed achieves 1.6Gb / s high performance.

As Gong Yi, Senior Vice President of Changjiang Storage Market and Sales, pointed out in an interview with reporters, this product release shows that Changjiang Storage has basically leveled the international advanced level in the field of 3D NAND flash memory, and even has some Lead.

As a latecomer to the Yangtze River Storage, in fact, as early as 2018, 32-layer 3D NAND flash memory chips have been mass-produced. However, in 2018, each of the 64-layer and 72-layer 3D NAND flash memory was already the main product, and it has already been fully laid out. The gap between the generation behind makes the Yangtze River storage did not attract industry attention at that time.

In early September 2019, Changjiang Storage announced the mass production of 64-layer 256GB TLC 3D NAND flash memory based on the Xtacking architecture, and this is also the first time that China has achieved 64-layer 3D Mass production of NADA flash memory chips.

Xtacking architecture

In addition to Yangtze River Storage, domestic companies are currently struggling to catch up. Yangtze River Storage, Hefei Changxin, which focuses on mobile memory, and Fujian Jinhua, which is dedicated to basic memory, form the troika of China’s memory market.

Fujian Jinhua focuses on the development of niche memory (Specialty DRAM), focusing on the consumer electronics market, and is expected to expand its own production capacity with its huge domestic demand market.

Different from Fujian Jinhua, Hefei Changxin directly hits the core mobile memory (Mobile DRAM) of the big international manufacturers, mobile memory It is already the product with the highest proportion in the memory category, and its power-saving technical requirements are extremely high, and the development is very difficult.

Although the three major domestic memory chip manufacturers are catching up with the international advanced level, it is undeniable that the memory chip manufacturers are still in an oligopoly In the competitive landscape, only Zhaoyi Innovation in China’s domestic memory chips has a market share of about 10% in NOR Flash. According to CINNO Research industry research, Zhaoyi Innovation’s NOR Flash global market share achieved a breakthrough in the second quarter of 2019, rising to the fourth in the world. And in the third quarter, it ranked third in the world.

However, the domestic market share of DRAM and NAND in key areas is currently 0.

In the NAND Flash market, Samsung, Toshiba, Micron, SK Hynix, Western Digital, Intel These six companies have monopolized more than 99% of the global share for a long time.

If domestic memory chip manufacturers want to catch up, I am afraid that only by working hard on technology can we make up for the historical gap. As semiconductor expert Mo Dakang once said, memory chips have highly standardized characteristics and a single variety, which makes it difficult to achieve product Differentiation requires manufacturers to compete with each other in process technology and production scale.

Caixia declared at the time

In addition to the “human disaster”, the biggest unevenness factor this year is the “natural disaster” epidemic. Since the fourth quarter of 2019, the total amount of NAND Flash sales has shown an upward trend. According to the survey of Jibang Consulting Semiconductor Research Center, 2019 In the fourth quarter of 2015, the total sales volume of NAND Flash increased by nearly 10% quarter-on-quarter, and the market gradually exceeded supply.

Under the impact of the epidemic, the demand for cloud services has accelerated and the demand for NAND storage has increased. In addition, as countries and regions began to implement remote office and remote education for the control of the epidemic, the demand for laptop computers has risen rapidly, and they are now out of stock, thereby increasing the demand for NAND storage.

According to Gartner research data, in the case of continuous fermentation of the epidemic, the storage market revenue in 2020 will account for the global 30% of the total semiconductor market, the scale will reach 124.7 billion US dollars, an increase of 13.9%.

In addition to the data center customers actively preparing for the demand driven by the epidemic, the mobile device end is also preparing for the launch of Apple’s new machine in the first half of 2020. Demand for stocks has emerged since the fourth quarter.

Therefore, Jibang Consulting Semiconductor Research Center predicts that, generally speaking, the first quarter of 2020 NAND Flash will show off-season, prices will continue to rise.

Because semiconductor memory is a highly monopolized market, its three mainstream products DRAM, NAND Flash, NOR Flash Even more so, once the armor was affected by the shutdown, the upstream supply was in short supply, under the monopoly market, there was no other way but to increase the price of the product, and the oligopolistic pattern made downstream customers facing the price increase of memory chips without bargaining power.

Potential turbulence behind the shutdown , It is subject to the current situation

Except for Toshiba, affected by the epidemic, many Japanese semiconductor companies such as Nichicon, TDK, Panasonic and other factories are currently closed.

Xie Yaxuan, an analyst at China Merchants Securities, said that once Japan ’s epidemic is severe, Japan will inevitably take severe measures to combat the epidemic. The characteristics of “processing trade” will make China suffer from insufficient supply from upstream countries. , Electronics and optical manufacturing, Electrical manufacturing and other fields have a greater potential impact on China.

In contrast, at present, there are no manufacturers in the NAND field that can compete with overseas manufacturers, even Toshiba executives in September 2019 It has been said that it is not easy for Chinese memory manufacturers to catch up in two or three years, and the situation of oversupply in the market has ended.

However, the breakthrough of Changjiang Storage in the field of 3D NAND may find some opportunities for local memory manufacturers.

On April 13, Changjiang Storage officially released two 128-layer 3D NAND flash memories. Among them, the model X2-6070 product is the industry’s first 128-layer QLC (each storage unit can store 4bit data), which can provide a single storage capacity of 1.33Tb, with the current globalThe highest storage density, highest I / O transfer speed and highest single NAND flash memory chip capacity among the products of known models;

Yangtze River Storage X2-6070

Another model of X2-9060 128-layer TLC (each storage unit can store 3bit data), also has 512Gb storage capacity, the storage array area utilization efficiency exceeds 90% (storage array area / total chip area), I / O transmission speed achieves 1.6Gb / s high performance.

As Gong Yi, Senior Vice President of Changjiang Storage Market and Sales, pointed out in an interview with reporters, this product release shows that Changjiang Storage has basically leveled the international advanced level in the field of 3D NAND flash memory, and even has some Lead.

As a latecomer to the Yangtze River Storage, in fact, as early as 2018, 32-layer 3D NAND flash memory chips have been mass-produced. However, in 2018, each of the 64-layer and 72-layer 3D NAND flash memory was already the main product, and it has already been fully laid out. The gap between the generation behind makes the Yangtze River storage did not attract industry attention at that time.

In early September 2019, Changjiang Storage announced the mass production of 64-layer 256GB TLC 3D NAND flash memory based on the Xtacking architecture, and this is also the first time that China has achieved 64-layer 3D Mass production of NADA flash memory chips.

Xtacking architecture

In addition to Yangtze River Storage, domestic companies are currently struggling to catch up. Yangtze River Storage, Hefei Changxin, which focuses on mobile memory, and Fujian Jinhua, which is dedicated to basic memory, form the troika of China’s memory market.

Fujian Jinhua focuses on the development of niche memory (Specialty DRAM), focusing on the consumer electronics market, and is expected to expand its own production capacity with its huge domestic demand market.

Different from Fujian Jinhua, Hefei Changxin directly hits the core mobile memory (Mobile DRAM) of the big international manufacturers, mobile memory It is already the product with the highest proportion in the memory category, and its power-saving technical requirements are extremely high, and the development is very difficult.

Although the three major domestic memory chip manufacturers are catching up with the international advanced level, it is undeniable that the memory chip manufacturers are still in an oligopoly In the competitive landscape, only Zhaoyi Innovation in China’s domestic memory chips has a market share of about 10% in NOR Flash. According to CINNO Research industry research, Zhaoyi Innovation’s NOR Flash global market share achieved a breakthrough in the second quarter of 2019, rising to the fourth in the world. And in the third quarter, it ranked third in the world.

However, the domestic market share of DRAM and NAND in key areas is currently 0.

In the NAND Flash market, Samsung, Toshiba, Micron, SK Hynix, Western Digital, Intel These six companies have monopolized more than 99% of the global share for a long time.

If domestic memory chip manufacturers want to catch up, I am afraid that only by working hard on technology can we make up for the historical gap. As semiconductor expert Mo Dakang once said, memory chips have highly standardized characteristics and a single variety, which makes it difficult to achieve product Differentiation requires manufacturers to compete with each other in process technology and production scale.

Yangtze River Storage X2-6070

Another model of X2-9060 128-layer TLC (each storage unit can store 3bit data), also has 512Gb storage capacity, the storage array area utilization efficiency exceeds 90% (storage array area / total chip area), I / O transmission speed achieves 1.6Gb / s high performance.

As Gong Yi, Senior Vice President of Changjiang Storage Market and Sales, pointed out in an interview with reporters, this product release shows that Changjiang Storage has basically leveled the international advanced level in the field of 3D NAND flash memory, and even has some Lead.

As a latecomer to the Yangtze River Storage, in fact, as early as 2018, 32-layer 3D NAND flash memory chips have been mass-produced. However, in 2018, each of the 64-layer and 72-layer 3D NAND flash memory was already the main product, and it has already been fully laid out. The gap between the generation behind makes the Yangtze River storage did not attract industry attention at that time.

In early September 2019, Changjiang Storage announced the mass production of 64-layer 256GB TLC 3D NAND flash memory based on the Xtacking architecture, and this is also the first time that China has achieved 64-layer 3D Mass production of NADA flash memory chips.

Xtacking architecture

In addition to Yangtze River Storage, domestic companies are currently struggling to catch up. Yangtze River Storage, Hefei Changxin, which focuses on mobile memory, and Fujian Jinhua, which is dedicated to basic memory, form the troika of China’s memory market.

Fujian Jinhua focuses on the development of niche memory (Specialty DRAM), focusing on the consumer electronics market, and is expected to expand its own production capacity with its huge domestic demand market.

Different from Fujian Jinhua, Hefei Changxin directly hits the core mobile memory (Mobile DRAM) of the big international manufacturers, mobile memory It is already the product with the highest proportion in the memory category, and its power-saving technical requirements are extremely high, and the development is very difficult.

Although the three major domestic memory chip manufacturers are catching up with the international advanced level, it is undeniable that the memory chip manufacturers are still in an oligopoly In the competitive landscape, only Zhaoyi Innovation in China’s domestic memory chips has a market share of about 10% in NOR Flash. According to CINNO Research industry research, Zhaoyi Innovation’s NOR Flash global market share achieved a breakthrough in the second quarter of 2019, rising to the fourth in the world. And in the third quarter, it ranked third in the world.

However, the domestic market share of DRAM and NAND in key areas is currently 0.

In the NAND Flash market, Samsung, Toshiba, Micron, SK Hynix, Western Digital, Intel These six companies have monopolized more than 99% of the global share for a long time.

If domestic memory chip manufacturers want to catch up, I am afraid that only by working hard on technology can we make up for the historical gap. As semiconductor expert Mo Dakang once said, memory chips have highly standardized characteristics and a single variety, which makes it difficult to achieve product Differentiation requires manufacturers to compete with each other in process technology and production scale.