The principle of the future supply chain layout is likely to become a balance between efficiency and safety. Enterprises should look for a spare tire when considering their business model.

Look at business with perspective. Super point of view, from the frontier observation of new business practitioners.

Special Observer | He Fan

Edit | Lu Fang

Special observer He Fan

Core tip:

1. Globalization will see a retreat, and the global supply chain will change from the principle of efficiency first to the principle of giving equal attention to efficiency and safety.

2. Import substitution may be the best business in the future, and spare tires will become an integral part of every business strategy.

3. Globalization has gone from the golden era to the local era. Appropriately reducing the degree of globalization will not damage China’s economic rise.

4. The future supply chain may be a platform-based supply chain.

How China becomes a world factory

China’s transformation into the center of world factories and manufacturing is actually a very special event. In the final analysis, we did the right thing at the right time and in the right place. There are three core reasons.

The first reason was the emergence of the Internet in the 1990s, and the technology of the Internet flattened the world. “New York Times” columnist Thomas Friedman wrote a book specifically called “The World is Flat”, telling this story.

Another reason was the fall of the Berlin Wall in the 1990s and the end of the cold war. During the post-cold war period, the relationship between China and the United States was relatively good. During this period, the post-cold war dividend or Sino-US cooperation dividend appeared.

The third reason is actually a fatal strategic mistake made by the United States in the 1980s, which led to the hollowing out of its manufacturing industry. It is actually not easy for China to board the ship of globalization, but after boarding the ship, it is very difficult to enter the first-class cabin from the third-class cabin, and it is still very difficult. An opportunity in China.

In the 1980s, the United States appearedA trend of thought is called “economic liberalism.” Economic liberalism tells entrepreneurs that their biggest goal is to maximize the interests of shareholders. To achieve this, entrepreneurs need to strip off all non-core assets and use fewer assets. To make more money, the stock will definitely rise.

For example, the legendary Jack Welch at that time, after he became the CEO of GM, he transformed a traditional manufacturing company such as GM into a financial company. The effect is of course very good, and the stock price rises quickly, but this area The negative effect is that the US manufacturing industry has been transferred out.

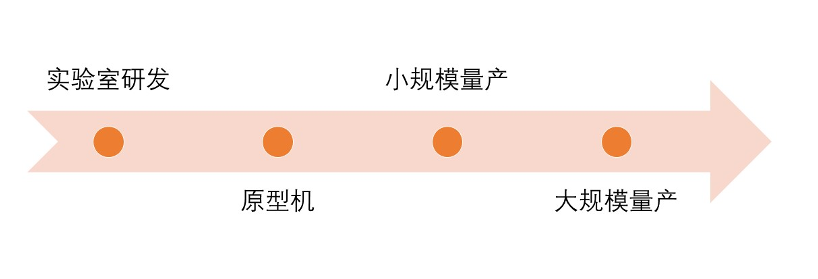

Manufacturing four steps

The development of the manufacturing industry has gone through four stages. The initial stage is research and development in the laboratory. Someone needs to put forward the idea, then make a prototype, then small-scale mass production, and finally expand from small-scale mass production to large-scale mass production. Between these four stages, from the previous stage to the latter stage are all thrilling jumps, and they may fall if they can’t jump through. Even from the current point of view of the United States, its research and development is still very good, can make prototypes, and may even be able to achieve small-scale mass production, but it has lost the ability to mass-produce many products.

It was at this time that some other economies began to develop, such as the Asian Four Little Dragons and China ’s domestic manufacturing companies. This is a large background for China to become a world factory and a world manufacturing center.

Will China ’s manufacturing industry be transferred to Vietnam

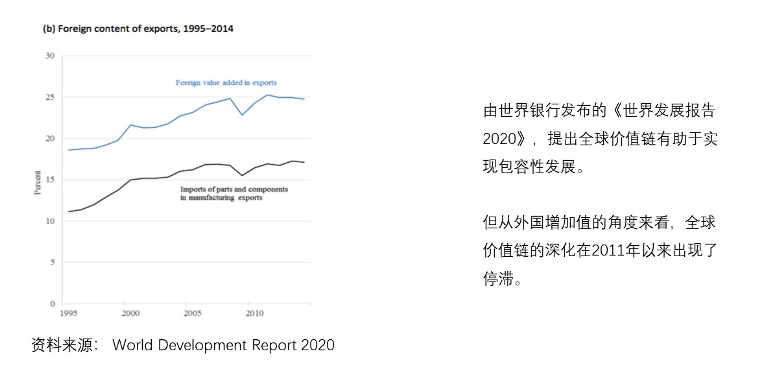

In the past, before the global financial crisis, we often said that the growth rate of international trade exceeded the growth rate of the world economy. There is a very important reason for this because the global supply chain is pulling the trade chain longer and longer, so Global trade can only grow quickly, but this cannot be pulled longer and longer. So for now, a general judgment is that the extension of the supply chain may have reached its peak.

Global Supply Chain and International Trade

From the World Bank’s graph, the growth rate of international trade is also slowing down. In addition to the impact of the global financial crisis, there is also a very important impact. The global supply chain has stopped expanding further, and international trade has also gone down.

Before the new crown epidemic, many people worried that many enterprises have moved to Vietnam. Will China’s manufacturing industry be transferred to Vietnam on a large scale?

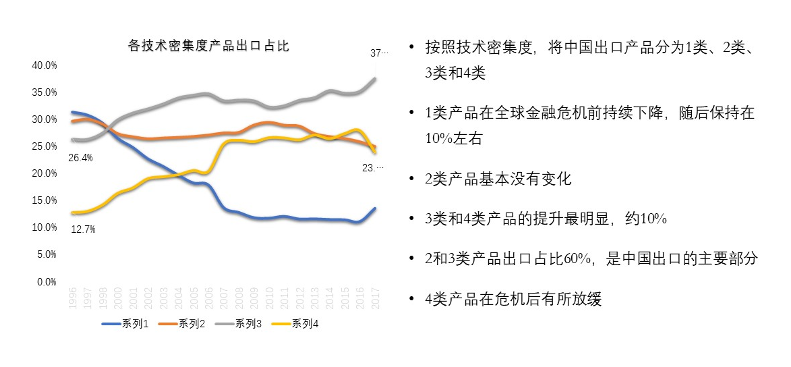

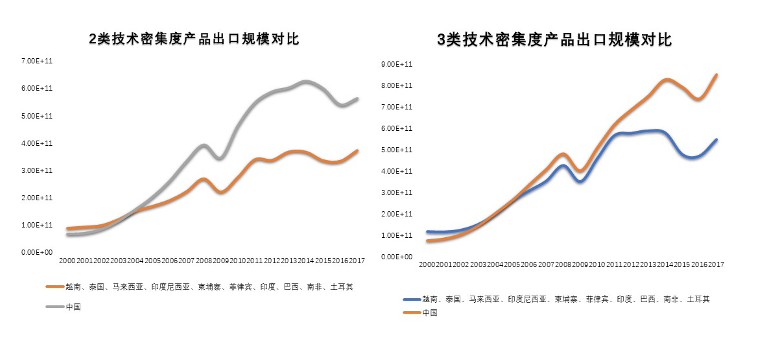

We made a simple analysis from the data. Our concern is that if China ’s export products are classified according to the degree of technology intensiveness, from category 1 to category 4. Category 1 is the one with the lowest technical level, category 2 is the lower-level technical level, category 3 is the upper-level technical level, and category 4 is the high-tech product.

China and the global supply chain

Let’s look at the changes in the proportion of these 4 types of products in China’s exports. There are several interesting conclusions. The first one is that we see that China ’s products with relatively low labor-intensive technology levels have been declining. But when did it fall? It fell in 2007 and 2008. That is to say, the upgrading and transformation of China’s exports started as early as 2007 and 2008.

Let ’s go to other categories 2, 3 and 4. There is basically no change in category 2, and the improvement in categories 3 and 4 is the fastest. Let’s take another look at the comparison between China and other emerging countries. If we compare Vietnam with China, it will be a little invincible. Because the volume of Vietnam ’s economy may be the same as the volume of our economy in a province of China. So we put Vietnam, Thailand, Malaysia, Indonesia, Cambodia, the Philippines, India, Brazil, South Africa, and Turkey into one new economy to compare with China.

China and EMs ’position in the global supply chain

What is the most obvious change in these two pictures? It is the advantage of China’s product exports. Compared with other emerging economies, there is a gap. This gap has not narrowed, but has been further widened. What does this mean? Back to the beginning, we talked about three reasons why China has become a factory in the world: Because the rise of China’s manufacturing industry is a special phenomenon that occurs in a special period, many other economies are reflected in the desire to catch up and have no chance . The volume is not as large as China, the dividends and marginal benefits brought by the Internet are gradually declining, and now it is trade protectionism, there is no post-cold war dividend. So we do n’t actually need to worry about other emerging economies replacing China ’s position in the global supply chain, but we can also see from the trade war and the epidemic that the impact on many industries is very serious.

What industries does the epidemic hit the most?

If we look at the simplest economic analysis framework, The impact of the new crown epidemic on the economy is nothing more than the three channels of supply, demand, and expectations.

The first is supply, because our current personnel flow is restricted, and even the flow of some commodities and logistics are also restricted. At this time, supply may have a negative impact. The second is demand. At the beginning, it was because of the closure of the city, and then isolation. Everyone stayed at home and did not go to the movies or go to the restaurants, so demand fell. Now after the resumption of production and re-production, there is another problem, that is, external demand, overseas orders have decreased. Finally, it is expected that the impact of the epidemic is that many people will consider that future income may decline, or because the market is not clear now, so he adopts a wait-and-see attitude, at this time investment and demand will be reduced.

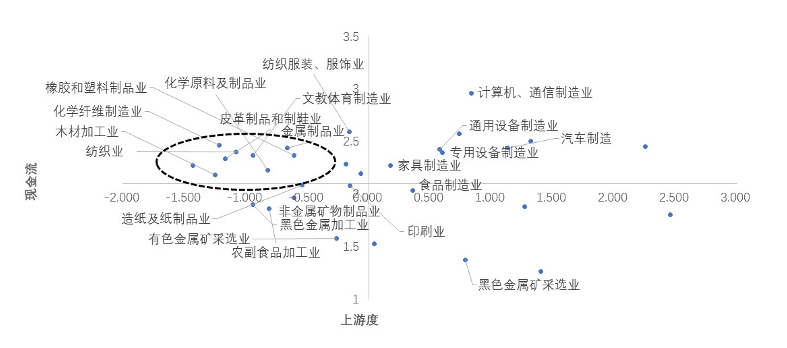

Which industries are more influential? It is clear from three dimensions, First, if more labor is employed in this industry, the impact may be greater. Second, if your industry’s position in the supply chain is downstream, then there will be turbulence in any upstream link, which will have a greater impact on you. Third, when the economic situation is not good, everyone should have more stable cash flow than others. Those industries that have sufficient cash flow reserves and relatively easy stable cash flows are relatively easier to pass the winter. some.

the impact of various industries

This picture reveals industries that are more vulnerable to impact from two dimensions. The horizontal axis is whether the industry is upstream or downstream? Another dimension is on the vertical axis, depending on the degree of labor intensity. The influence of these circled industries may be relatively large.

the impact of various industries

This picture is also based on whether the industry is upstream or downstream. The cash flow in this industry is stable and unstable, and some industries that may be relatively risky are circled.

The analysis concludes that the first is that the service industry may be hit hard. The impact on catering, tourism, and transportation is the most direct, but there may be some rebound after the epidemic. The most affected industries in manufacturing are the apparel industry and the chemical industry. These two industries have the three conditions just mentioned, so they are more vulnerable.

Some industries revealed that their dependence on the supply chain exceeded their imagination during this epidemic. Especially in the automotive industry and the communications industry, such as mobile phones, we can clearly see that it is in the supply chain at this time. The impact will be greater.

Some industries are relatively less affected by the epidemic, such as the pharmaceutical industry and food manufacturing industry. For example, the main market for soy sauce companies is domestic. For example, I saw a soy sauce company last year that basically didn’t use labor. From beans to soy sauce, it was basically automated, so At this time, the relative impact of these industries will be smaller.

Pattern changes in global supply chain after the outbreak

The impact of the epidemic on the global supply chain. First, we have to face a reality. Although we hope that China can continue to open to the outside world, we have to realize that trade protectionism will continue everywhere in the world. This is both bad news and good newsThe bad news is sure to have an impact on China ’s external demand. The good news is that during every crisis, some people may go retrograde and find opportunities in the process of retrograde.

There may be a change in this. The original principle of the global supply chain is efficiency first, that is, the good things I produce are produced by me, and the rest are all handed over to others to produce, so that the lowest cost and the highest efficiency can be achieved. . But this is actually globalization on the wire rope. Once there are some changes, it may fall. Now we have to consider the issue of safety, so the principle of the future supply chain layout will likely become a balance between efficiency and safety.

What changes will be brought about by combining efficiency and safety? You may have to prepare your plan or prepare a spare tire. Huawei makes a lot of spare tires, which gives us a good example. The spare tire turned out to be a professional term in the love world, but in the future it may be an important aspect that every company must consider when considering its own business model.

The ideal state is not to return to the era of complete self-reliance. No one can imagine that the world will fall back to the era of complete retreat, but the supply chain will change, so if we think about the future supply chain, I think < strong> The future supply chain may be a platform-type supply chain . Teacher Lu Feng of the School of Government Management at Peking University put forward a concept called a development platform. He said that the most important core thing of an enterprise is not a technology or a product, but a development platform. There is a group of people who have these experiences and know which technologies work, how to produce products, and how to sell products, to maintain their core competitiveness.

For example, it is impossible for an aircraft manufacturer to manufacture all parts by itself, but it must have its own development platform, and then can cooperate with others on the development platform. If you are producing screws, you can of course use the products of the best manufacturers in the world, but if it does not cooperate with you, you cannot always make the aircraft unable to produce because of a screw, so you should make your 2nd and 3rd place The name can be topped.

In the past, we would not spend resources to invest in the second and third places. Because it is a waste, it is a kind of redundancy. But now we will see that if you think safety is more important, safety first and efficiency second, then for tolerance of redundancy and investment in spare tires, we have to do it.

If you think according to this logic, there will definitely be many import substitutions in the future. Import substitution means that we are likely to make up for a very important part of the manufacturing industry in each supply chain. You can find along this line of thought. New business opportunities and new investment opportunities may be here.